1968 Ford XL Repairing Whilst Keeping It Roadworthy : 19 Engine Repair Misc

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74Making progress.

The choke connector arrived.

Installed and adjusted.

Electric choke arrived as well.

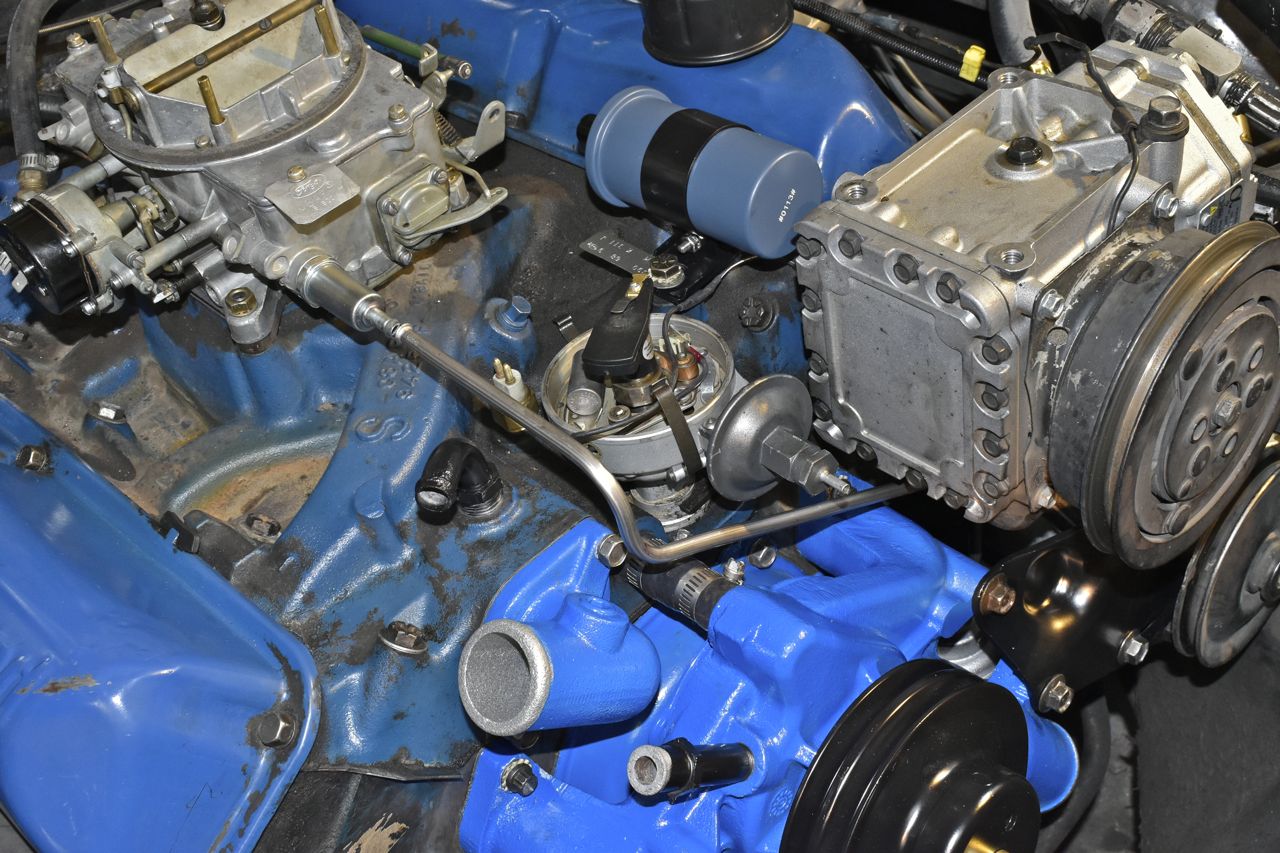

Power steering bracket.

I installed the bracket and set the power steering pump to it's minimum belt setting. I needed to do this to determine where the fuel line would route as not to hit anything. Making this fuel line was a bear but it turned out decent.

There's not much room for error with the '68 FE front dress.

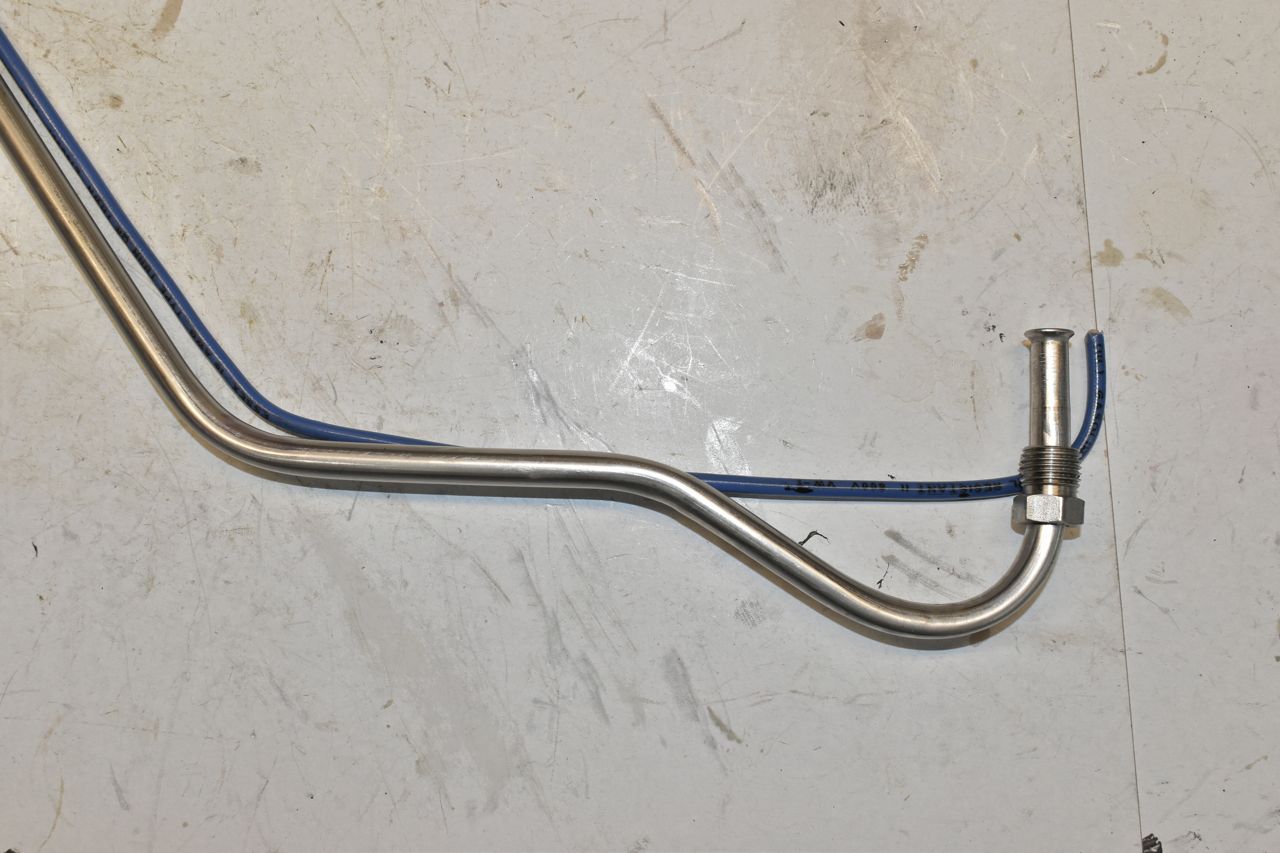

I use stiff wire to get a rough pattern, then I bend using the wire as a guide and fine tune as I go.

Since the bender has a radius, you have to plan that into the line, where the wire guide is ideal, it's not like that on the final piece so you have to compensate.

The critical dimensions are the same, just have to deal with bender radius.

I'm happy with the line up and it's all stainless including the nut so no worries about internal rust.

I put a new inlet line to the fuel pump as the end was rock hard but the rest of the hose was soft as a wet sponge. I can only surmise it's the ethanol doing that.

It's so squishy, I'm surprised it didn't collapse.

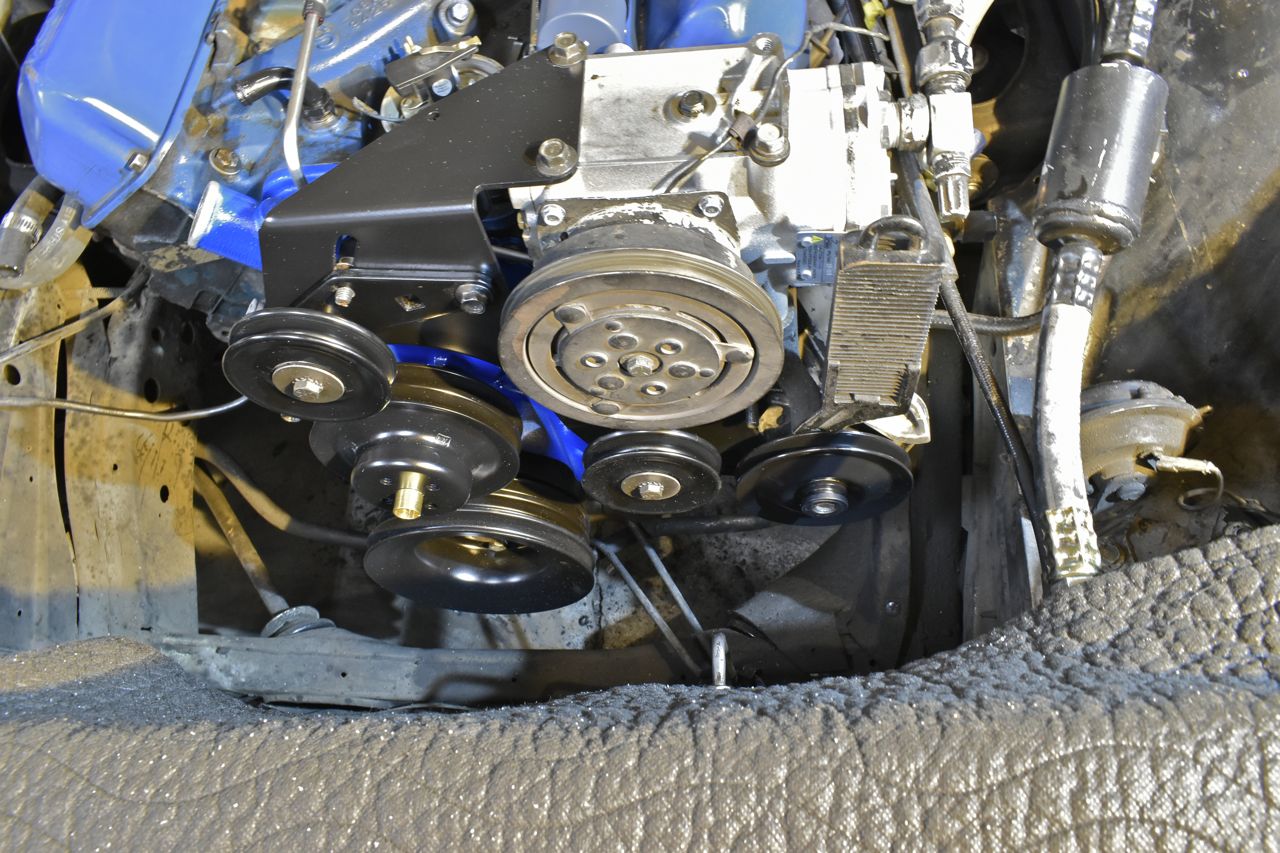

Upper compressor and tensioner bracket.

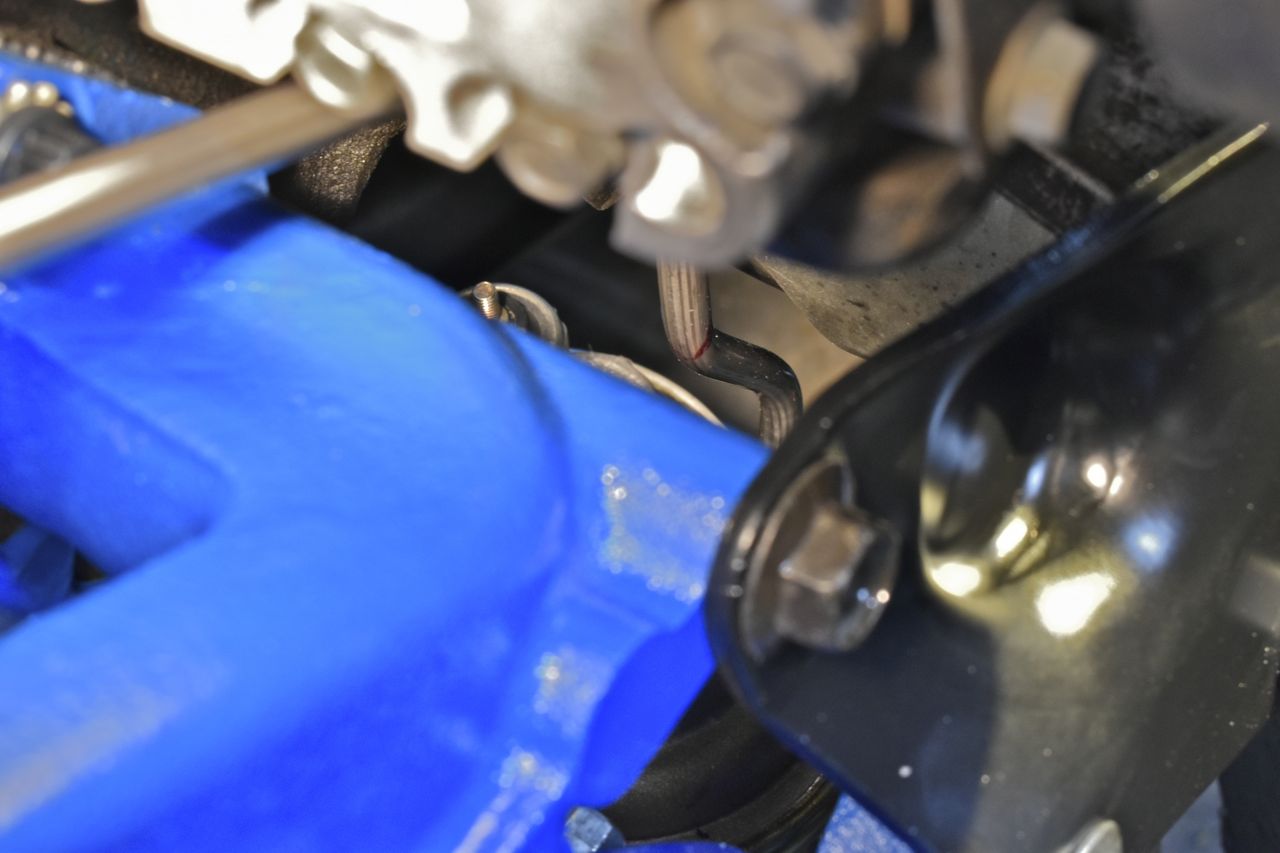

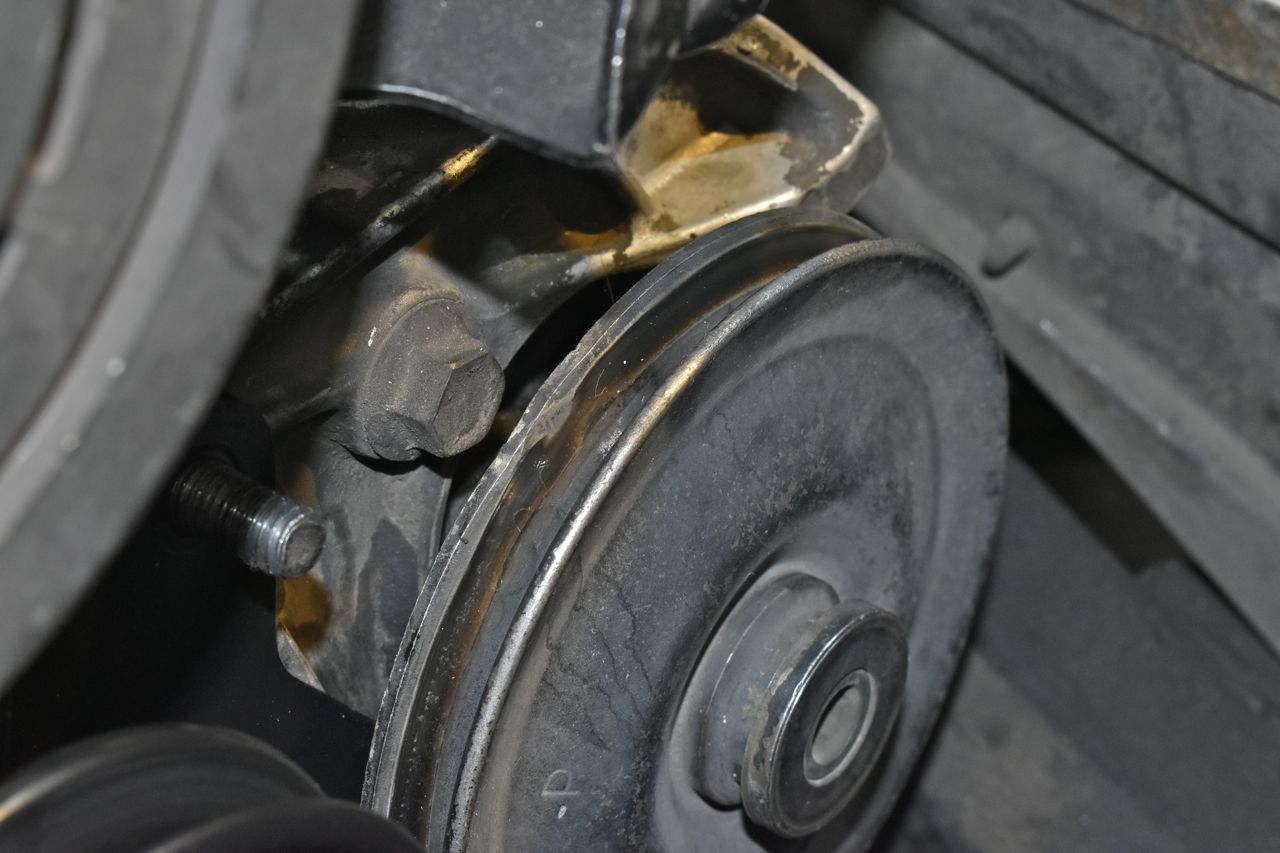

So I found this, I mean why not, nothing surprises me on this car. The shoddy workmanship is aplenty. The power steering pulley looks like it was pried on in 3 places and the axial run out is about 3/16" which is way too much for a belt. The belt was not happy.

Plus it was pinched here.

Donor pump.

You can see where it was pried on.

Donor pulley stripped painted and installed along withe A/C idler and tensioner pulleys.