1968 Ford XL Repairing Whilst Keeping It Roadworthy : 15 Carburetor

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74Same thing with the accelerator pump. I like the small bleed off hole at the top, any liquid fuel that turns into a gas bubbles back out into the main bowl and allows liquid to enter without forcing fuel out the accelerator pump jets.

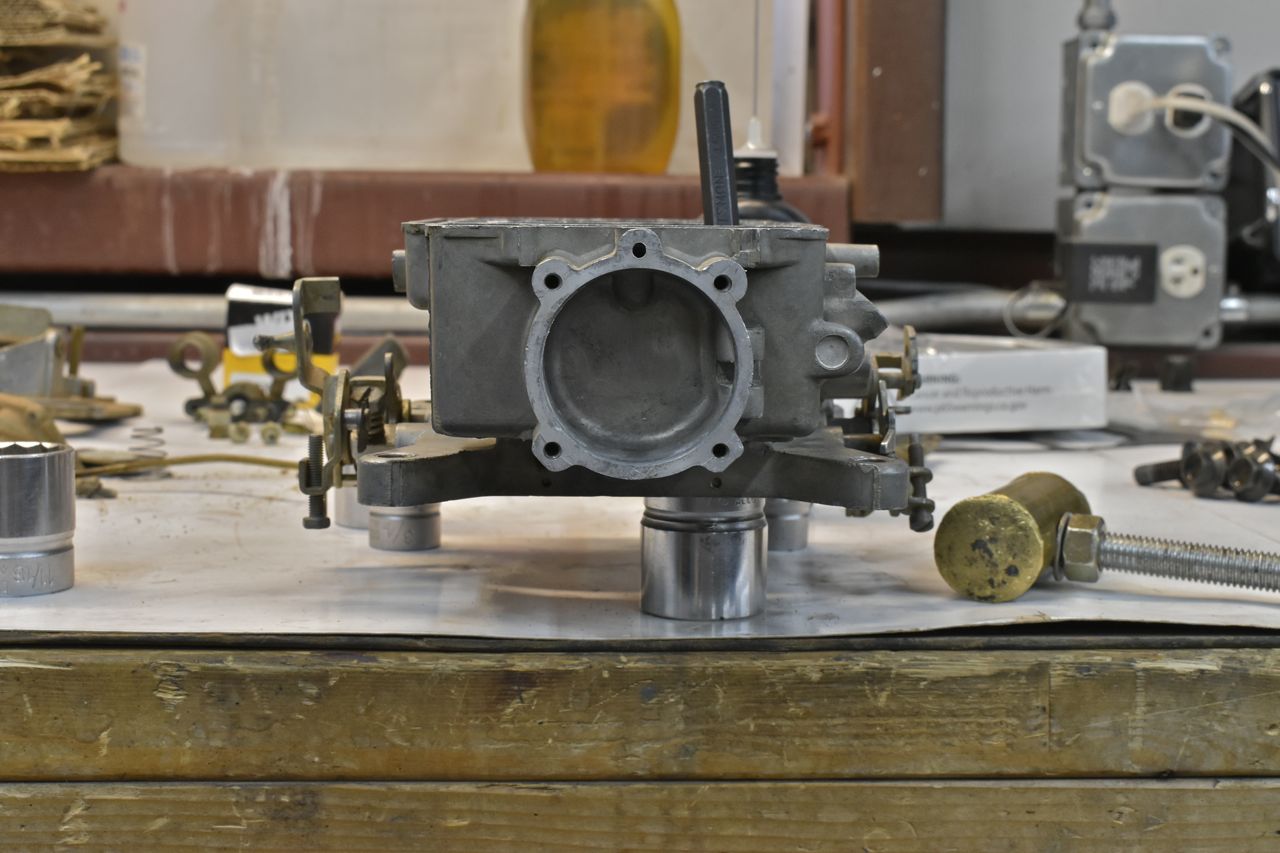

To peen the screws in the throttle blades I supported the heads of the screws with a socket.

Like so

Then just peened the edge of the screw so it can't unscrew and fall into the engine.

New power valve in the kit on the right.

Installed.

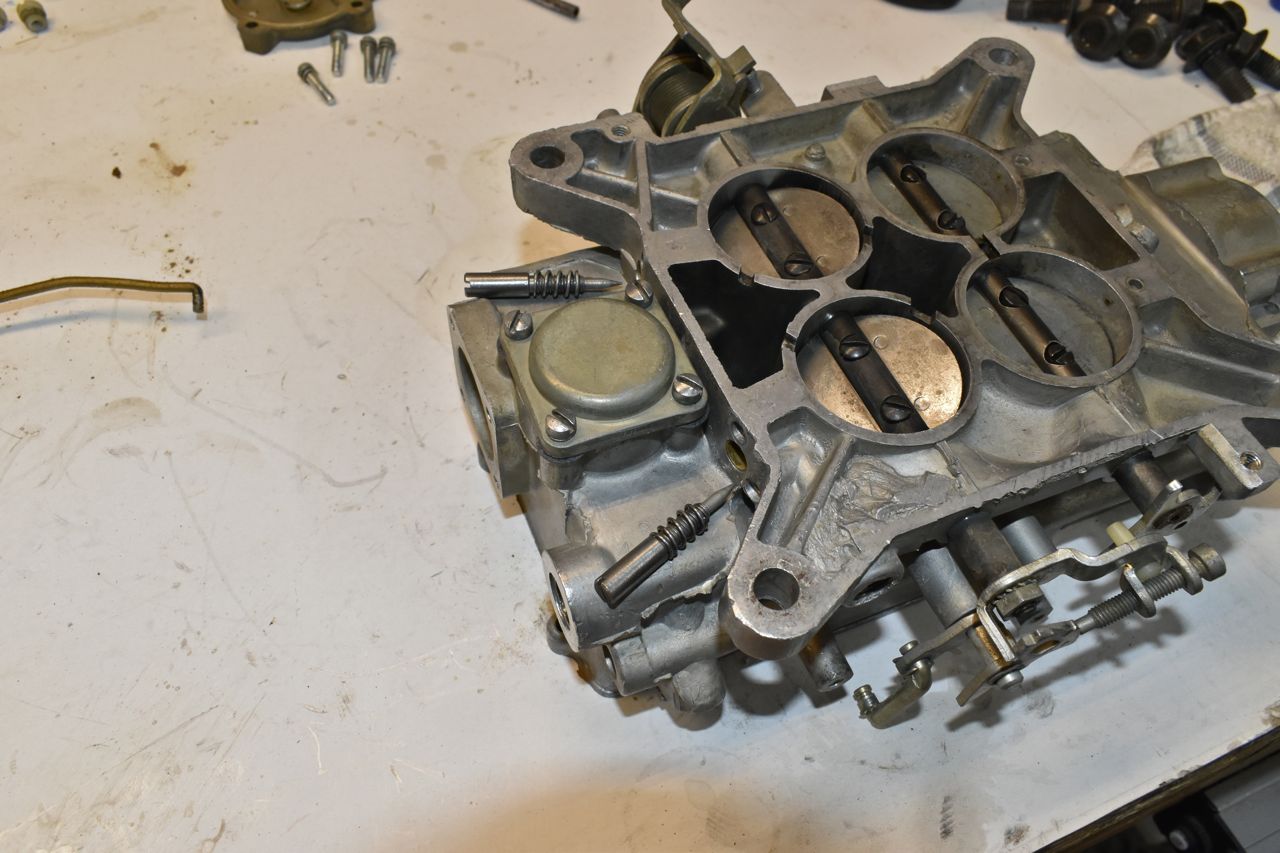

The idle mixture screws cleaned.

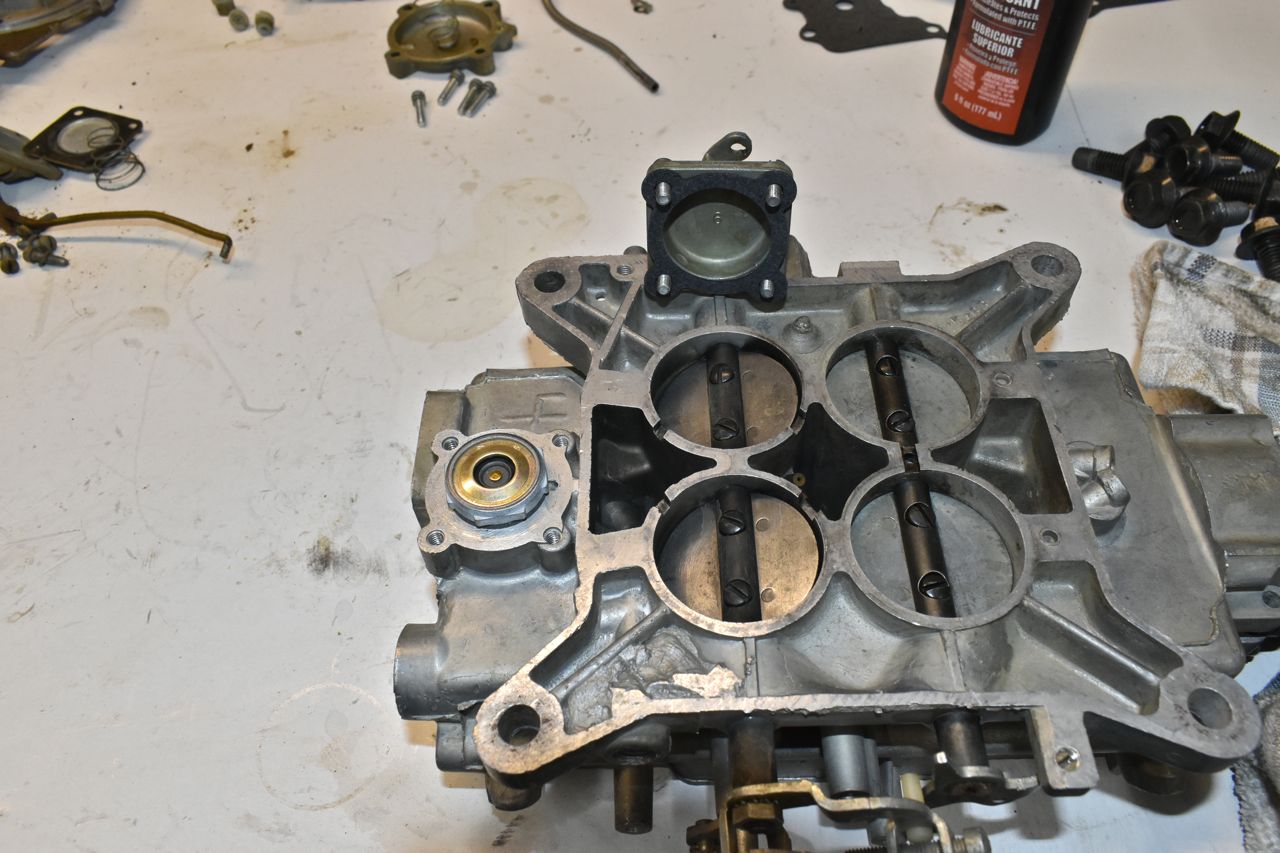

The idle mixture screws were lightly seated and backed off 1-1/2 turns.

New accelerator pump parts.

Accelerator pump finished.

This carb was rebuilt just several years ago and you can see what the ethanol did to the rubber parts. When that diaphragm is compromised fuel can leak right atop the engine and it doesn't take much imagination what can happen with fuel on a hot engine.

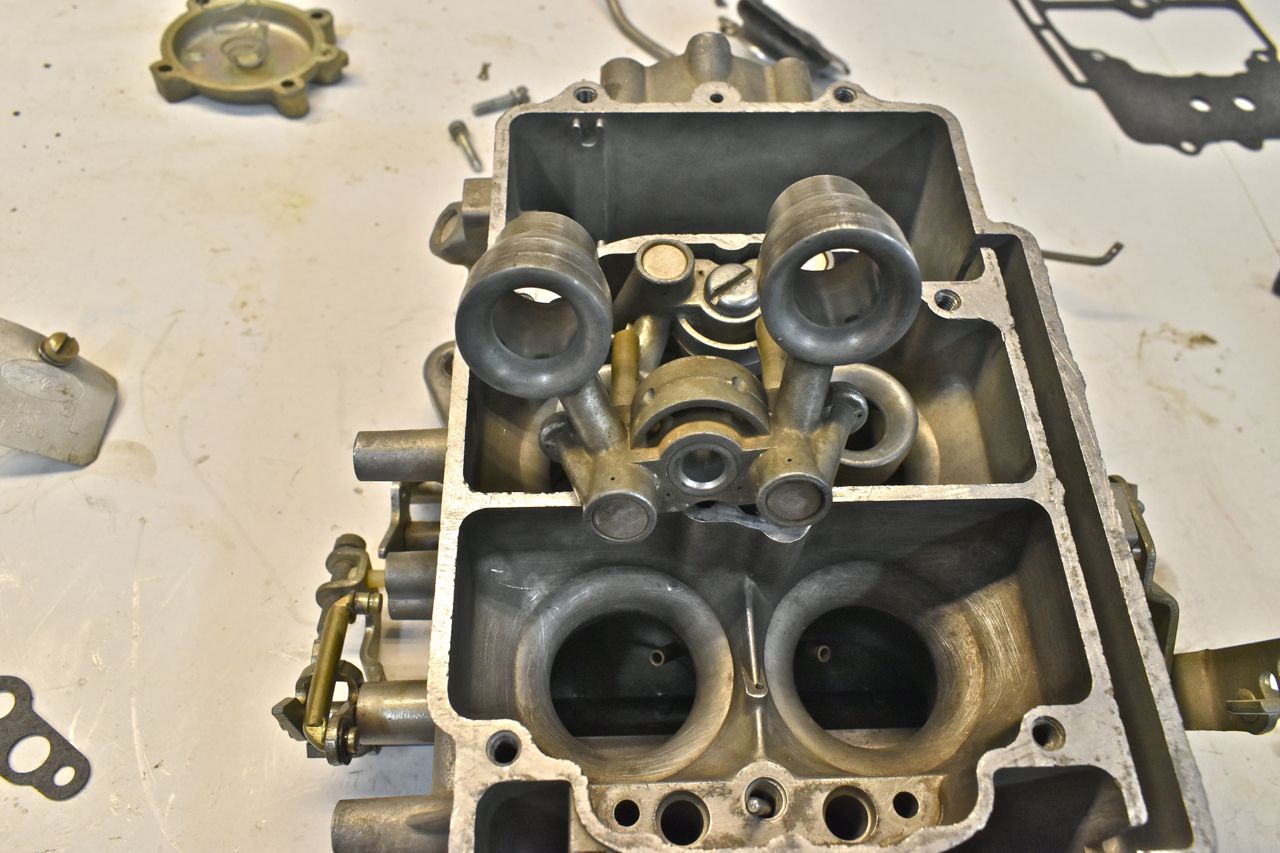

The jets are cleaned and installed.

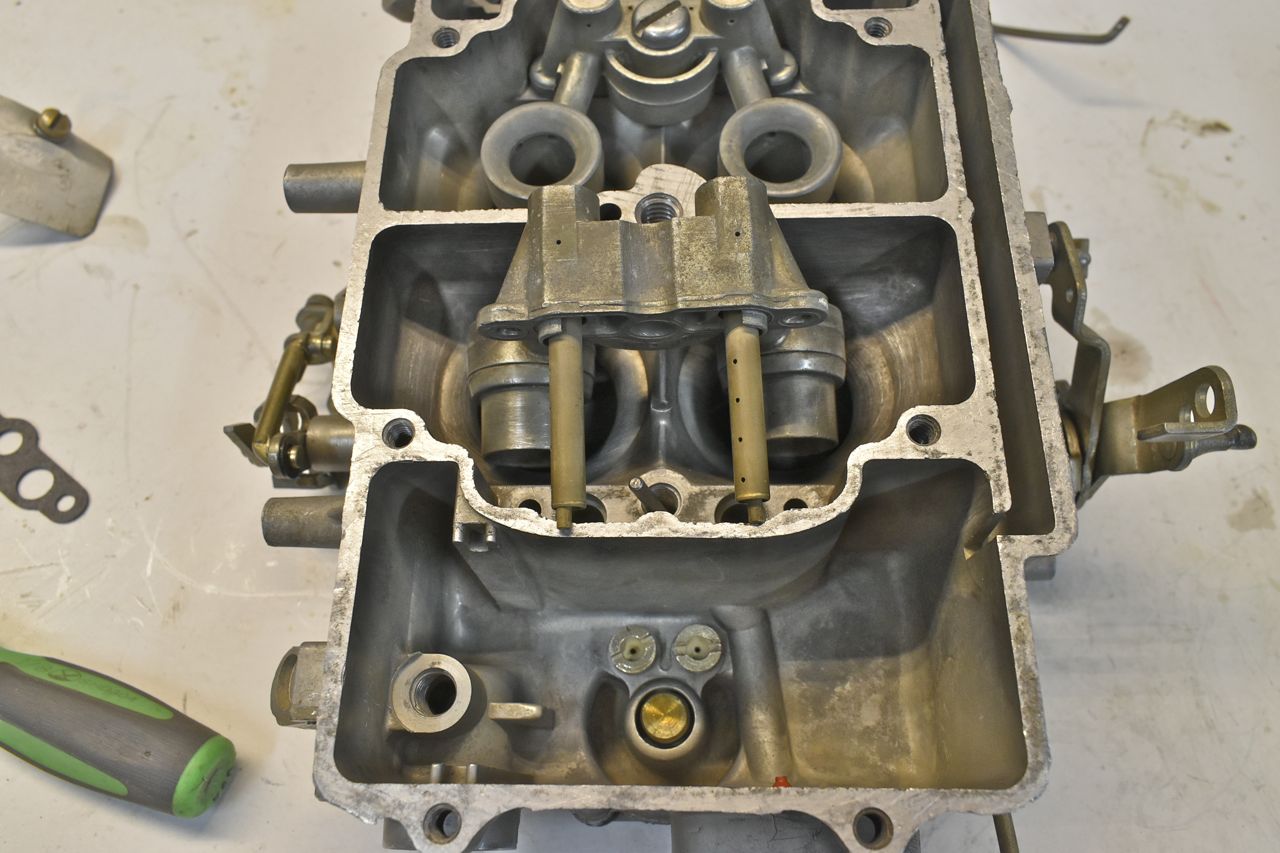

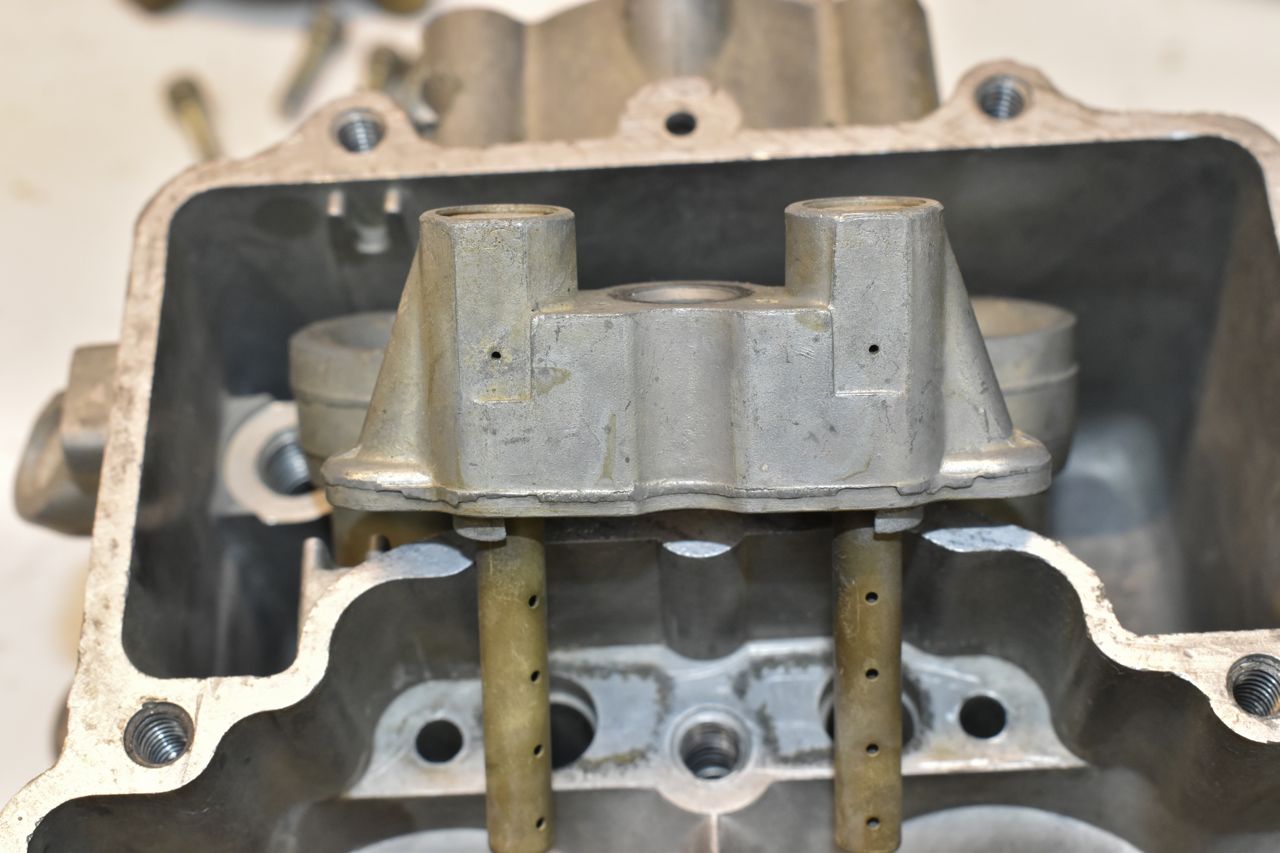

The boosters were cleaned and all air bleeds checked with a small wire for obstructions.

Taking time and inspecting every little part can save hours of aggravation later on.

Accelerator pump check ball and weight rod.

Primary booster check out.