1965-1966 Ford FE Engine A/C Idler and Tension Pulley Rebuild - part 2 of 3

2023, November 14

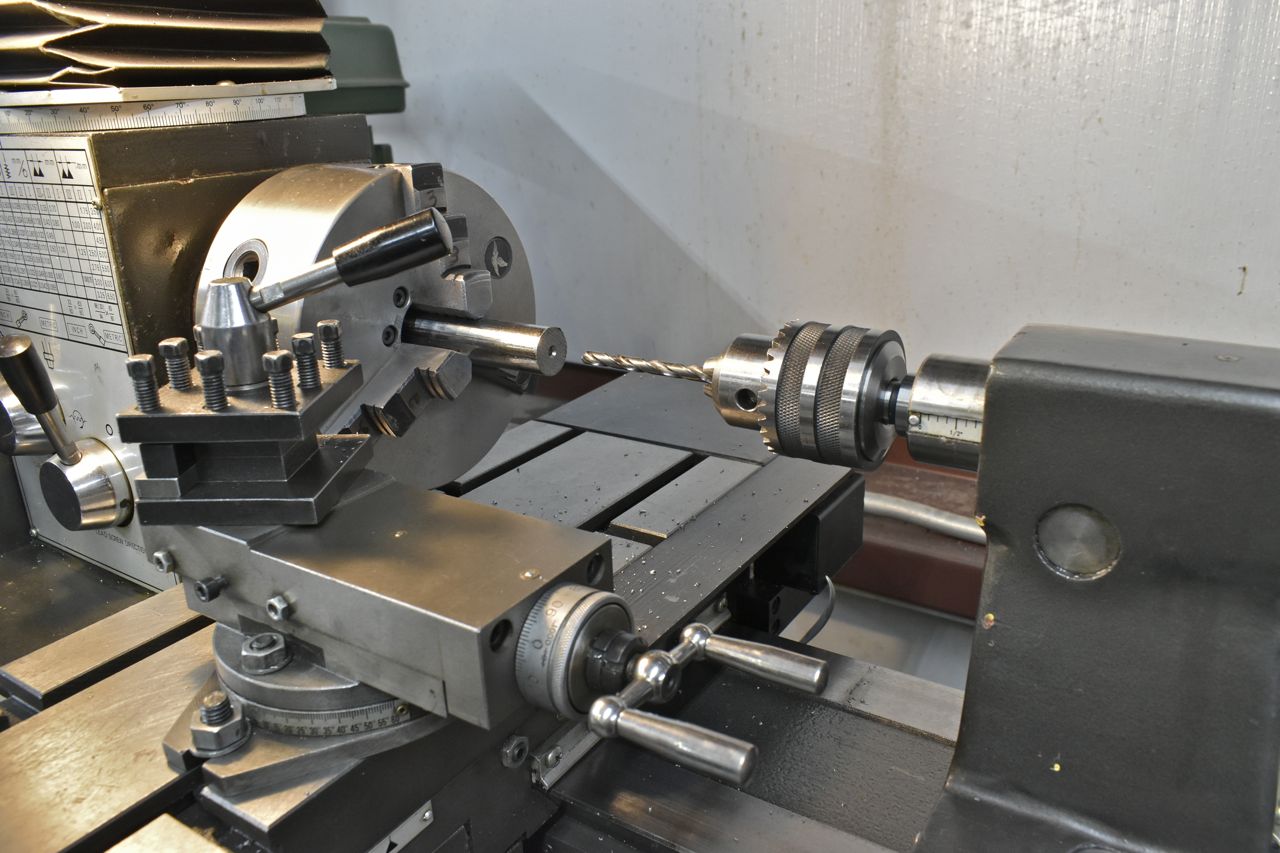

part 1 - part 2 - part 3I need a smooth surface to take measurements so a small centre drill dimple to ensure a smooth face cut first.

Face cut

Here's where you need patience and be able to measure pretty accurately. I do not want the shaft to protrude from the bottom of the tension base as it needs to be flat on the underside to slide and adjust. This is were I eyeballed the rough cut. Now I need to figure out the height of the shoulder to cut in the shaft as the stop.

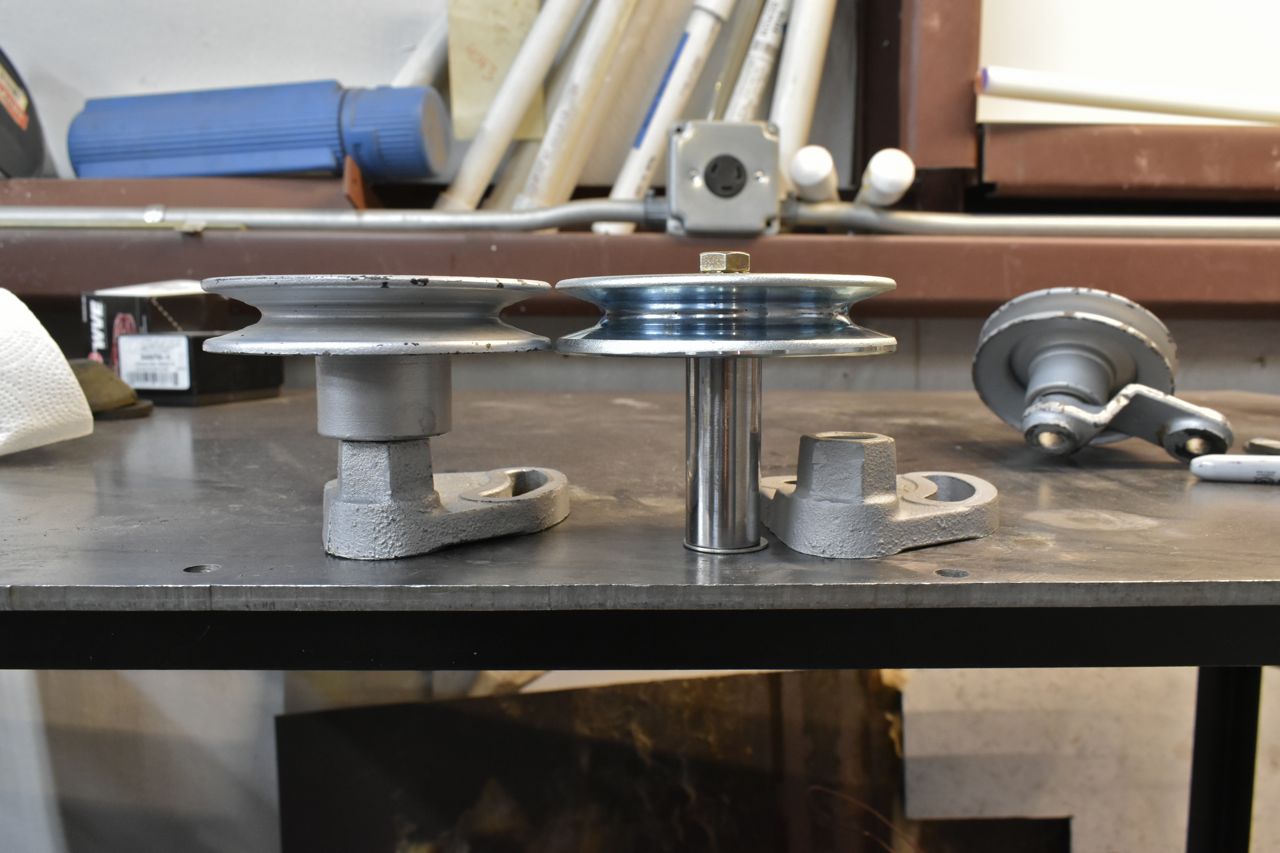

Here's where it's not so straight forward. In 3 sets I've done, the bases are not the same height on top. Here's how these were designed and built back in 60's. The bearing is integrated into the pulley. The shaft on the original is actually the inner race and that shaft is tempered full hard and there is no shoulder. When they were pressing these together they had a jig that would stop when the pulley was at the required height. Therefore they did not need another manufacturing step to assure all the bases where machined at the same height. This saves them money on high volume runs.

On my solution, my shafts are only 3/4 hard and so I leave thicker and since it doesn't pay to make a jig for the press I need to accurately measure the shoulder to cut on the shaft as the press stop.

With that I shim up the shaft until the pulley sheaves are in alignment. I measure the base height and shim and then am able to ascertain the height to start machining on the shaft for the shoulder.

I also measure the bore in the base. I machine and polish the shaft till it's 0.0005" - 0.001" oversize for a good press fit.

The Locktite acts as a sealer to keep any moisture ingress from causing corrosion between the pressed metal parts.

With a little patience it turned out well. Just a reminder being a hard material to machine it takes bloody forever to cut it down. One pulley is hours of work.

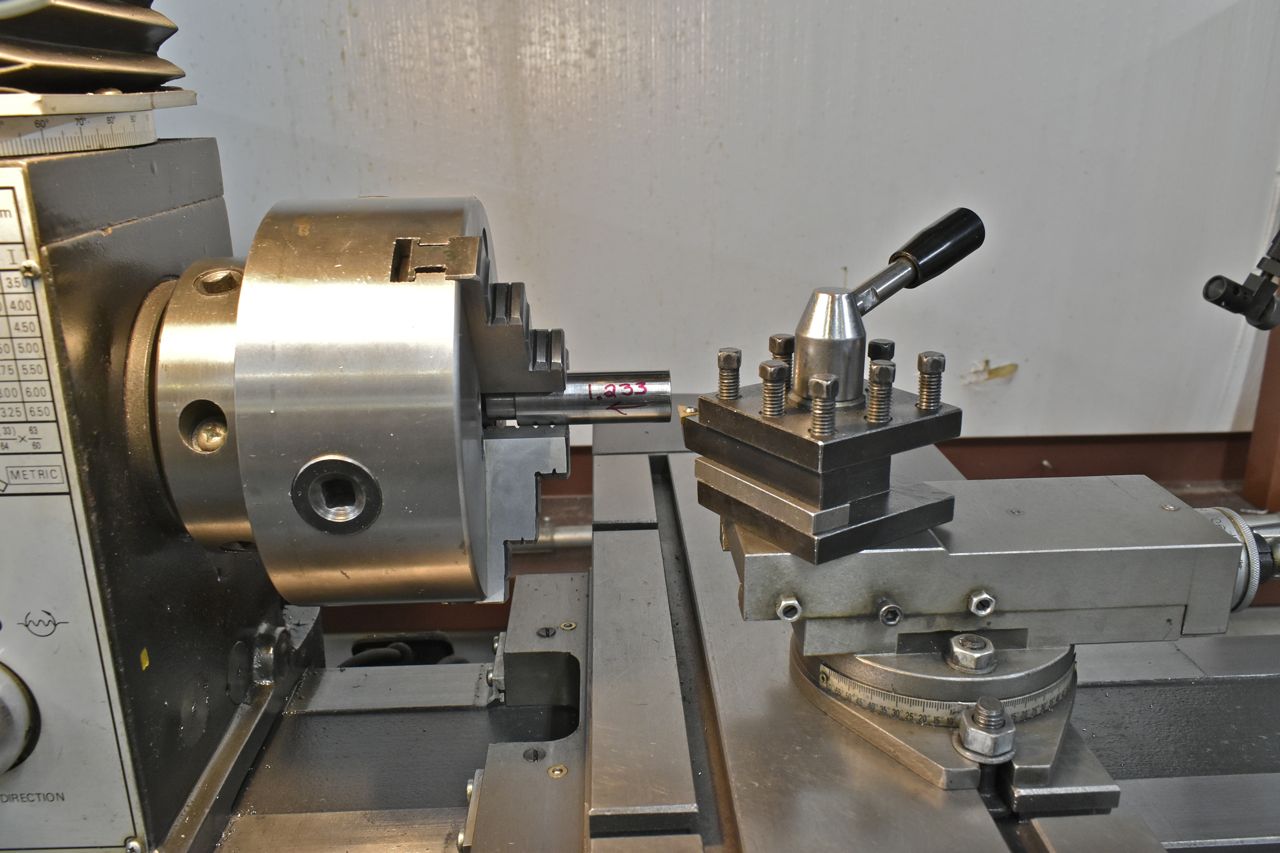

Starting on the idler.

Same process as the tension pulley.