Problematic Hydraulic Roller Lifters for the Ford FE Engine - part 2 of 2

2023, November 14

part 1 - part 2Rant 11

Took a day an a half to dismantle the front end to get the engine out. I was able to get it back on the engine stand late last night. Before I removed the intake and heads I thought, I'd better check the leakage one more time and with the headers off I could listen better to the exhaust side of things. Geeze, either I must have been deaf or the other head just decided to start leaking as well.

Bloody hell, I guess I'll be sending both heads back to Edelbrock. I took a video of it running and you can see the vac gauge going bonkers at idle and the engine shaking. #8 is leaking through the intake as well. And a couple of them have the tiniest leak through the exhaust also. This is really disappointing.

I removed the intake last night and I thought I had lost my mind, but all the lifters were sitting in the bore much lower than the picture I had posted earlier. I had forgotten but I had already exchanged those lifters once with Comp Cams because I thought I did catch that problem initially. But I didn't..... I still missed that the oil hole and cut out are out of the bore at lift. So this is the second set of lifters from Comp Cams and they are still not right.

It's really pointing to the camshaft now, I mean there's only 3 things involved with this problem; the block, cam and lifters and I find it hard to believe the block is some morphed FE that magically found it's way into an LTD on the factory assembly line.

Sigh.

Rant 12

Shame on me for not checking every single part I put on this engine. I should have done the static compression check after I put the heads on originally. I'll know better next time round.

Actually the only used parts of this whole engine are what I believe to be the original block, crank, and front dress from the car.

Here it is as we bought it. There is 96K miles on the clock. Car sat in a garage since 1983 and all paperwork from the time it was bought brand new up till 1983 was in the glove box. I tend to want to believe it's all original, well sans the Jerry can in the lower right . Silly thing still had refrigerant in the air con lines.

Rant 13

My fault I should have better stated the switch on the Comp lifters. It was the same part number swap with Comp. What happened came flooding back in the ol loaf when I saw the disparity last night. It's the same part number from Comp when I had talked to them, they said the set I had was an old design and they lowered the machined lands. The actual height remained the same. The part I didn't catch 2nd time round was that the oil hole and notch on the side was still the same height and that's what is jetting oil out the side at lift. And these are the drop in replacement for the Crane lifters, allegedly.

I know what you mean about that cam not being able to go much lower on the base circle without going into the core....

I just found a website that someone did a build on a 390 very very very similar to mine.

http://www.squarebirds.org/simplyconnected/390Build/NewParts.htm

They don't seem to have any problems, but they are using Morel hydraulic roller lifters with a Comp hydraulic roller cam. From the pictures the Comp cam looks like the Crane cam. But when I went on Morels website they have hydraulic lifters with 2 different size wheels and the oil hole is perpendicular to the axle centreline.

Now I didn't even consider the significance of the oil hole locations until a kind person in the other forum listed this site for cams in FE's:

http://diyford.com/camshaft-lifters-guide-ford-fe-engines/

I'll agree even with the head oil port plugged off, there's still loads of oil being dumped atop through the push rods. I mean about 3 -4 times the volume that my BBC has being delivered to the rockers at idle. That's with the oil feed plugged in the head.

The Comp Cams lifter oil holes are on the side (parallel to axle center line) and from the pictures Crane lifters also have the hole on the side. If there is truth in this, it must be an internal difference, because it certainly wouldn't make a difference where the oil hole is located in the pressurize oil gallery. The Morels have the oil hole perpendicular to the axle centreline.

And before Christmas when I talked to Crane I did ask again about oiling though the pushrods and he was confident it wasn't a problem with the FE.

Now I'm back to the basic 3 things as problems; the block, the cam and the lifters.

I can't see the block being weirdly different than the other 390 FE's that this combo will not work. I can't see the Crane camshaft being cut wrong, because it dialed in perfectly and there is no solid roller equivalent with the same specs (thought maybe it was misboxed and maybe a solid roller would have a larger base circle). Not to mention are 2 sets of the same part number Comp lifters wrong and are supposed to be drop in replacements for Crane?

Then I have Crane telling me push rod oiling is no problem for an FE, when I can clearly see it's still too much oil atop.

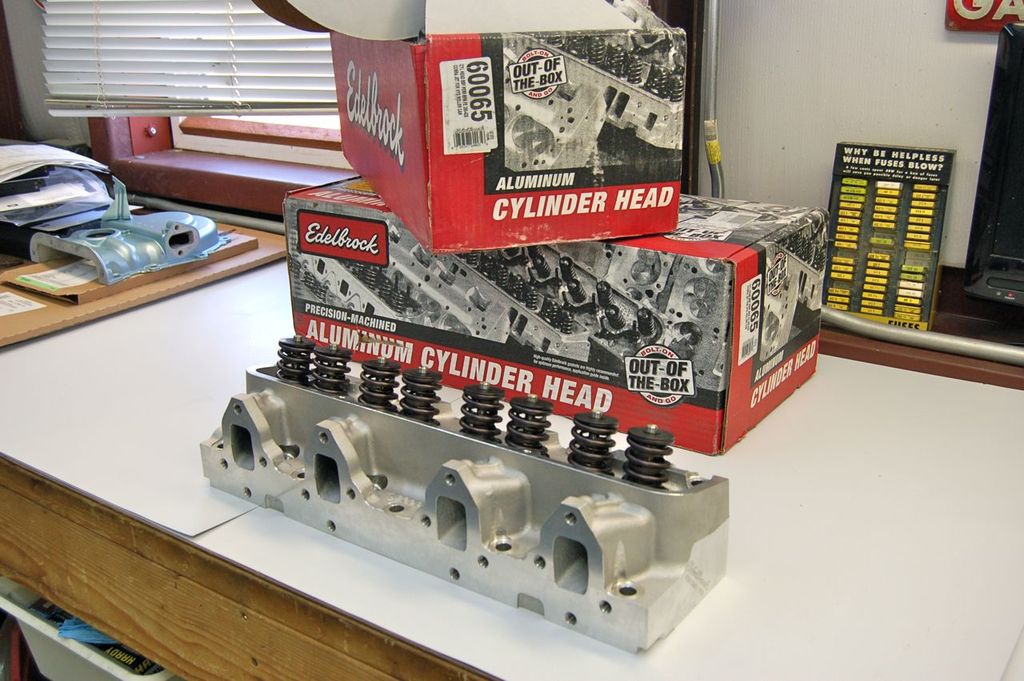

Add in 2 defective brand new Edelbrock heads.....

So this is what insanity feels like.....

Sigh.

I'm going outside to hug my Caprice Classic now...

I may be some time

Rant 14

OK just back in from the shop....

I think I have found the problem. It's the block. Pictures are worth a thousand words, sooooooooooooooooooooooooo

This is the pic from 10 minutes ago with the second round of the same part number Comp Cam lifters (8934). See how these redesigned lifters have the machined portion actually in the bore even on the base circle of the cam.

Just to regurgitate, the old edition of Comp Cams 8934 lifters same engine.

Even with that I didn't catch the oil hole and notch were coming up and out of the bore slightly.

The oil hole has a notch that cuts into the upper machined land of the lifter body this is just coming out of the bore at lift and jetting the oil.

You asked did I see oil shooting out whilst it was running... the answer is sort of. There was a deluge of oil still coming out of the rockers and it distracted me from what was going on inside the valley when it was running. So what I did was run the engine till good and hot (oil thin), then quickly popped off both rockers and pulled the dizzy and then manually primed the thing with piping hot oil. What caught my eye besides the crazy oil pouring out the roller tips was oil squirting up along side the pushrods through the intake and head push rod holes. That caught my attention!

Playing with the starter and bumping the engine and with the manual primer going oil would only jet out the lifters that were at or darn near full lift and very little seepage around the lifter when not at full lift. And it was jetting out the sides at full lift much like a lawn sprinkler.

Now here's the reason I believe as I just came to find out by comparison.

The actual lifter bore doesn't begin until well below the edge of the apparent lifter bore.

Then in hit me, I'm such a dunderhead sometimes, I have 3 FE blocks sitting in the garage, so I dug those out.

This is the 1966 352 that is yet waiting for me to put together fresh from the machine shop. The lifter bores start practically at the top with just a chamfer.

These lifters will work in this block. So onto another one.

This is also a 1966 390 'Y' code 50 seemingly horsepower delight, it also has lifter bores starting at the top with just a chamfer.

I couldn't get a picture of the '68 390 because of where it was at but that one has recessed lifter bores much like the 1966 390 block in question.

It's like Ford was doing willy nilly machining on these things..... whomever was on that operation just did what they felt like that day.

I suppose the good news is I can use these lifters in the 352. That bad news I need to buy another set of magical lifters that'll work in this block.

The other possibly good news is thanks to another kind fellow I think I found a set of magical lifters. They took a measurement of the Morel lifters and the oil hole almost 0.2" lower than these Comp Cams. That'll do it. I put in an email to Morel (no company phone number, weird) and waiting for a confirmation on that dimension.

That would solve the mechanical dimension problem and hopefully a good portion of the oil control. Now onto the whole magical event of rocker oil control based on where the oil feed hole is located on the lifter body. I've never come across this before, and quite frankly I hope I never do again. But if by chance this is true, then it explains the copious amounts of oil going to the top end. It's not a question of drain back, that's fine, it's a question of too much being let out.

Unlike the OE rocker system that only lets oil out the rocker when it rocks to one location, the Precision Oil Pumps have a concentric ring around the inside of the rocker always letting oil out through a large hole on the roller tip end. There's no way you could ever hope to pressurize the rail they sit on, not even with 5 HV oil pumps somehow attached to the engine. Nope, just not going to happen. So all you really can do is just restrict like mad the oil to the top.

I thought the lifters were supposed to actually meter, these are not really metering diddly. So in this case solid pushrods will be needed with these lifters. In order to save time and withcidentally money if the Morels are a good fit mechanically and because they seemingly have the magic oil hole perpendicular to the roller axle if they should actually meter I might still be lucky and just leave it push rod oiling. If not, then since I can't find anyone with special non-stock length solid pushrods I'll have to have a set custom made and go back to a strict orifice on the head port and let oil into the rocker shaft that way.

I'm going to go and hug my Caprice again, maybe even caress its 454.

I've had enough of Ford for one day...

Rant 15 and Conclusion

So this is where I'm at as of today, I purchased a set of Morel lifters p/n 5329, that should solve the mechanical dimension problems based on the verified dimensions the sales rep gave me. I also cleaned both heads meticulously tagged them and wrote up a synopsis for Edelbrock and shipped them out today.

I really hated to dole out another several hundred dollars in lifters, shipping heads (also very expensive) and new gasket sets, but it has to be done. I'm hoping the Morel lifters will magically meter oil to the heads (unlike the Comp Cams) through the push rods and I can just continue to use push rod oiling and my oil pressure problems will be a thing of the past. If not I'm not sure if I can restrict the pushrods oiling hole reliably. I may have to go back to a custom set of solid push rods and oil through the head port.

It makes perfect sense to me about the push rod end possibly lacking oil, but other people have used POP parts with solid pushrods so I would assume it's getting enough oil based on no complaints I have found.

Now I just wait....

It is tempting to hunt down some old 396 Chevy engines and use those for the remainder of the galaxies yet to go. I can get more power out of those for a lot less due to the mark IV's head, plus a 396 Chevy is ~ = to a Ford 390 bored 30 over (395 and change). At least you could take a 50+ year old mark IV and still bolt a modern overdrive transmission to it like a 4L60 (aka 700R4 using old nomenclature), 4L60E, or a 4L80E. It takes an expensive adapter to use a modern overdrive on an FE. But to be fair, is there a Ford overdrive that bolts to the 385 series engine? It seems to me every 460 I've seen up till the late 80's always had a c6 behind it. Did they make the 4R100 with the 385 series bell housing?

My Ford engine experience is limited, I've only really spent time on the FE's and the mod engines. Don't even get me going on the silly single overhead cam Mod engine. I hate working on the Marquis with that huge (bigger than a BBC) engine taking up all that room and having less torque than an electric snow shovel. But in looking at the 429/460 it's kind of apparent to me that it's a BBC in a Ford wrapper. :oops:

The heads are almost a dead knock off of Chevy's big block. However of all things they should have copied was moving the oil pump and by default the sump to the rear of the engine, because oil always moves forward under hard acceleration. :confused:

hehe- sorry had to.

Now I know I'm knocking Ford hard here, but I'll knock Chevrolet too. So to be fair all things I dislike about my Caprice. First, why does it have to weigh 5000 pounds for a Chevrolet passenger car, when the 3rd gen Ford full size is 1000 + pounds lighter with a big block. That's ridiculous, it's like GM found a sale on collapsed white star alloy and said, hey let's make our cars out of this.

All that weight ruins handling, acceleration and fuel economy. I have a spare transmission cross brace for the Caprice, it must weigh 40+ pounds! where as the 3rd gen galaxie is just several pounds. why?

And GM axles, I loathe those Salisbury axles, what a pain to work on. And you bet Ford had a fantastic 9 inch and that's why as soon as this '66 LTD is rolling and the lift is free, that brand new Ford 9 inch I had made for the Caprice is actually going in the Caprice and as for that 12 bolt GM thing it came with from the factory out you go.

Every car maker has it's good point and flaws. I've never owned a Chrysler product, but regardless I like my Caprice and I like my 3rd gen galaxies regardless of the annoying at times niggles they present. Sometimes it's just fun to poke a little fun at them.

Cheers and Happy New Year to you and all !

‹ the end ›