1973 Caprice - Converting GM 12 Bolt Rear Axle to a Ford 9" Axle : part 1 Intro, Bearing & Studs

2023, November 14

part 1 - part 2 - part 3 - part 4 - part 5 - part 6 - part 7 - part 8Hello,

Just thought I'd show my trails and tribulations with converting a GM 12 bolt rear axle to a Ford 9".

So my Caprice came from the factory with an Olds 12 bolt, parts are hard to come by for it and thought it would be best to convert to something with plenty of support, not to mention be able to hold up to a car that weighs ~5000 lbs and equipped with a 454 big block. The Ford 9 inch was the most cost efficient conversion.

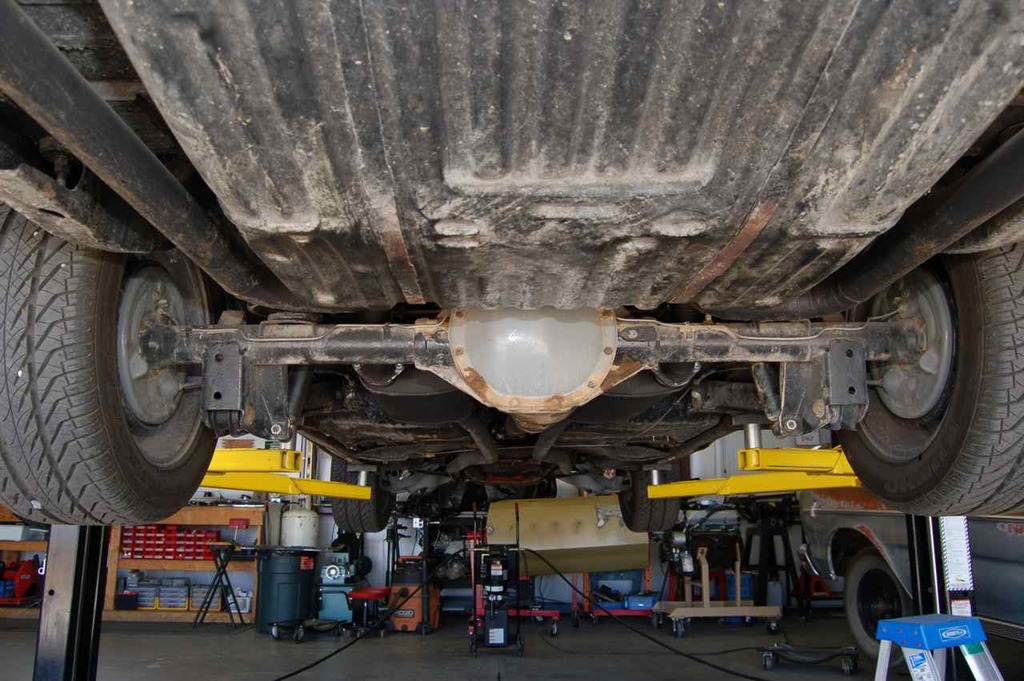

This is the original 12 bolt axle

Mind you this could also be say a later model Grand Marquis/Crown Vic application as well. As you can see it still wears its factory rear 11 x 2 drum brakes.

I had emailed several companies that manufacture rear axle and only Moser Engineering really could make the axle to fit the car without having to use the brackets on my axle (they make their own) and also make the Ford 9" to accommodate 94-96 Impala SS/9C1 Caprice rear disc factory brakes.

Another critical area is I had custom alloy wheels made to fit exactly (are wide) and any deviation inboard or outboard in axle width would cause tyre rubbing under max suspension travel. So I had to measure the difference in Impala SS rotor thickness and OEM '73 Chevy rear drums and give Moser the flange to flange distance and as an extra verification WMS-WMS distance (WMS = wheel mounting surface).

And here's the direct fit Ford 9"

It's a good idea to double check angles and measurements where you can.

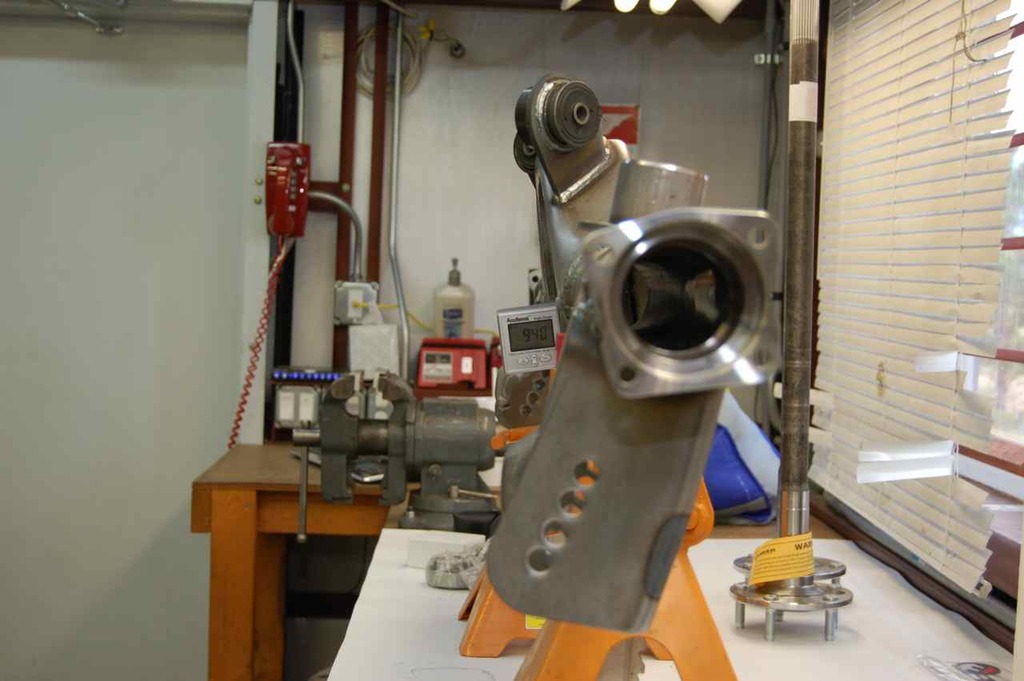

Another area of concern were the axle shaft spacing of the bearing. Moser had shipped spacers in case I needed them for the GM later year disc brakes from the Impala SS. Problem is with a Ford 9" installing the bearing is a one time deal and pressing it off often damages them.

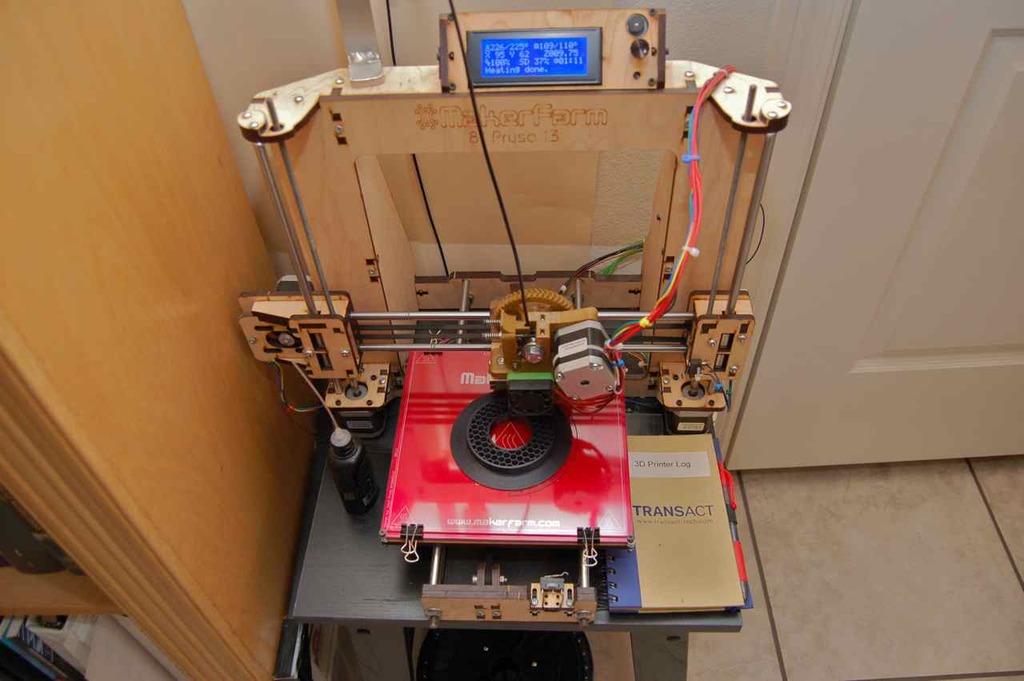

So I needed a faux bearing that could easily slide on and off to measure clearances. With that I modeled the Ford bearing in 3D CAD and printed two out on a little 3 D printer.

The plastic bearing critical dimension were within a few thousands of the real bearing. I decreased the OD and increased the ID for an easier hand fitment.

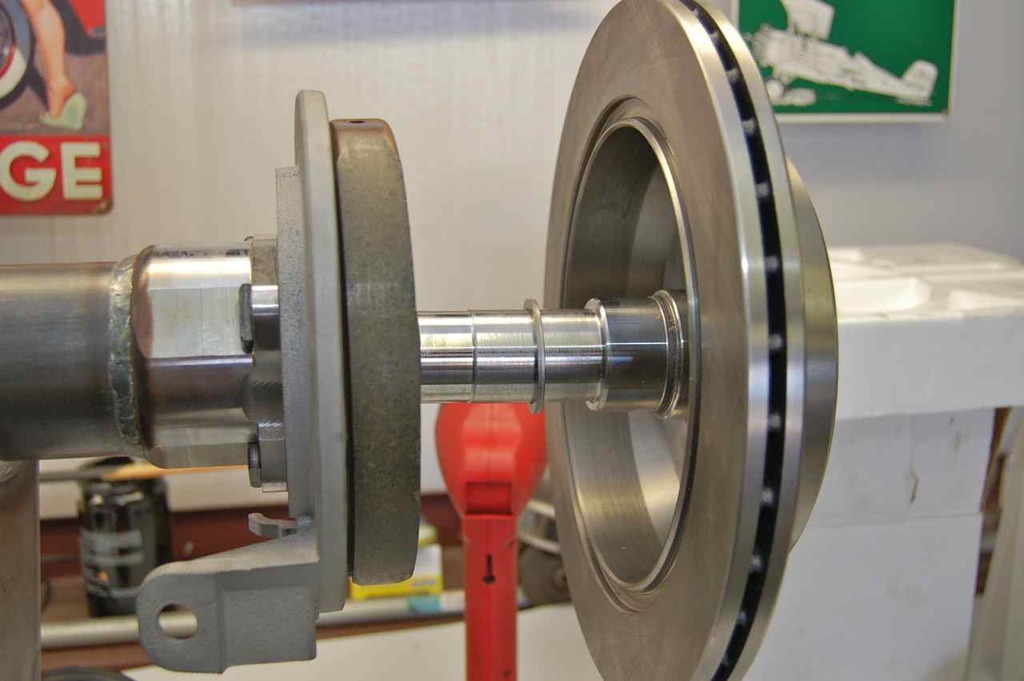

Backing plate installed. These rear disc brakes from the '94-96 Impala SS are similar to the Panther Chassis rear disc brakes in that the parking brake is in the hat of the rotor and uses a shoe.

This is the little spacer that does need to be used. It's easy to check proper distances now with the plastic mock bearing.

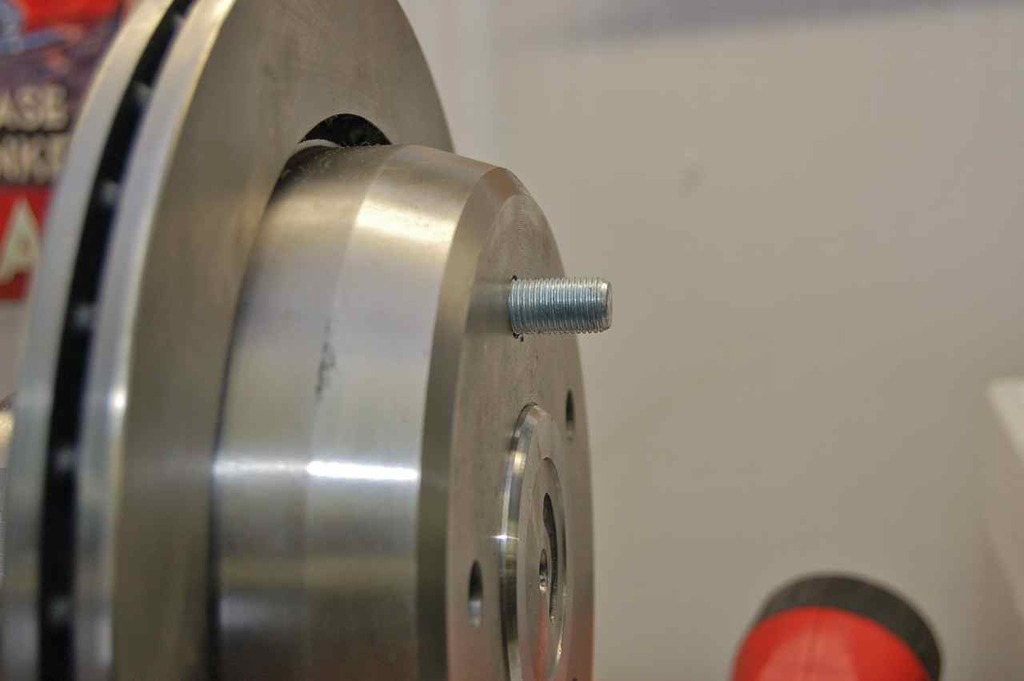

Although my other problem were the lug studs provided with the 31 spline Moser axles. Whilst they are 1/2-20 at the specified length, there is a shoulder that is wider than 0.5 " and the rotors will not sit all the way on the axle flange.

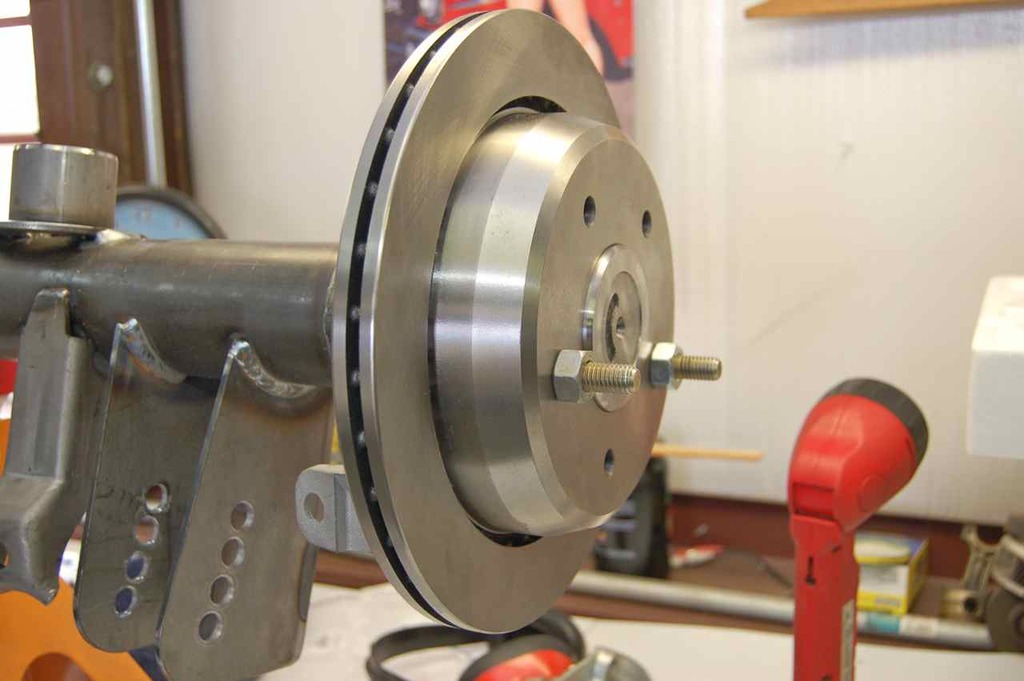

So as a temporary measure I pressed out all the supplied studs and used bolts and nuts to hold the rotors on. Then checked WMS to WMS surface and Moser was bang on with the measurements I supplied.

As you can see the supplied wheel stud shoulders will not fit through the rotor.

Ended up downloading the Dorman Wheel Stud Catalogue and tried the only feasible candidate, but it was too short.

With the alloy wheels there was only about 1/4" of thread protruding. Not enough to feel comfortable with.

I ended up turning down the shoulder on all 10 studs.

Now they fit nicely.

I intend on using a spare third member housing from a galaxie parts car to save money on one less thing to buy for the conversion. I did buy a brand new 3.25:1 gear set and Eaton True Trac differential for both wheel lock up under moderate acceleration and have it act as an open diff under normal driving without noise or vibration.

I will then have to weld tabs on the axle for the parking brake cables and hydraulic hoses, as well as add a drain plug to the housing.

Click here to continue to part 2