1968 Ford XL Repairing Whilst Keeping It Roadworthy : 03 Air Conditioner Idler Pulley

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74Air Con Pulleys

And it begins. This wasn't on my already lengthy list of things I found wrong, but I was just barbequing some steaks on the grill and since the grill is right by the garage I was looking over the engine compartment on the XL whilst waiting to flip the steaks. It was then I noticed the tensioner pulley assembly was replaced but it still was running an old idler pulley. That sent shivers down my spine. So next day I removed both the tensioner and the idler and sure enough the idler was on borrowed time. Whilst it spun, you could hear and feel the ball bearings and races were galled and there was just no lubricant in it. This was a few months from failure, especially a hot summer month with the A/C going.

With that I decided to take my spare idler pulley apart and see what I could do as it's different than the '65/'66 A/C pulleys for FE.

This is the idler pulley and bracket off the '68 with FE. Ford really started to cheapen out even by '68. The bases are no longer nice cast iron machined bases, it's just a soft thick chunk of steel that's blanked, punched and stamped. However, Ford started using actual common Imperial/English size bearings and not the weirdo half metric half Imperial/English integrated bearings as on the '65/'66. On the '68 you can just pop the cover on the pulley off, remove the snap ring and press off the pulley, press out the old bearing and reassemble.

However I like my solution to simply unbolt the pulley from the bracket especially since the bracket is a bear to remove from the car. The '68 front dress is really cramped compared to the '65/'66.

So this is kind of cheesy. The bracket is so soft they had to spline the shaft stub then stake it in to keep it fixed in place.

deja vu.

I will not repeat the machining process to make your own pulley shafts as I have done in the past, for those interested please see here: 1965-1966 Ford A/C Idler and Tension Pulleys Rebuild for FE

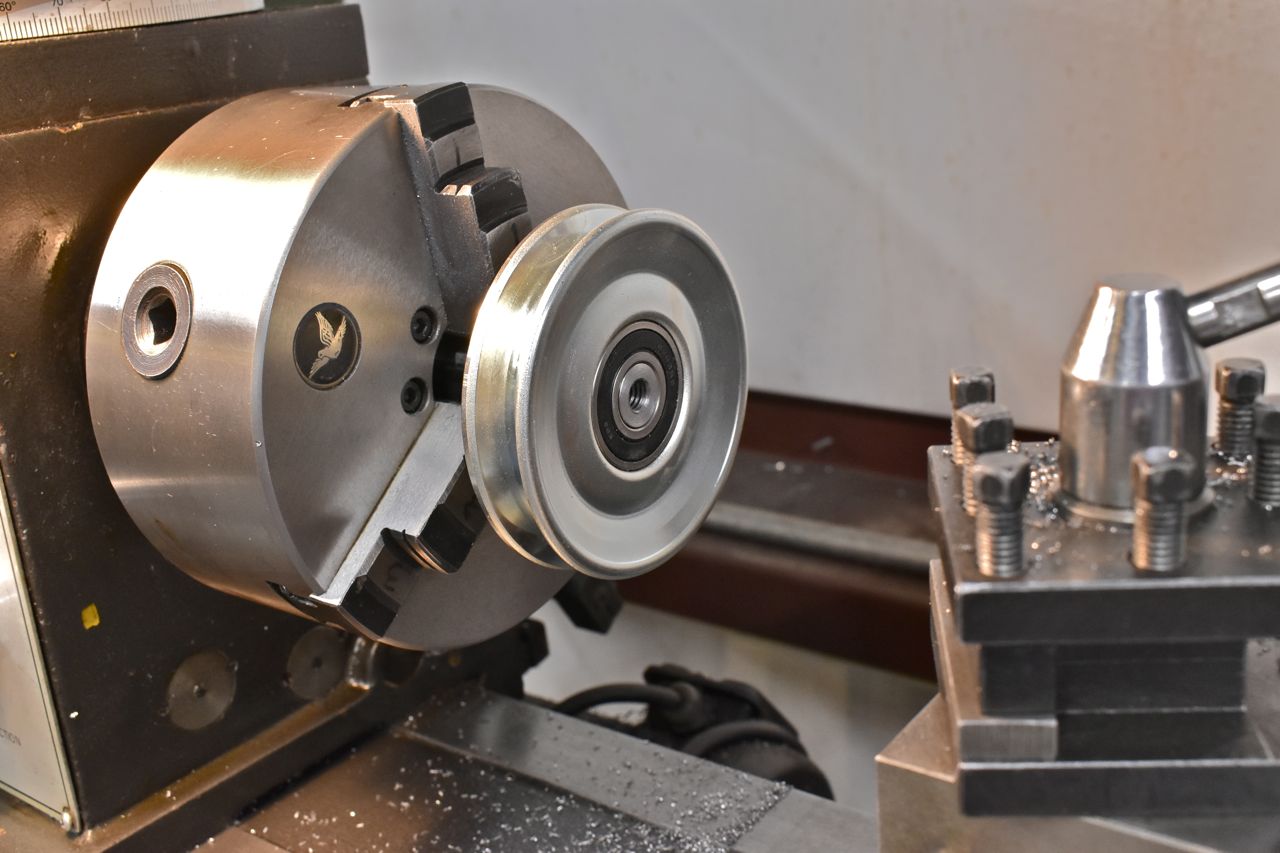

All that's left is cut down the other half of the shaft.

I don't have the ability to spline (broach), instead I oversized about 0.003" for a tight press fit. 0.003" sounds like a lot but the splines will mush over and take up some of that space as well.

It was a nice tight press.

Then I staked the back side. I really had to wallop that shaft steel to get it to spread.

That's the goal. Now they are really easy to service.

These are really hard to get to sit flat as the stampings are by no means a machined surface.