A Cool Engine Sold : 1966 Ford FE 352 Machine with Custome Made Parts

2023, November 14

352 FE fully machined with ground, polished and balanced crankshaft, custom machined Diamond pistons, Total Seal gapless rings, completely ported and polished heads with custom Ferrea stainless undercut valves and hardened seats. Plus an extra set of 1968 Ford 390 FE heads.

This was for a build that was cancelled and would make an excellent build for a street rod. Designed horsepower was to be approximately 440 horse @5600 RPM @ sea level conditions.

Have 4500 dollars just in parts and machine work.

The block is a 1966. It was line honed, decked true, bored 30 over, honed to match gapless rings, all oil port plugs are converted to threaded plug.

The crankshaft was cut 0.010" polished and balanced. The connecting rods you'll need are common 390 connecting rods. The piston pin height was altered to allow the more common 390 rod.

The pistons are forged moly coated custom made pistons. The top ring is gapless and the rings are moly coated. The oil rings are standard tension and the ring packs are 1.5-1.5-3.0 mm for less parasitic drag.

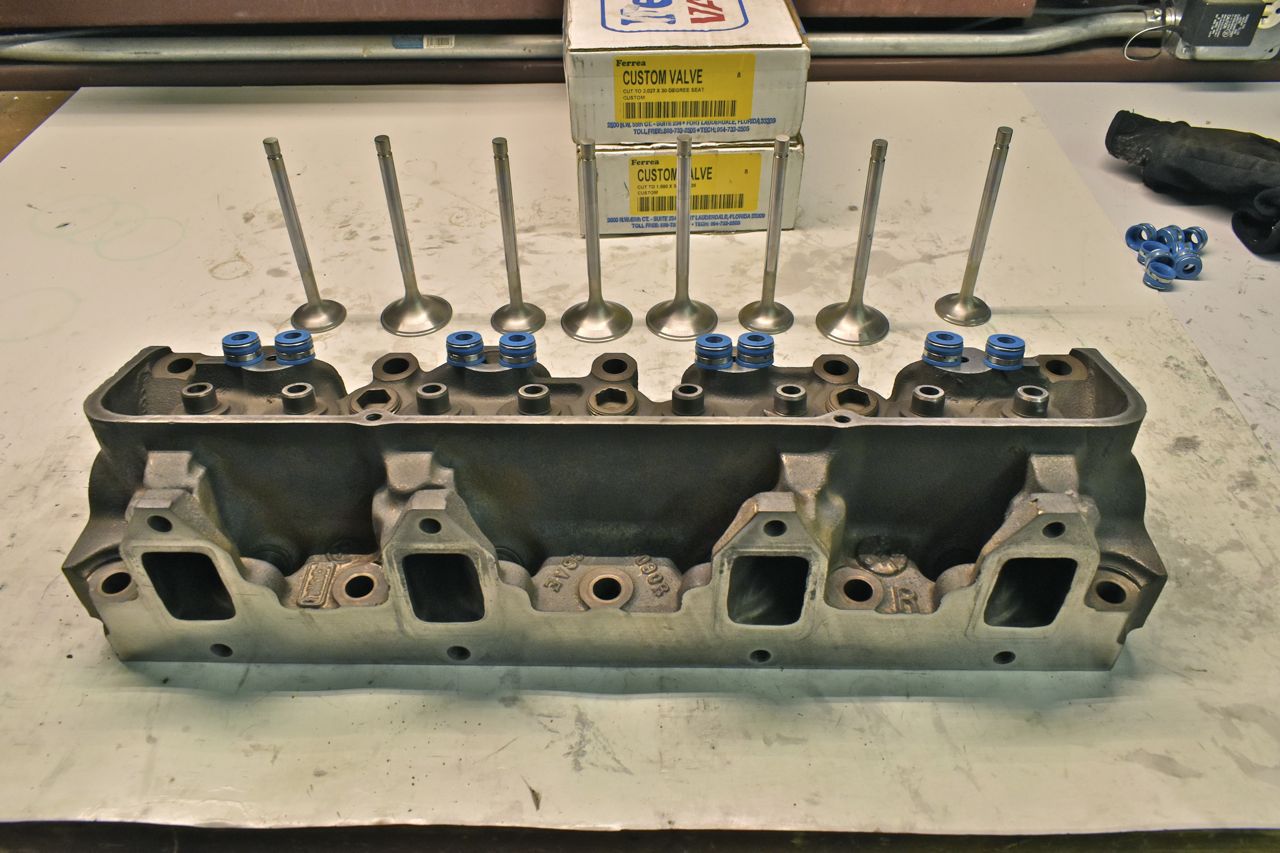

The heads meant for this application were ported, polished, decked and hardened valve seats installed. Custom made Ferrea stainless undercut valves were used. Positive pressure valve stem seals were used.

Also included are a set of used FE 390 heads off of an a 1968 Ford XL fastback.

Please see pictures:

Spare set of '68 heads.

Let me give you a little history of this engine and intended build. This combination should give you a really good idea of where this was headed.

The original intent of this engine was for a '66 galaxie 500 plain jane 2 dr. This was the original engine and thus the plan for the engine was to show the mid 60's 352 can be reworked to make it something viable other than the dog it's normally known for. I wanted to well eclipse the hp per CID mark and this set up was to yield around 440 hp out of a little ~357 (0.030 over 352) with over 400 ftlb's of torque starting out at a low RPM. The red line was 5800 RPM and peak power was modeled around 5600 RPM.

I had bought a Crane roller cam and push rods, Holman Moody bronze cam plate, SCJ oil filter adapter (Blue Thunder repop), Morel roller lifters, Precision Oil Pump's complete rollerized valve train, Cloyes true double roller timing chain, Mellings HV oil pump, Edelbrock aluminum intake, and much more, I think you get the idea.

The total cost was around 10 thousand just in parts and machining to complete the 352.

The '66 galaxie 500 2dr plain jane was scrubbed for a '66 galaxie 500 XL instead which came with a 390. It was decided to cut the losses on the 352 and use what I can out of it for the 390 build.

4500 dollars might seem like a lot to give up on, but compared to a 10 thousand dollar engine and a 50-60 grand total car cost of a body off frame restoration and modification, 4500 dollars is a small amount.

Now to answer your questions:

1. There is no cam included in this, it is going in the 390. What you see in the pictures is what's for sale.

2. The 428 has a different stroke and therefore a different compression height on the piston. You can double check but I doubt these expensive pistons would work for a stroker, even though they are modified to work with a common 390 rod. This 352 was meant to generate considerable power whilst retaining a smaller displacement for economy when just cruising.

3. The heads intended for this are the C6AE-R heads, the ones pictured with the hardened valve seats, ported/polished and custom made Ferrea stainless undercut valves. I just threw in a bonus spare set of '68 heads to make room on the shelf as I do not need them.

One last thought, I wasn't aware they made a C4 that mated to an FE big block.

When it came to choosing parts for the 352 build, you can buy off the shelf at Summit brand new Eagle rods for the 390. There are none to be found for the 352.

Since connecting rods have a life, ie so many compression and tension cycles, instead of having a custom set of 352 rods made and a custom set of pistons made, the choice was made to use the off the shelf 390 rod and compensate in the compression height.

UPDATE : Feb 13, 2021

Well the fella that bought it was going to use it in his old Ford truck. With enough money and technology infusion you can make even the most anemic of factory engines respectable. I was originally going to use this engine with just a plain Jane '66 gal 500 as it was the original engine for it. I had modeled this engine and chosen the parts to yield about 440 gross horsepower peaking around 5600 RPM. Whether the fella who bought it will outfit as such, dunno. But even with flat tappet cam, good induction and headers it should yield some impressive results.

Cheers.

‹ the end ›