1968 Ford LTD Rat Rod Resurrection : part 5 Bendix Booster Overhaul

2023, November 14

part 1 - part 2 - part 3 - part 4 - part 5 - part 6 - part 7To take apart the Bendix, the two halves need to twist to unlock. Sometimes they are crimped over which could make it a pain to separate. But also the Bendix has a big return spring that needs to be contained when assembling/disassembling. So you need to grip both halves, exert a substantial torque and keep it compressed all the while. But first you need to remove the push rod from the back.

The only way to properly remove the push rod is to slowly advance a pulling pressure till it pops off. Remember this is in fragile bakelite plastic and using hammers or other impact means will break the bakelite. So here's a cheap as chips removal tool. Actually calling it a tool is a bit of stretch but you get the idea.

Complex as a bolt with a couple of washers welded at the edges and a bolt through them and the push rod hole.

Then just a hollow piece of pipe, add washers and nut and draw down the nut. This pulls up on the push rod, it'll pop out without harm.

Push rod. It's just held in with a ball and socket affair.

Now to hold the bottom piece and make something that I can spin the top. I just cobbled together some scrap pieces for....

The bottom is wedged between the beams so it can't spin and light pressure from the press keeps the spring at bay and helps reduce friction of both case tabs rubbing on each other. Then just twist. Use some lube oil around the seam/rubber gasket too to help spin it.

Then release the press carefully, check out the crazy spring. Again the Midland Ross booster uses no spring and just a band holds the case halves together. Easy peasy that one is.

Remove the master cylinder push rod and outer seal.

Carefully lift up the rubber diaphragm around the edges.

And lift the entire guts out the back half shell.

So it looks like they welded in longer carriage bolts then sealed the weld with some kind of sealer then coated the whole thing. Good grief.... Also there is a rear seal pressed in the case.

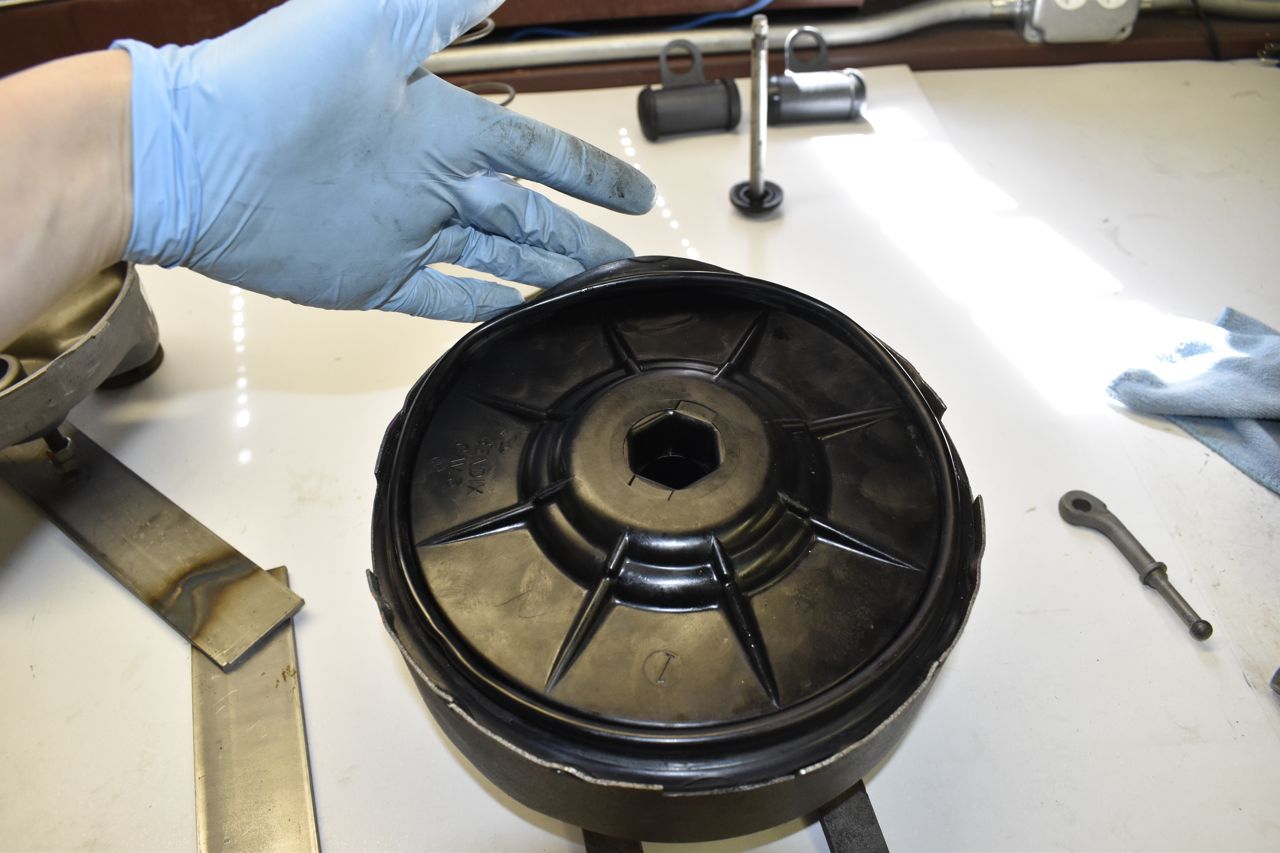

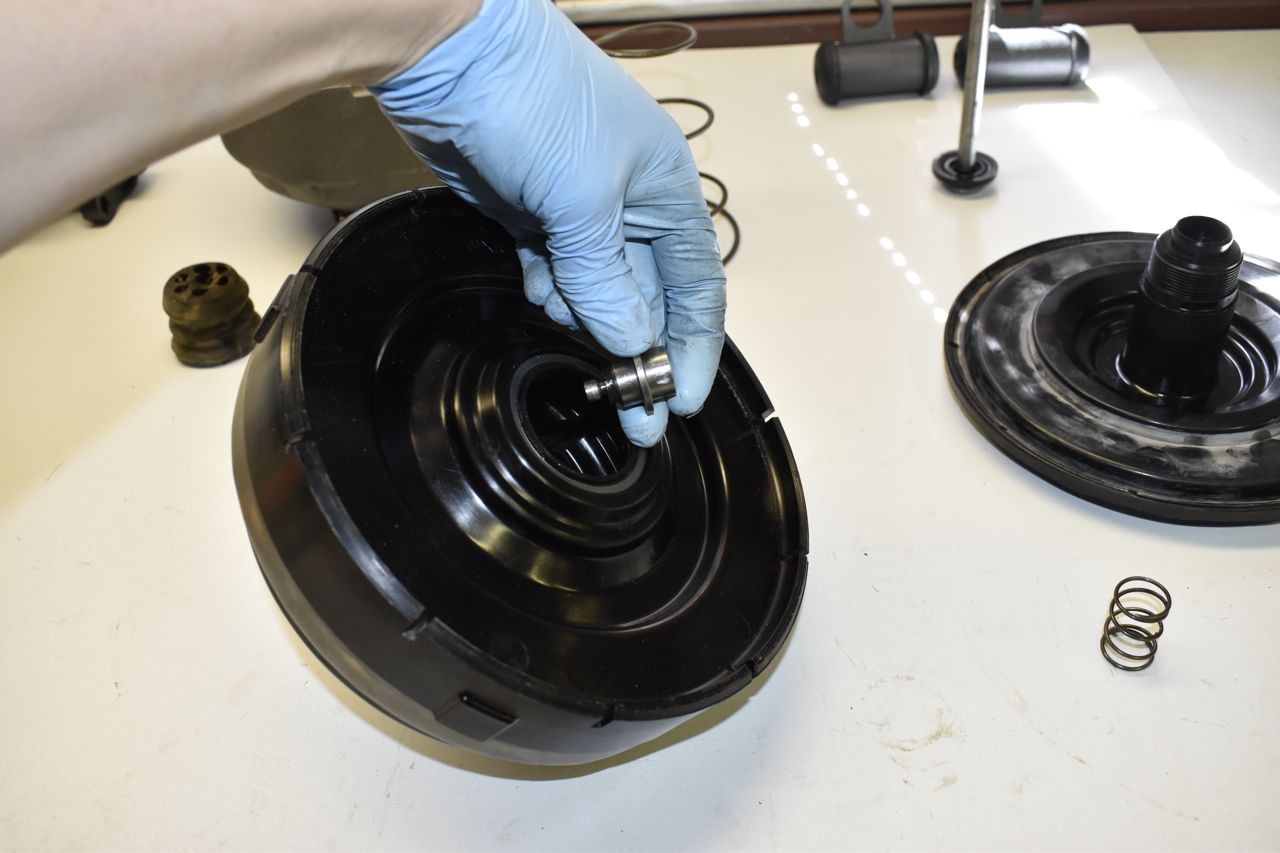

There are two halves to the dual booster guts, I made a quick and dirty tool (ground down nut sandwiched between two other nuts on a bolt) to insert into the hexagon hole. Then hold onto rear half and twist the bolt. The whole thing will unscrew.

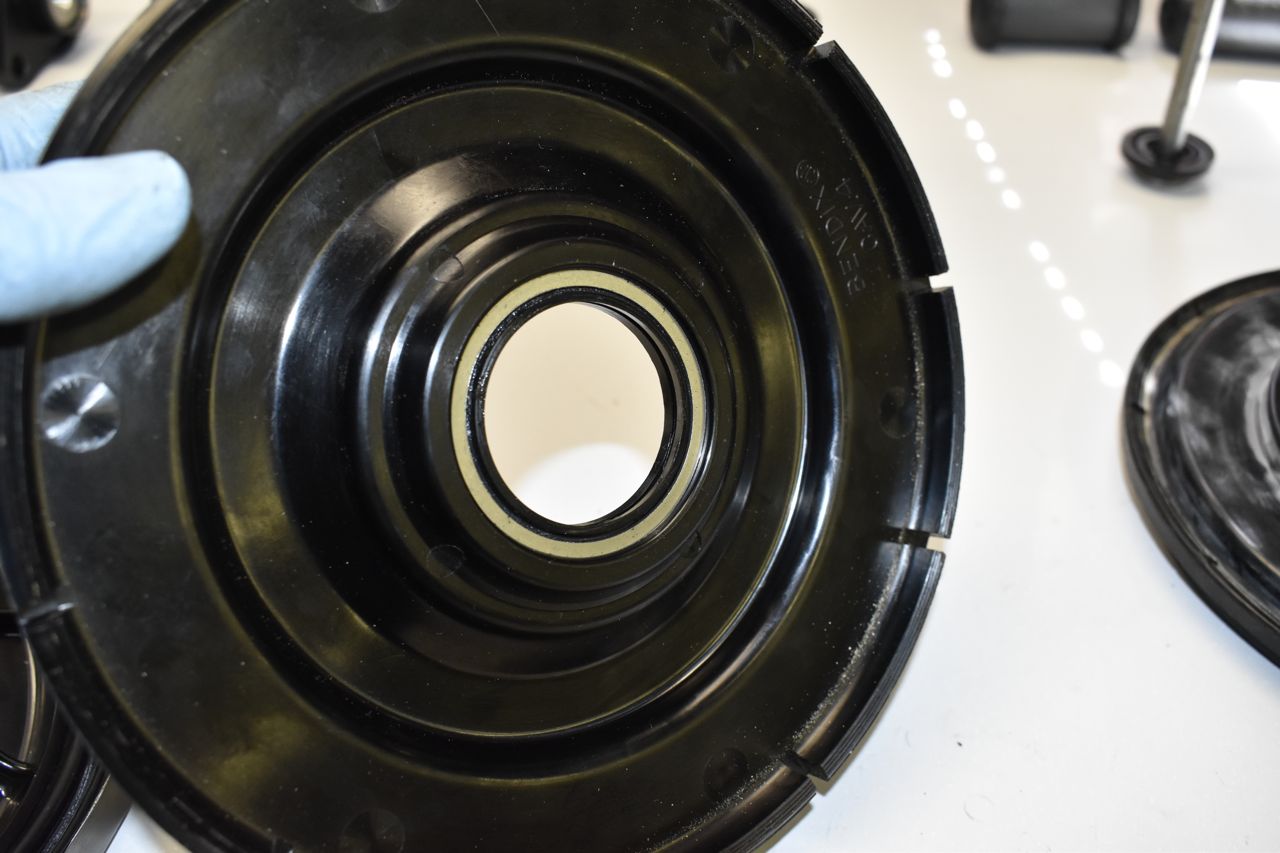

You can see seal on the left half and rubber seal on the right half. So far everything rubber looks to be replaced.

This is the rubber seat that the master cylinder push rod sits on and is part of the reaction disc and valve (boost metering).

Pulling the diaphragms off and inspecting. So far all looks good.

The reaction valve.

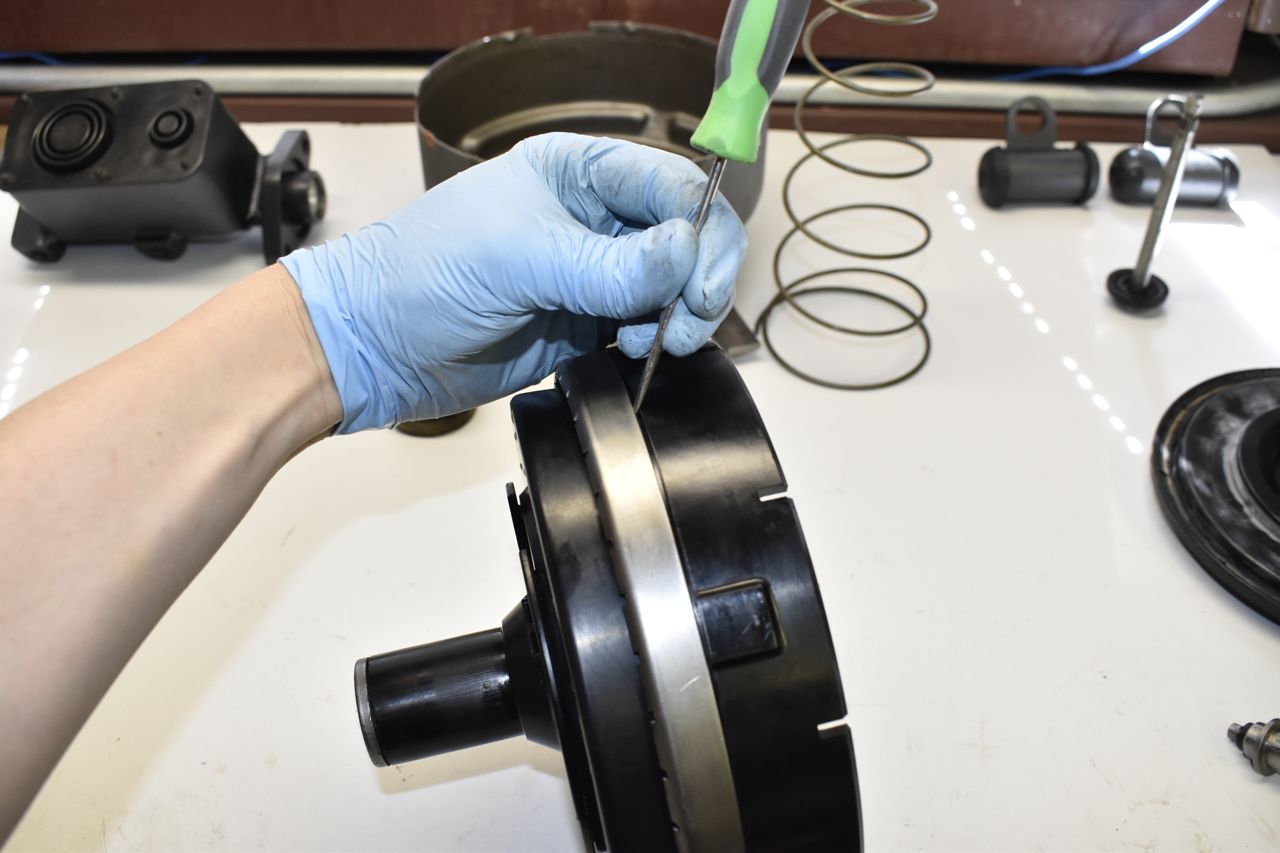

Carefully work the rear diaphragm retainer off. just be careful to not injure the rubber. Take your time.

Now pull off the rear portion from the centre portion.

This rubber seal looks like A1 replaced it.

Another rubber seal in the rear section.