1973 Caprice - Converting GM 12 Bolt Rear Axle to a Ford 9" Axle : part 4 Custom Control Arms

2023, November 14

part 1 - part 2 - part 3 - part 4 - part 5 - part 6 - part 7 - part 8Picking up where I left off. Looking loads better.

Even though I don't plan keeping the transmission a little detailing never hurt.

Here's a little interesting comparison. A C6 and the TH-400. If anything I just want to impress the fact that even though a transmission might have low miles it's age that can cause it to fail. These seals were turning into a mix of some turning spongy and some turning hard. I found one seal that had shrunk and wasn't even contacting the bore it was in any more. As for the frictions and steels. The only frictions that had wear were the direct clutch and intermediate clutch. They were half used up, but since I don't plan on keeping the transmission too much longer since they were still serviceable, they went back in.

Now that the transmission is done back to the engine mounts. Old one on the right, it's rebounded without the engine weight, but installed the lower portion was completely collapsed. This is the driver side where the engine torques down on it. The passenger side wasn't too bad.

However putting the new ones in turned out to be a royal pain. I had to enlist the help of a friend and both of us push, pulled and yanked on that 900 pound engine for 45 minutes to finally get it to sit in the new mounts. Time for that cast iron monster to go on a diet.

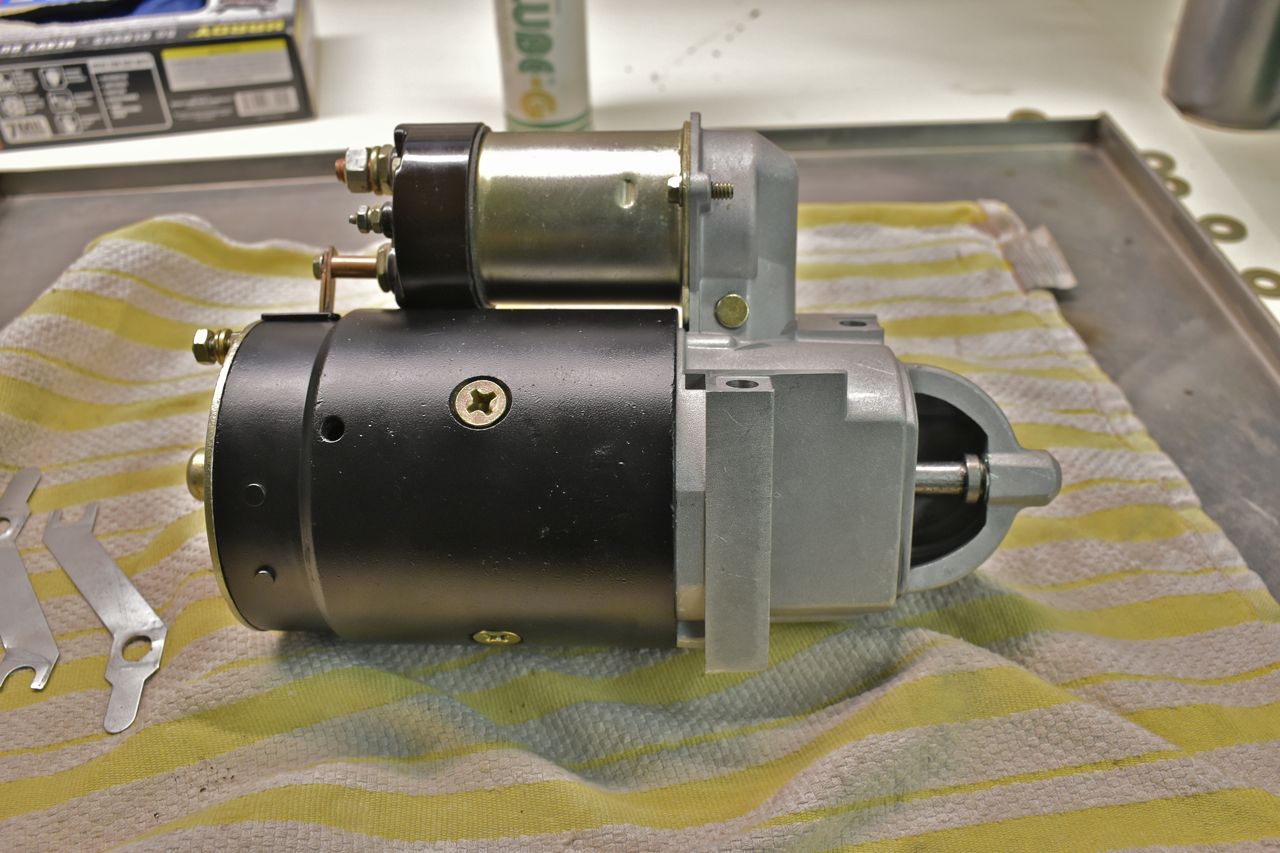

Another side track was the starter, this is 20+ years old and no better time to go through it as well.

The internal parts were still in really good condition. I just cleaned out the carbon dust from the brushes and the grease that was starting to harden. Put fresh synthetic grease in it and spruced it up a little and this should outlast me.

Ready to go.

Now that the transmission is back in with all new mounts, back to the axle.

Keeping the pinion angle at nominal I centred the axle with the temporary adjust able arms.

After that I measured the temporary adjustable tractor arms and made temporary fixed length lower control arms from some old galaxie spare rear arms. Now I cut them, jigged them the exact same length and welded back together. The upper mounts on the axle needed to be moved slightly in order to mitigate bind using the OEM rubber mounts. So I carefully removed those and the spring perches since they were practically off in a different quadrant by now.

Next up is make the final upper adjustable control arms for my baby.

Due to the fine nature of crappy aftermarket parts, I've learned my lesson and now order more than one item because sadly I'm guaranteed to find substandard parts. Buying the OEM mounts for the heavy Chevy proved to be no exception. Some of these mounts are so horribly made if you used them it would throw the rear end alignment off.

Stick with Moog parts, those were the best.

The beginnings of the new adjustable upper control arms. The adjuster bolt is grade 8 and all steel used is 3/4 hard 4130 Chromoly certified aircraft steel. None of this mild steel nonsense for critical applications. Even the TIG filler rod is 4130 160,000 ksi as welded tensile strength.

One of my car chums is a big Oldsmobile fan and he mentioned some of his Oldsmobile acquaintances bought tubular control arms and are experiencing cracking from early metal fatigue. Car companies spend oodles on R&D and testing before it goes into production small companies do not. Some of these aftermarket parts make me cringe. You have be so careful and so vigilant nowadays with small places making safety critical components like suspension and brake parts for aftermarket. Some of them have no concept of metallurgy and you are literally taking your own life and others lives in your own hands using these parts as having a catastrophic structural failure at high speed can be disastrous in more ways than one.

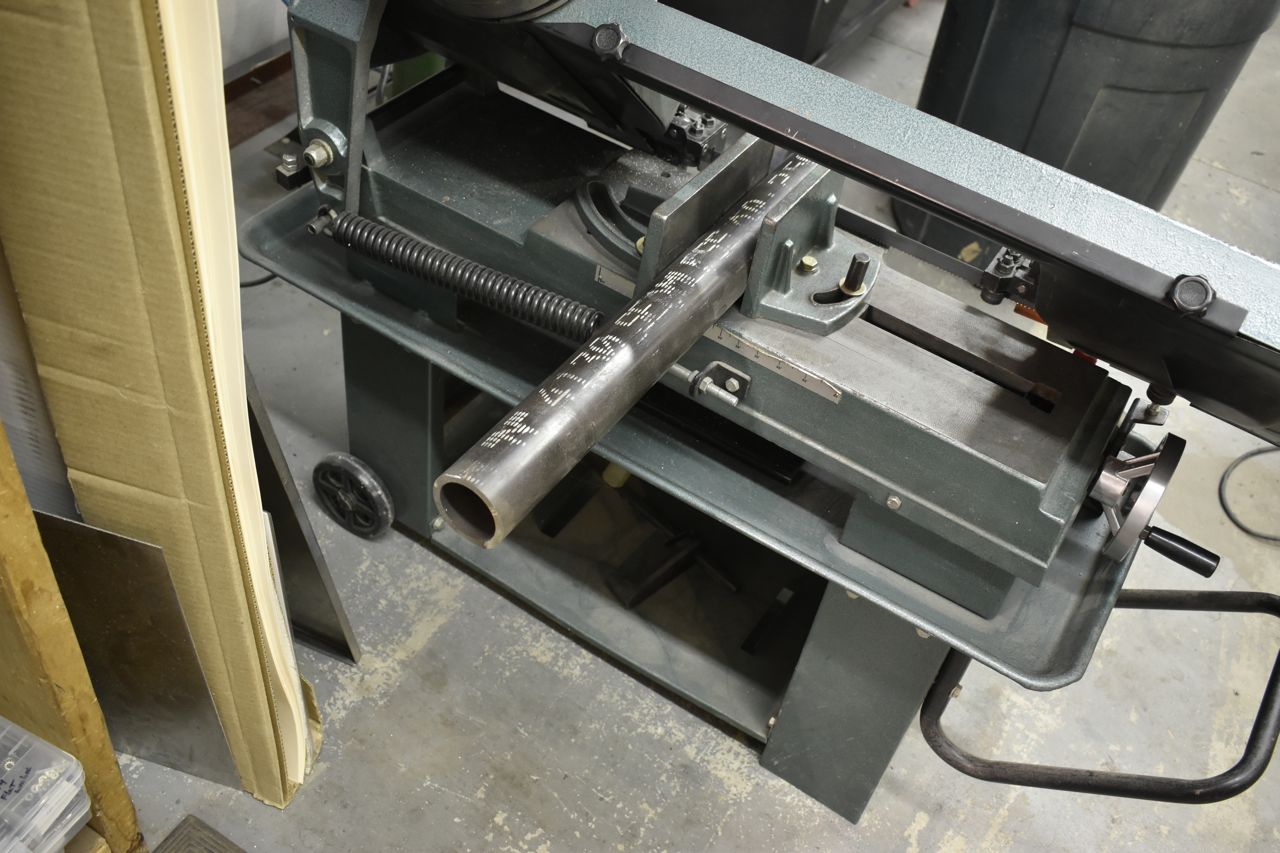

My bushing housings start off from a tube.

Then it's inside bored to match the OEM GM bushing, including the slight step.

The makings of the other cupped end.

The 4130 filler rods flows nicely.

Now it's looking like an upper control arm.