Problematic Hydraulic Roller Lifters for the Ford FE Engine - part 1 of 2

2023, November 14

part 1 - part 2Hello all,

This is a long story with few pictures. It's a stream of rants.

Rant 1

I am wondering what brand of aftermarket hydraulic roller conversion lifters have worked.

The reason for my pondering is that I found my low oil pressure problem. When the lifter is at the top or near top of the cam lobe, the top land on the lifter is near enough at the top of the lifter bore and it hemorrhages out the lifter valley area when the oil is hot and thin.

Rant 2

I'm going to call Crane Cam's and talk to them because it's their camshaft and their parts listing I originally went by. However at the time of my purchase they were out of their lifters and said substituting the Competition Cams FE-MEL385 roller lifters would be fine. But it isn't. Now, Crane has their lifters back in stock at multiple places. I want to see if they can send me a drawing with the dimensions of the land heights so I can compare it to the Competition Cams version I have.

This engine project seems jinxed with the aftermarket parts. I had to pull the heads too as idle is really shaky and the vacuum gauge bounces horribly at anything under 1000 RPMs and it still flutters over high rev. I did a static compression check and cylinders 1 and 2 are leaking through the intake valves. Then there's a problem with the Edelbrock head. If I have to pull one head and intake I might as well pull the other and remove the valves and inspect those too.

Rant 3

So the Edelbrock head is supposed to flow as well or better than a cobra jet head. They have the larger stainless steel valve heads with undercut stems installed, they do not have that oil gallery casting hung low in some of the intake ports like the Ford heads have and they are aluminum. Now the weight savings isn't all that since the FE heads are so small anyway. But these particular heads I bought come all set up for a roller camshaft. In other words they have the higher springs required for the quick ramp times of the roller lobe.

Previously on building a 352, I wanted to just buy an aftermarket head, but the vast majority said that the oversize valve heads (pretty much all aftermarket FE heads) wouldn't fit the 352 bore because the bore is too small. Some said it fits fine. Edelbrock says it's a resounding NO — it will not fit. So I didn't want to take a $1,200 gamble with a head and I took out the original heads and to see where I can improve flow. Talley up: (1) a custom set of stainless steel undercut stem valves with a stock head size, (2) brand new beehive springs for a roller cam, retainers, locks, (3) all the porting work done to the head, and (4) hardened seats installed along with all new guides and required decking for a true surface, and it's more expensive than the Edelbrock brand new head without the performance.

It was such a hassle to try to upgrade a crappy old FE head it's not worth it in my opinion. Plus the machinist was worried about cutting into a water jacket when installing the hardened seats which makes me nervous if it will crack with future use.

Of course I wouldn't expect valve sealing problems with a brand new head either. I've had nothing but bad luck with aftermarket parts for this engine. Even the ignition system components are wrong and I bought everything for a 1976 Ford FE 390. The ignition coil was too powerful and jumping to multiple posts under the small cap in the distributor. Even with spark plug wires in the resistance range of 1.4K ohms +/- 200 ohms it would fire multiple cylinders. I couldn't get a stable timing light on #1. I put the crusty 50 year old points coil on the Duraspark module and it's fine. These things are just annoying beyond belief. Now I have to remove the top half of the engine and still figure out what to do about the lifters. I might as well just pull the engine back out. Not to mention what to do with the heads.

Rant 4

I'm still pulling my hair out over the lifter dilemma. Competition Cams says this will work and shouldn't be a problem, but the top machined land is coming close or out of the bore and dumping pressurized oil into the gallery. I just talked to Crane Cams and I have dimensions on their roller lifter that is available once more. I'm not using a wild cam either. It's a 286/290 duration with a 563 lift. I just don't know. Competition says it should work just fine, it doesn't, all I can do is now is take measurements.

Rant 5

I probably should start by answering your question about what the intended use of this and the other galaxies will be for. All we wanted were nice old cars with big blocks that had a bit of grunt to them when needed. We didn't want a modern stock Camry blowing the doors off an old car with a big block. It just shouldn't be .

So the intended use for any of my classic cars, including the LTD are complete daily drivers whether to work, cross country, shopping, to a car show, or Saturday night at the drag strip.

We would only use our Mercury Grand Marquis for the winter snow we occasionally get, like today in fact. Both those Mercs have traction control and they do absolutely fantastic in 6 inches of snow. Weirdly with the same type of tyre, my old 1993 Grand Marquis actually does better than the 2004 Grand Marquis. But I digress.

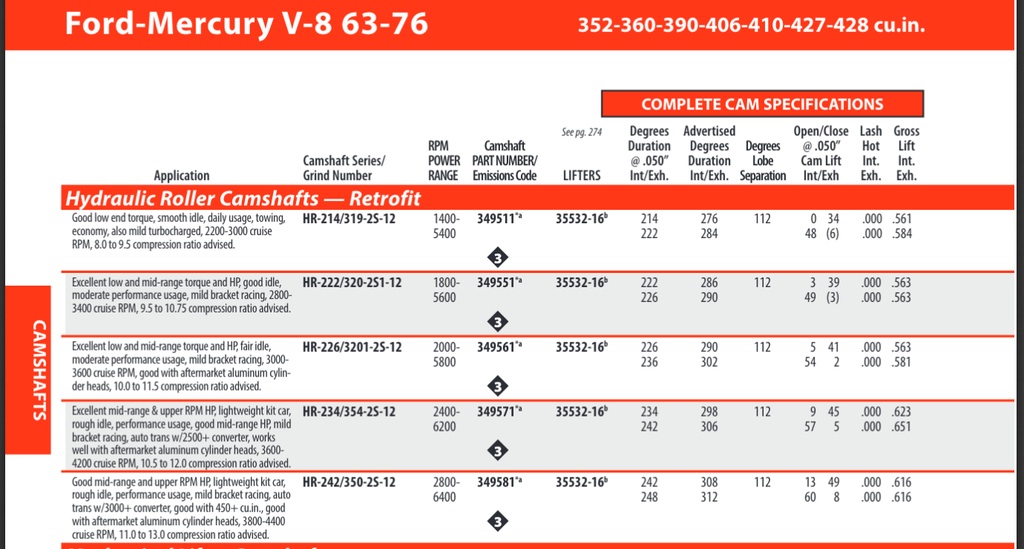

Back to the lifter problem. Here's a snippet of the Crane Catalogue. The cam isn't that tall on lift, compared to some of the other ones.

The one I have is the HR222 series (2nd one down from the top). Crane is indicating that you can use 0.651 lift cam with a roller lifter. This is why I am scratching my head. Unless the alleged Comp Cam substitute can't handle this or is machined incorrectly.

Here's the Comp lifters I used. It's an 8934 part number meant for FE and 385 series.

Now looking back I'm pissed at myself for not catching this.

You can see how how the top machined land is sticking high up and the that the lifter bore isn't the machined diameter all the way to the top in the block. There's a larger lip area just before the top of the bore. It's kind of hard to see in the picture, but this is where the oil is spraying out from when the lifter is at or near the top of the cam lobe.

About my philosophy regarding this drivetrain. Well I thought it would be novel to be able to have a calm daily driver under normal driving conditions, but open the taps and you'd better hang on. I spent $10,000 dollars on parts, machining and countless hours of research, prepping and assembling for this engine to reach that goal; at this point I really don't want to start dialing it back and research parts that will work as more or less promised, for lack of a better word, by the Crane Cam catalogue.

If I knew it was going to be this much trouble, for 10 grand I could have bought a really nice newer family crate engine and mated that to a nice over drive automatic and just scrapped this FE and C6 from the get go. In fact, it's looking like that's the route to go with the other galaxies and just scrap their original FE drive lines. Of course that's annoyance speaking now. I've come this far with it and even though I'm really annoyed with the multitude of troubles I do need to see it through.

Hopefully the Crane Cam lifter will work. I have to remove one set of Comp lifters from the engine and take measurements. I wonder if I can snake one set through the hole in the intake without removing the intake. Hmm.

On another interesting note, Crane said the additional oiling from the pushrods and lifters into the FE rocker should be no big deal. My head is spinning.

Rant 6

The 'b' next to the lifter number on the Crane stuff means it needs special length push rods. Which you'd expect as the roller lifter is taller.

As a side note I did manage to snake out a lifter set through the intake, actually it was easy peasy. It is an Edelbrock aluminum intake. So then I compared Cranes critical dimension to the Comp and it's near enough the same, which means the Crane lifters will suffer the same problem. Which now points another finger at the camshaft.

In looking at the picture with the lifters in the valley area, even those that are down are sticking up too high. If they could drop the base circle by 0.2 inches I think problem is solved. But yes that would require different length pushrods, again.

I find it hard to believe that Crane would offer a poor design. I mean the cam dialed in on duration ˚ and lift height. To pass a cam shaft from DV (design validation) through PV (production validation) with no one catching a base circle size error, I find amazing and disheartening all at the same time.

Well since Crane is now closed till next Friday I know what I'll be doing over the holidays — I'll be taking the engine back out as it's also a confirmed kill on the Edelbrock head as I loosened the rockers to make sure nothing was holding the intakes open. And yet still cylinders #1 and #2 are leaking back through the carb when pressurized with about 100 psi. So there's something amiss with that brand new head.

It'll just be easier to remove the engine and put it back on the stand for all this. As much as that really stinks to have to disconnect all that and pull the radiator support back off. I'm not particularly thrilled..

Hope you guys are having a better day than I. Rant 7

As a side note, I'm not sure how much they can reduce the base circle of the cam, there's not exactly much left.

Rant 8

Rant 8

My better half had a 1998 Camry that burned copious amounts of oil. She bought it new and got her money's worth. With +200,000 miles, it still would blow the doors off our 2004 Grand Marquis which we bought to replace it. To make it worse, the 2004 Grand Marquis was quite a bit quicker than the 1966 galaxie fastback we drove for a bit with a 352, and also quicker than the 1968 XL fastback with a 390 Y code.

That's just sad. really really really sad

Rant 9

Agh these are the fun rants and not me whinging on about aftermarket parts.

So the 1966 galaxie that we had driving was colored 'red and primer' and it had 30,000 miles on it. And believe it or not, it was all original with 352 factory 4V and equipped with the original dual exhaust system with the Ford mufflers. It was replete with an FX slush-o-matic and a light duty (small bearing) 9" with 3.00:1 gears.

The1968 XL fastback was nearly original as well, with what looks to be 68K miles on the clock and a 390 with 2 jet carb. It was originally single exhaust, but someone put duals on it, a C6 and the heavy duty (large bearing) 9" with 2.75:1 gears. These things were slow, ran smooth and tuned to factory specs but just gutless warriors.

Now to be fair our recent addition, the 1968 four door hardtop LTD with the Z code 390 is actually pretty snappy. Well when I say snappy I mean faster than a kid on a skate board downhill. It's a 390, factory 4 jet, factory dual exhaust, C6, heavy duty 9" with 2.75:1 gears. Or least the tag on the rear end decoded as such, I can't see any evidence that it was monkeyed with.

If anything the two 1968 galaxies are a good comparison, because they are pretty much the same except ones a Y code (low compression, most likely a "smaller" cam) and the other a Z code 390.

Now my 5,000 pound yacht of a Caprice Classic convertible with its 454 will beat these cars hands down. But that took work to that engine to pull that off because it too was a gutless warrior when I first bought it.

I don't want the 1966 LTD to be a gutless warrior.

Rant 10

My old Caprice convertible at the track will pull a low 15s in the quarter. For a land yacht that's 5,000 pound curb weight it's pretty darn good, especially because it still has the cheesy factory 2.73:1 rear axle gears and open diff too. Setting up the engine for extreme lower end torque (think 600 ft/lbs at the crank at >2200 RPM), and with not much HP, it's only around 350 or so, was the way to work with a high mass car with less than optimal gears. Of course I was still learning and it turns out the stock, or any stock Turbo 400 (equivalent to a Ford C6), cannot take that combo. I went through 6 transmissions total and had it out 10 times before I learned what upgrades a stock 400 needed. I haven't had a chance to install the new axle with the 3.25:1 gears in it and a Tru Track diff. (a 9" axle I had made to fit the GM).

I also plan on replacing the Turbo 400 with a 4L80E (equivalent to Fords 4R100) and use the aftermarket kit to increase the ratio of 1st and 2nd gear close to that of the 4L60E (similar to Fords 4R70W). The combined improvement in rear axle gear ratio along with a much higher 1st and 2nd gear ratio should make the car really scoot.

After that I can change cams in the 454 because I do not need crazy low end brute strength to get the yacht up to speed. I can effectively trade in some of the lower end torque for more horsepower at the upper end since the new gears will be countering the high mass of the car.

It's funny, a long time ago, when I'd frequent Union Grove Race track with the convertible, there was a huge crowd of 94-96 Impala SS's (long before I owned mine) and during the grudge match nights, the track would allow just those SS's to race each other for a bit. Not one of those cars could break into the 15's. They were low to mid 16 second cars from the factory. This is when they were practically new.

And those Impalas have a 4L60E transmission, an LT1 5.7 litre engine and a 3.08 posi from the factory. The Impalas are about 4,300 pounds, but the 4L60E has a wild first gear ratio, I think 3.06:1, and those cars would accelerate very good in first but fall flat on their face in second, 3rd, and overdrive. How sad, when back in the day of the touted limited production 94-96 SS Impalas, that they can't even break into the 15s.

Ugh. See I love talking about topics like this.

Back to the FE engine. Regarding valve lash adjustments on the #1 and #2 cylinders and if the valve train isn't slightly holding them open on the 390. Well to be sure about the issue, I loosened the rockers completely off the valve and those two cylinders are still leaking back through the carb. It's not much but I can hear it through the air horn. It is ironic that the 2 adjacent cylinders on a brand new head assembled at the factory would be leaking. It was packaged well, so I can't see it being damaged in shipping. You can probably drop it off the roof of the UPS truck and it would be fine.

I also didn't see any signs of damage when I measured the volume of each head. Assuming these heads are CNC'd, one possible explanation for the flaw would be if the machined hiccuped or the tooling broke/chipped while machining the last two valves or seats.

Because the heads came completely assembled from Edelbrock I didn't feel the need to disassemble and inspect, and that's where I went wrong. I had a silly notion that a $40 rebuilt starter should be inspected because it's cheap but a $1,200 head would somehow have better quality checks. Turns out it's the other way round in this case.

Oh well live and learn.

Cheers!

Click here to continue to part 2