1973 Caprice - Converting GM 12 Bolt Rear Axle to a Ford 9" Axle : part 3 TH-400 Teardown

2023, November 14

part 1 - part 2 - part 3 - part 4 - part 5 - part 6 - part 7 - part 8Hello again,

Just a little followup. Progress has been painfully slow through this uncharted territory. I did find out why the last posts picture showing the transmission cross member was so massive. It would appear GM cheapened out and used plain mild steel. Hence the poor mechanical qualities and why it needed to be so thick and heavy. Plus after removing the rust I found a 1 inch crack in it from stress. This is what happens when you don't use the proper steel for the proper application.

For now since I'm upgrading this current transmission (TH400) next year to a 4L80E which is equivalent to Fords 4R100, it'll need another brace made from scratch so I'll mend this one for now.

In trying to determine the proper rear control arm length in order to bring the pinion angle back to nominal I needed adjustable controls arms to play with. In perusing a local farm store I saw these and had a light bulb moment.

Perfect for the lowers, the uppers needed one end unscrewed and a little adapter made.

Now I can install these in place of the OEM arms and adjust to experiment with the pinion angle over the range of suspension travel.

This is at normal ride height. Now the pinion angle matches the engine and trans. Now we are getting somewhere.

Moser put an assortment of holes for the lower control arm. Why? Dunno, but I played with the control arm in different locations and measured pinion angle stability.

Once I was happy, I soon realized before I set anything in stone I had better change the engine and transmission mounts first because they are pretty blasted from age and torque.

Well one thing always leads to another. Here's sir leaks a lot with no reverse when it's cold. I figured why not remove the cars Th-400 and go through that to fix its problems. It's been 25 years since I rebuilt this transmission. The leaks were so bad it was about a gallon per month.

So I was off to see what I could do to make the GM Th400 fit on the C6 adapter I made a while back.

Not to bad, pretty quick and easy actually.

Done. Cool beans it works.

Let the tear down begin.

In 25 years I probably only driven the car 20,000 or so miles, but that poor transmission looks more like 120,000 miles on it. Yes I am a bit hard on the old girl.

This was one of those cases where the gunk was doing the sealing and if I did a complete flush and fill that would have killed it off earlier.

The tedious not fun part. Cleaning everything.

For those not familiar with GM's TH-400 this is one of the key aftermarket pieces the transmission needs to be upgraded with in order to live behind a high torque big block. When I say high torque I mean around 600 ft lbs at the crank starting around 2200 RPM's. After achieving this with the engine this 5000 lb curb weight Caprice Classic was spitting out stock TH-400's. Eventually I had enough with having alleged "reputable" shops dork me around clearly not being able to build this so I bought a couple of books way back when on the TH-400 and learned how to rebuild and build a transmission for the first time. This particular transmission was out of a 1 ton box truck and it just took one full throttle run in my Caprice Classic and it blew apart. Upgrading certain parts made it last all these years. Till now.

Stripped all that US Navy gray off.

That transmission also got a little hot over the years, between heat and age I had to replace most of the plastic parts like this connector in the case. This is the forced kickdown connector as the TH-400 is electric in this respect and not cable or rod activated.

Also found a nice speedo gear calculator based on tyre size and rear end ratio for all type of older American made transmissions. I bought a new gear to bring the speedo calibration back to nominal from the rear end gear ratio change and earlier tyre size change. Plus the original gears were pretty darn brittle like all the other plastic parts.

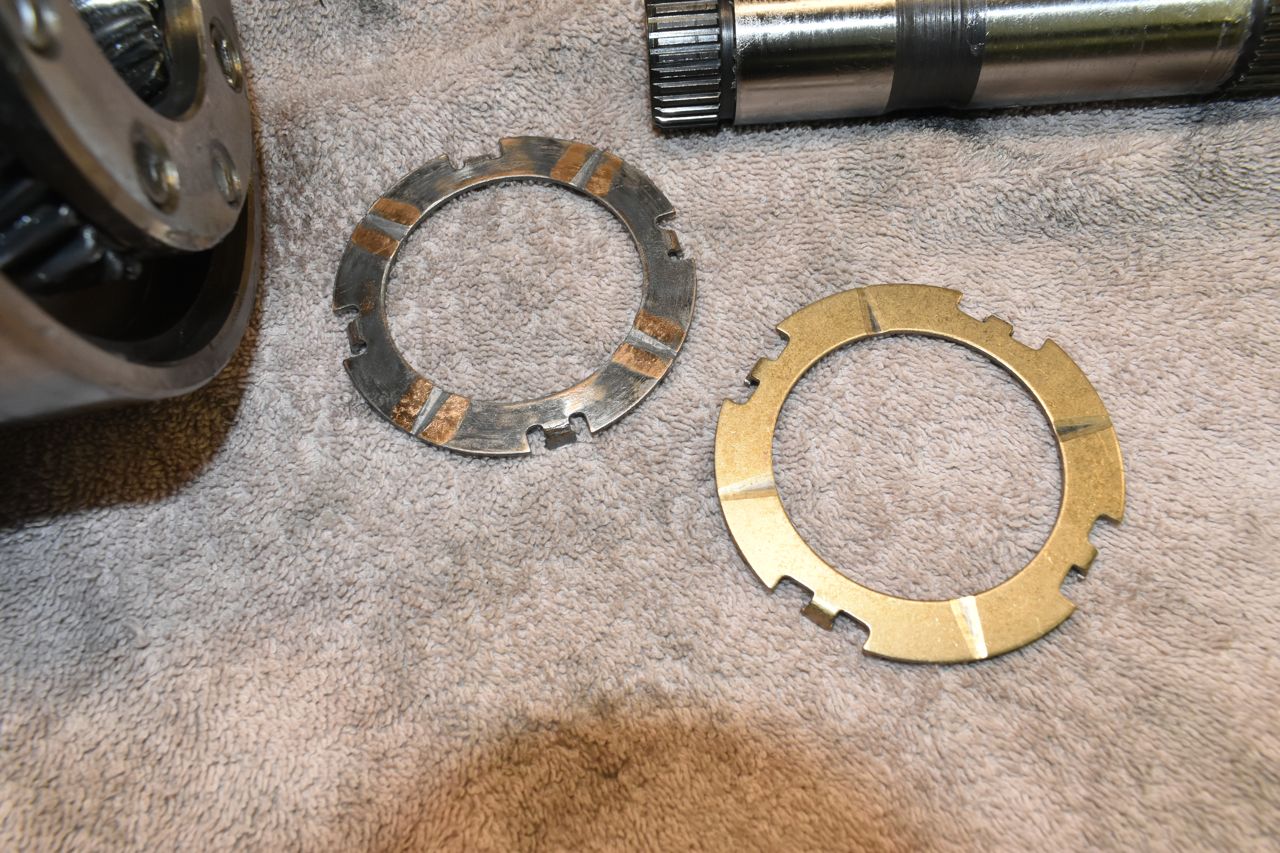

Aside from needing all new seals, gaskets and plastic pieces, these were the other parts that were worn down. These are the thrust washers in the planetary assemblies. There are two of these in the TH-400. Sad part is GM used torringtons for every other spot except these. Had they converted these this transmission would be fully rollerized. The reason why these wore down in such short miles on the transmission is because of the taper cut on the planetary gears which causes the gears to be either sucked together or pushed away depending on rotation. Either way, with a high torque differential caused by an engine that really puts out and a rear axle ratio of 2.73:1 coupled to a mass of 5000 lbs those washers end up getting mashed between two rotating parts of different speeds very hard. Hence the wear.