Problem : Cardan Joint on Ford 9 Inch Axle Installed on 1973 Chevy Caprice

2023, November 14

Rant 1 Hello,

This is for my 1973 Caprice Classic convertible with a factory optioned 454. I recently installed a Ford 9 inch axle over the last winter in the car. Lately I've been having a vibration around 75 MPH. With that I took the tyres off the car and hauled them to a place to have them balanced. Two came back with the weights more or less in the same spot and two came back with weights in different quadrants. I am hoping this is the main culprit.

However I meant to return to the propshaft to install a new CV joint ball and socket kit and also install new Cardan joints. This is where I'm left asking, what's going on and did I miss something?

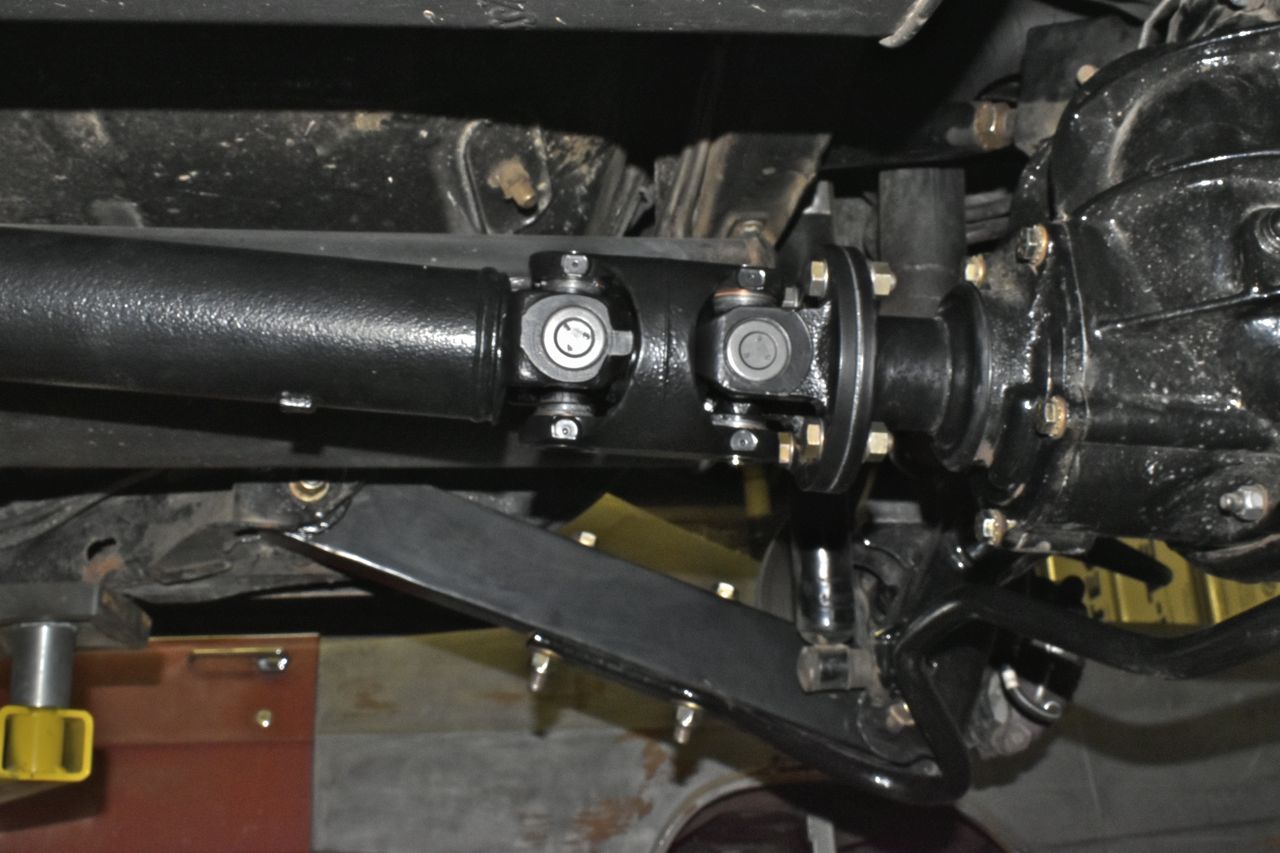

Here's the propshaft out of the car as of today. Nothing really special about it other than the CV joint at one end. It's the factory GM CV joint originally, but now part of it is from a '69 Lincoln to mate to the companion flange on a brand new Ford (Moser Engineering really) 31 spline big bearing 9 inch.

About 20+ years ago I replaced all three Cardan joints with TRW branded ones if I remember correctly. I haven't driven the car much since then, till recently anyhow and I'd estimate there is approximately 25K miles on the joints. Now when I adapted the Lincoln portion of the CV joint to it I used a Spicer branded Cardan joint out of the Lincoln because it looked really fresh, as in very recently. There were no marks on the trunnions. I have since put about 700 miles on the car since spring.

In other words, the 2 older Cardan joints have about 25K miles on them and the newer Spicer since installed has about 700 miles on it.

Here's the Cardan joint (Spicer) from the '69 Lincoln. Looks just peachy from this angle.

However, on the forward gear thrust side you can see the needle bearing imprints already.

And it isn't isolated to one trunnion, all 4 four have varying degrees of needle imprints on the forward gear thrust side.

Now the older ones with 25K miles are much worse.

They all had plenty of lube still in them, I just can't explain why the car is literally eating these with so few miles. Now I fully admit I love pressing the fun pedal, but I find it hard to believe that big block has so much torque it's literally squeezing the hardened needle bearings into the hardened trunnions on what I would think are well made Cardan joints. If these were some cheap Chinesium knock offs or something from A-1 Cardone I wouldn't look any further as to the reason.

Am I missing something obvious?

I bought 3 new Moog heavy duty Cardan joints, but other than that I don't know how to eliminate this problem.

Rant 2 The pinion angle centre line now matches the engine/trans crank-output shaft centre line exactly. The propshaft angle relative to the aforementioned centre lines is no more than 3 degrees and equal at each end and varies no more than 0.25 degrees through normal axle suspension travel. I spent a great deal of time and effort to set those angles close to textbook as possible as the original angle from GM was horrendous (that's why they put a CV joint on there). As you can see the older joints with 25K miles that were mostly on the factory axle and angles really took a beating over the years.

Rant 3 When I finished the axle install I ran the car to over 100 MPH on the lift with no tyres and there was no noticeable drive line vibration. Now since I have finished the new axle with the new gears and true trak I have been really enjoying the fun pedal as with a car that's 5000 lbs curb weight (rounded to 2 significant digits) any improvement in acceleration is enjoyed.

Now that I think about it, I bet the two tyres that came back from balancing with a wad of weights pasted inside the rim on different quadrants might have been the rear tyres and the other tyres the weights really didn't change much. I can't believe I tortured the rear tyres that much to effect that drastic weight change.

I know all those years ago after the engine was modified for high low end torque (think 600+ ft lbs at the crank at low RPM) to combat the weight and being stuck with a 2.73 final gear ratio that's when a stock Turbo 400 could not live in the car. It would blow the sprag assembly completely apart on any stock GM Turbo 400 transmission (I went through several transmissions before finding a solution). As I remember most of the transmission shops back then also said there was something wrong with the car in that it shouldn't eat TH-400's like that. In the end I fitted this 1 ton truck Th400 with the racing high count hardened sprag assembly in order to survive. Been fine for 20 odd some years after that. My transmissions have no shift kits, factory soft shifts only, although on full throttle it will bark both wide tyres on a soft 1-2 shift.

The front (singular) Cardan joint from the transmission side, also one of the older replacements (~25K miles) was really hammered on more sides than just the forward gear thrust side. I do not know what that is about. On the newer (700 mile) clean Spicer joint there was that grayish wear area from the Lincoln already on it, but that joint clearly has bearing imprints on the forward gear thrust side only of all 4 trunnions after being in my car.

If the driveline angles were out of realistic specifications shouldn't there be really funky wear patterns on some or all the joints. I am wondering what causes the needle bearings to be squeezed so hard as to imprint on the trunnions on the forward gear thrust side? Are these just soft joints and maybe the heavy duty Moog ones will rectify it? I wish I had a hardness tester. I hate guessing.

Rant 4 The car is a body on frame construction with a triangulated 4 link rear suspension. It is just like a 90's Panther, only bigger, wider and much heavier.

You can definitely see the outrageous propshaft angles from the factory, especially on that front singular joint at the transmission. Withcidentally that joint was the worst, it was really hammered with needle imprints probably because of the extreme factory angles.

Rant 5 Everything I've read and researched says the pinion angle must match angle of the centre line of the output shaft of the transmission (which also is in line with the engines crank, obviously) and that's what I've toiled so hard with to accomplish. Even the 3rd gen full size Fords (65-58) have a cam bolt on the upper control arm to dial in pinion angle to the engine and trans at normal ride height (very nice touch I thought). I dunno what GM was smoking on when they thought hymmm this is a good idea (see the original pictures of the original idiotic propshaft angles of the '71-'76 B bodies).

When I finished the axle install I had no vibrations other than the normal engine vibrations. The at speed vibration problem started a couple weeks ago. Which after seeing the amount of weights shifted on 2 tyres after balancing is probably the cause.

I know the CV divides the angle over two joints but there is still over 2 degrees of propshaft angle at normal ride height, which means each joint in the CV is seeing roughly one 1 degree still.

As a side note the big '69 Lincoln I pillaged the rear CV joint off and companion flange had two CV joints (front and back) with very little drive line angle, of which I'd estimate equal too or less than mine currently.

The question I'm fixated on at the moment is what else, besides sheer torque could impress needle bearings on the forward gear thrust side of Cardan joints? Do I just have 3 soft joints out of pure dumb luck or is there something I'm totally oblivious too?

If anything I've set up the propshaft similar to the 3rd gen galaxie, just has an extraneous CV joint on one end for now. But the Lincoln basically had two extraneous CV joints by the same logic.

Rant 6 I'm going back to the original GM configuration and judging from the extreme needle imprints on those older joints with just 25k miles I'm back to square 1 as those joints were obviously under severe stress under the stock configuration so that doesn't really solve the problem as I would expect more of the same.

I admit I am out of my comfort zone on the empirical side of this and am much more of a mechanical engineering book worm.

Rant 7 June 6, 2019. Just an update to this brinelling and vibration problem.

Since I had already purchased Moog Super Strength Cardan joints I am going to use them in this interim propshaft (need a new one made for the OD tranny eventually).

Now way back when, long time ago, when I young and really clueless. Just slightly less clueless now. I painted this rusty propshaft with Rustoleum. Let me clarify, I brush painted this propshaft with a heavy coat of rusty metal primer, then a slathering of gloss black molasses like paint. The reason I'm mentioning this is that it very well might play a role in what follows next.

It's thick. Well I thought to myself, that's probably putting the propshaft out of balance and it's better to soak all the paint and rust off this thing and just use a proper spray application of 1 coat epoxy.

So I did. In the electrolysis tank it went and all the paint and rust came off. About 3 lbs of paint came off! No exaggeration. So after that I evenly coated it with single stage epoxy satin black.

The tube was really pitted from years / decades in the Midwest.

New front singular joint.

New rear joints and ball and socket rebuild kit.

Here's the ball and socket rebuild kit.

Fully assembled.

My OCD wouldn't quit. Even the flange bolts are AN hardware with the correct shoulder length for this application.

Installed.

Well took it for a test drive and there's a wicked vibration in the floor now above 60 MPH. The car shaking vibration is gone (balanced tyres), but now this, that was never there before.

So I took the propshaft back out and hauled it into ABQ to Wilson Driveshafts. 50 dollars later it was rebalanced.

The blue tape is where the factory weight was. The new weights are in a different quadrant now.

Same on the other end.

Wilson's wasn't kidding when they said it was out of balance. Sorry for the clutter in this picture, there's a propshaft hiding in there somewhere.

The question I'm pondering is did I get just stupid lucky when I brush painted the propshaft all those years ago and magically balanced an already unbalanced propshaft or is there something really funky with the new Moog Cardan joints. Or both. This is really rhetorical now, but something to consider.

Anyway it went back in the car and whalaa smooth as silk once again. Although I did find out when taking the tyres to get balanced they are over 10 years old. I was miffed because I bought them less than 6 years ago through TireRack. So they sold me old tyres. So now it's time for new tyres. Now I really have an excuse to torture these and use them up quickly.

Now only time will tell about the brinelling on the Cardan joint trunnions. When the OD tranny is installed I will take apart this propshaft and inspect the joints. If there is still brinelling of the trunnions, then the next longer propshaft that will be made to fit will be fitted with racing Cardan joints as in doing research they are harder and a better material. Actually 4130 full hardened Chromoly joints that are designed to alleviate the very problem at hand.

And yuppers the weights are now on the same side, more or less. Whereas the original weights were 180 degrees apart from one another on the ends.

Dunno how that happened but it's back to rights now.

Me happy.

‹ the end ›