1968 Ford AM-FM Stereo Overhaul : 06 Repair - IF Transformer Re-solder (AM Band Fix)

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18Radio Overhaul - Repair page 3

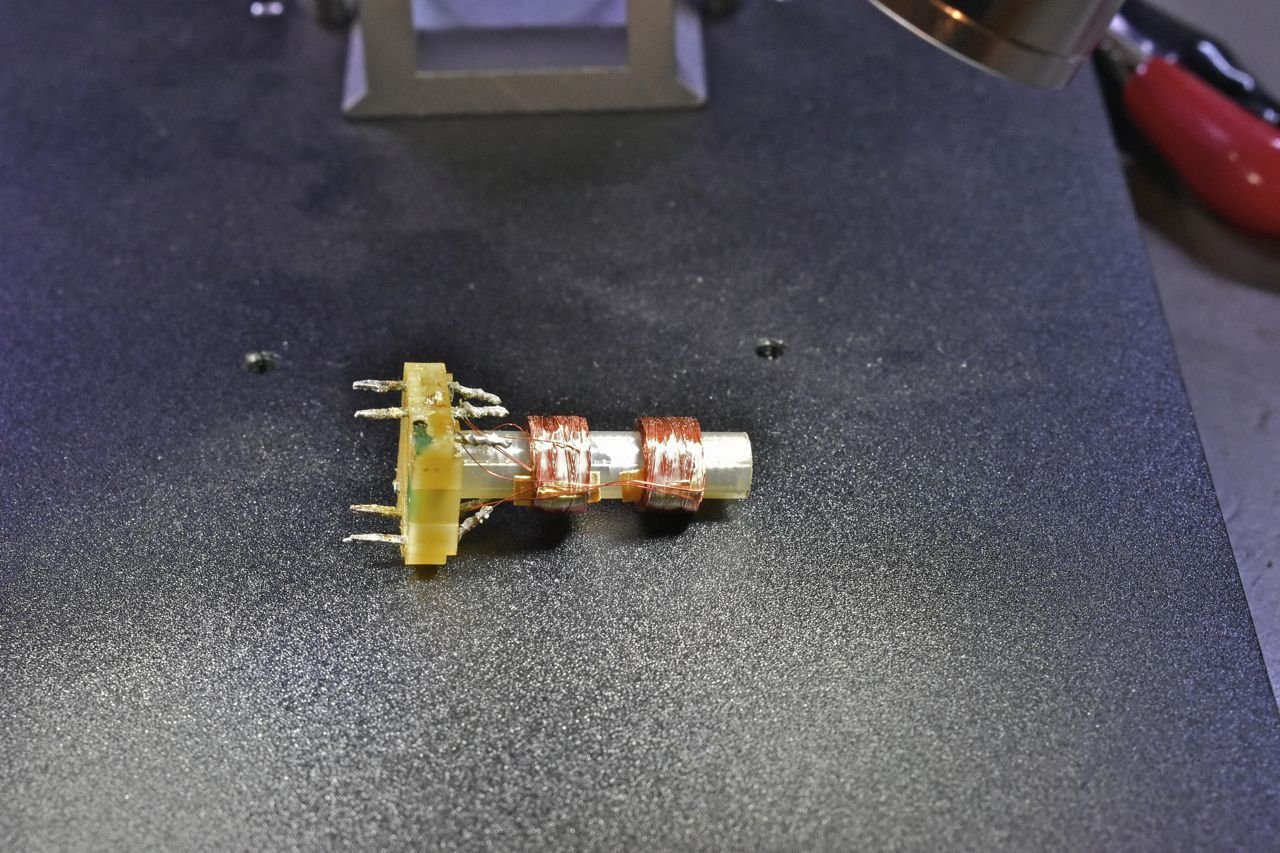

This is the actual IF transformer assembly. Here you can see the primary and secondary windings separated by an air gap. They are not wound atop one another like you would probably see in a power transformer or audio transformer. In the plastic base are the small mica tubular capacitors as shown on the schematic. Together with the inductance from the windings and the capacitance this forms a tuned circuit which peaks at 262.5 kHz when adjusted. What you can't also see are two ferrite tuning slugs, one under each coil. They screw up and down the centre tube changing the resonant frequency. These are the slugs you adjust when electrically aligning the radio.

Back to the problem at hand. The terminals look extremely corroded. Let's have a closer look.

Well, there's the problem. However this begs the question why did the solder and copper wire oxidize so badly and only at the terminal.

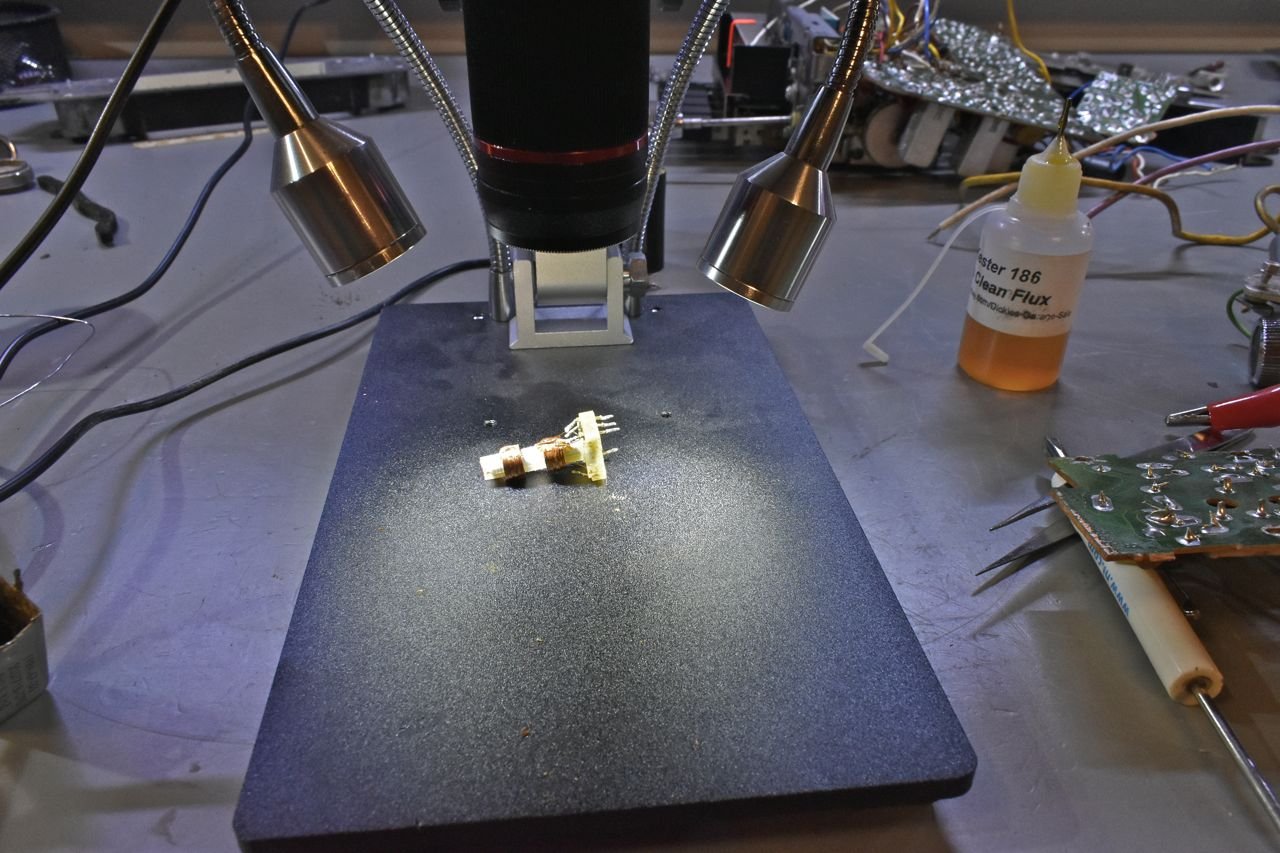

Fortunately there is enough slack in the copper windings to reattach. However all that corrosion must be carefully and meticulously removed first. I can't use chemicals without damaging the rest of the assembly. It was a painfully tedious slow scraping to remove as much corrosion as I could.

What happened here is actually pretty simple. Someone on the assembly line making these used a solder with an acid core base and not rosin core. The acid will slowly oxidize the joint over time but look just fine right after soldering initially.

And here it is repaired.

You get the idea. I redid all the connections in this transformer and removed as much of the corrosion as I could. I use 3% rosin core solder and sometimes use no clean rosin flux liquid on stubborn areas. All these are safe long term on connections.

There's a high probability that even my other parts radio has the same problem so trying to find a usable part may prove to be very difficult if not impossible. So sometimes you have to make difficult repairs.

Now even though the 1st IF transformer was working I was worried it might have the same problem only to rear its ugly head later.

Sooooooooooo

I pulled that off the AM board and pulled it out of the can.

This is what I've found. Factory fresh 50+ year old solder that looks like it was just soldered. This person on this assembly line used the correct rosin core flux solder. No worries here.

This will fix the AM band.

Click here to continue to part 7