1968 Ford XL Repairing Whilst Keeping It Roadworthy : 31 Ignition

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74After finishing the clock, let's get back to where I left off.

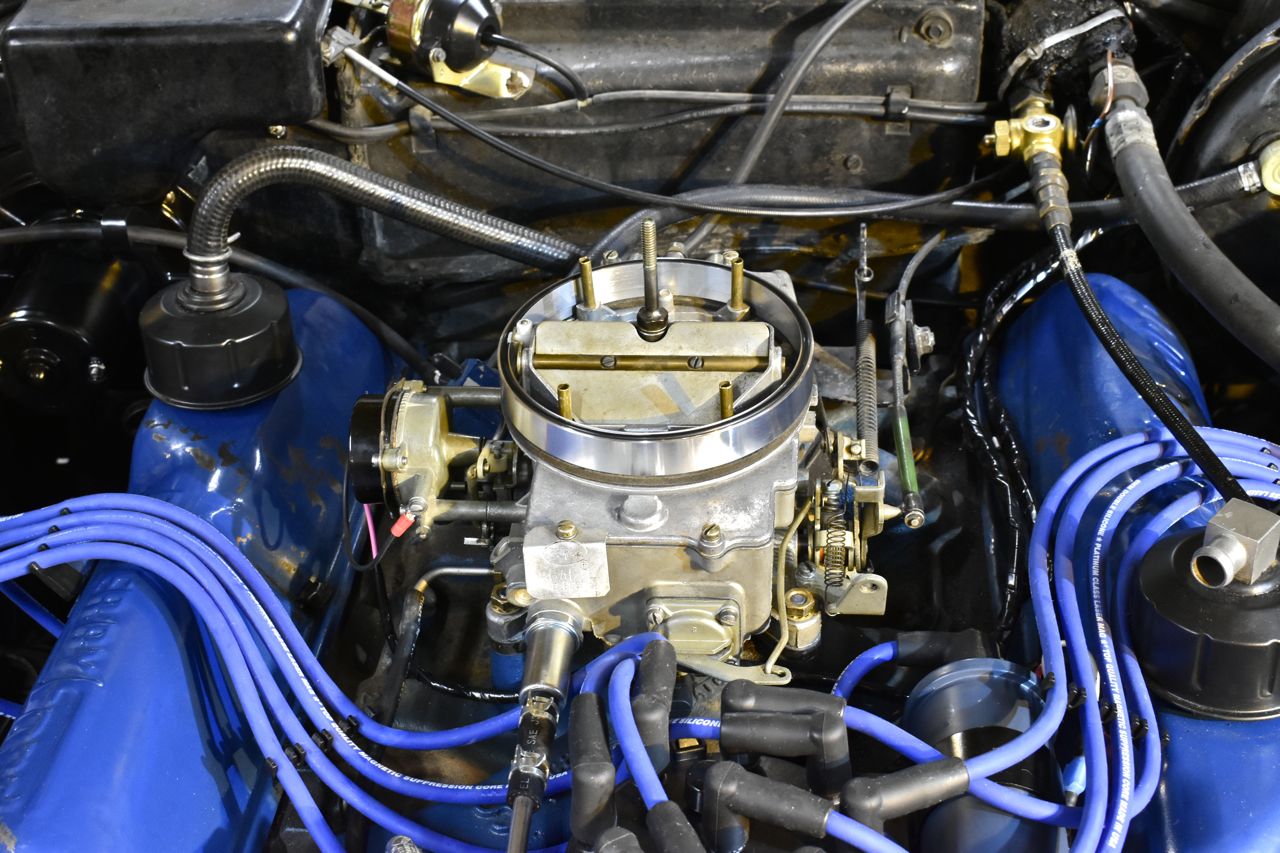

I bought a spacer for the air cleaner since it hits the electric choke housing and rubs on the distributor HT wires.

What a shocker it doesn't fit, the I.D. is too small.

It's as though they forgot to cut it down all the way.

This was a bear to set up in the independent 4 jaw chuck perfectly circular as it's so flimsy.

Fits now, but still a bit too tall.

Took about 1/3rd of its height off and now it's perfect. I used the loosely wadded aluminum foil atop the air cleaner and then lowered the bonnet carefully and measured the crush. I have about an inch and the air cleaner is of the choke and distributor wires.

Although the O-ring works best down facing the carb and the regular paper gasket atop the aluminum spacer.

The Optima came and that was installed.

Now it's time to start it after all that work.

So the charging system works a treat now, at hot idle the battery voltage was 14.10 and with the HVAC blower on high, the battery voltage was still 14.10 at idle. It didn't even change a hundredth of a volt and all the lights are nice and bright. I am very happy with that.

However I am not happy with the ignition system. So this mix-n-match system is mentioned on several popular automotive forums and I thought I'd try it since I have extra GM 4 pin modules and it simplifies the wiring for now. This still is a temporary thing so I can enjoy the car now whilst I finish those other two 66's. However this GM-Ford alliance of an ignition system does not play nicely together.

The problem is the coil overheats. The timing however is very stable. To be honest I was kind of hoping this would work as it was praised on several places. However my one suspicion was no one ever posted scope readings.

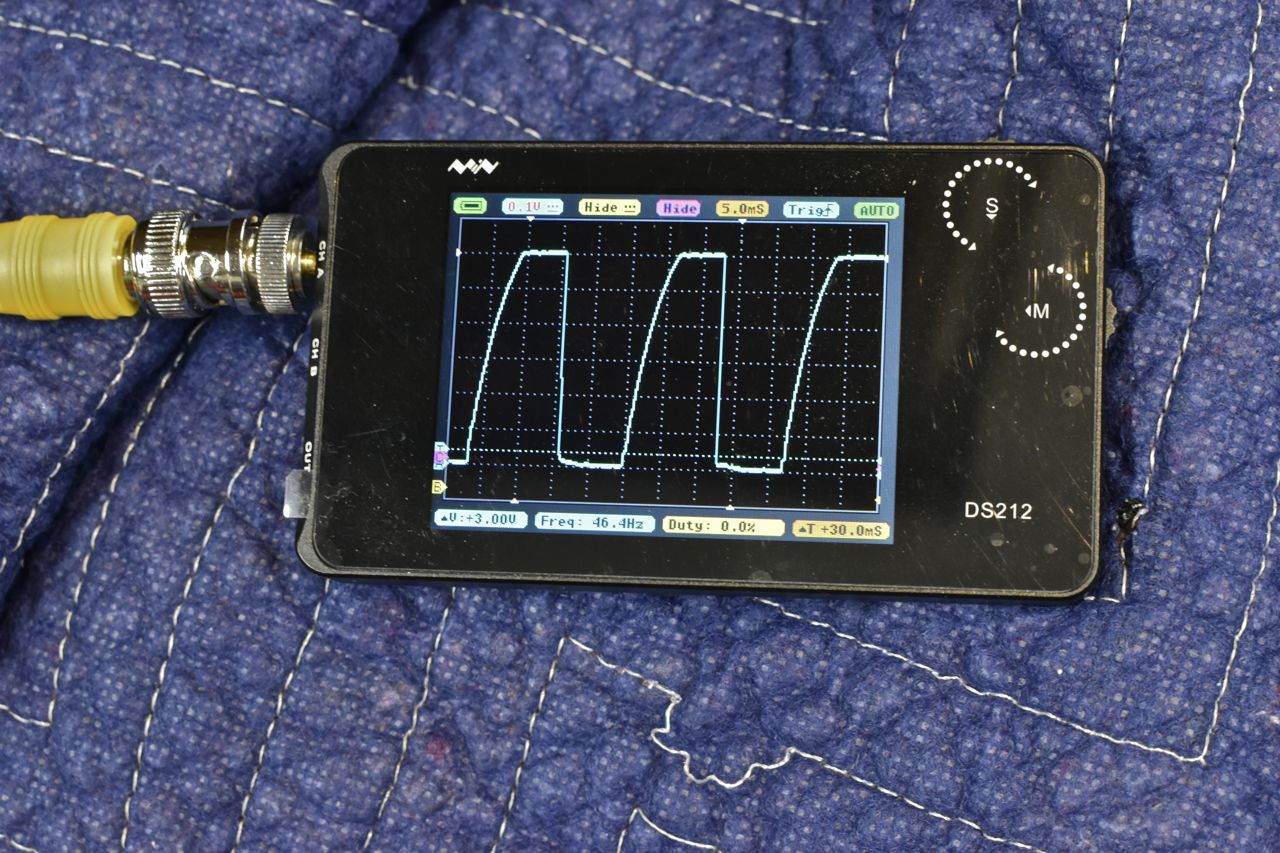

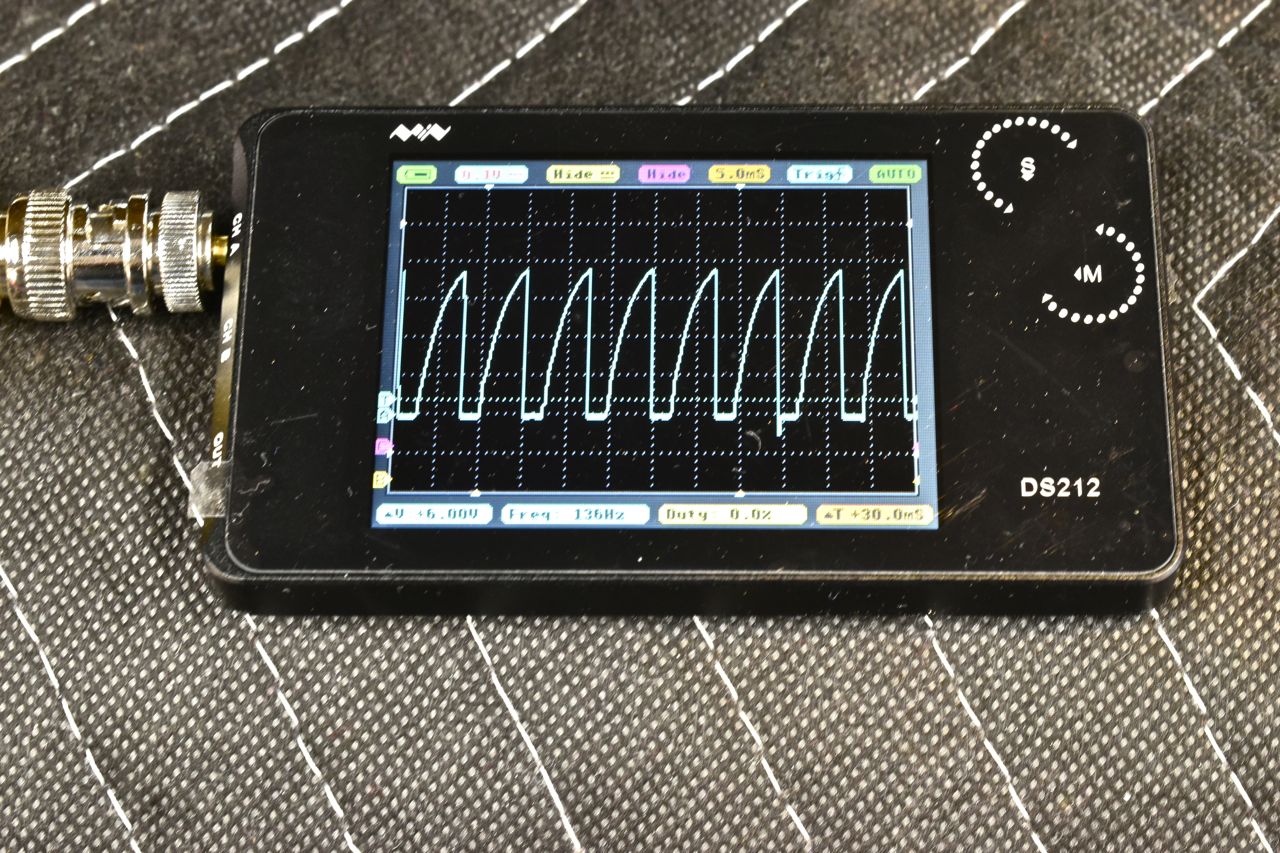

Well, here they are.

This is the primary coil current. Well no wonder why it's overheating. This is at approximately 710 RPM. The coil magnetic core is saturated and the current is hitting the limiting function on the GM module of about 5-5.5 amps.

Now I'm using a Pico amp probe clamped to the (-) coil wire.

I just want to mention you do not need expensive lab grade equipment for something like this. This is a cheap 100 dollar 2 channel O-scope that fits in your pocket. I think I paid more for the Pico amp clamp. But this scope is perfect for this, plus it has a signal generator you can set up and it will output on a jack. It's perfect for audio work too.

This setup is also extremely useful for checking DC motors like blower motors or fuel pumps. You can see the commutation action and see if you have bad windings or brushes on a motor that might be on its last legs, especially a fuel pump in the tank.

It's probably hard to see but the amp clamp is atop the engine near the coil.

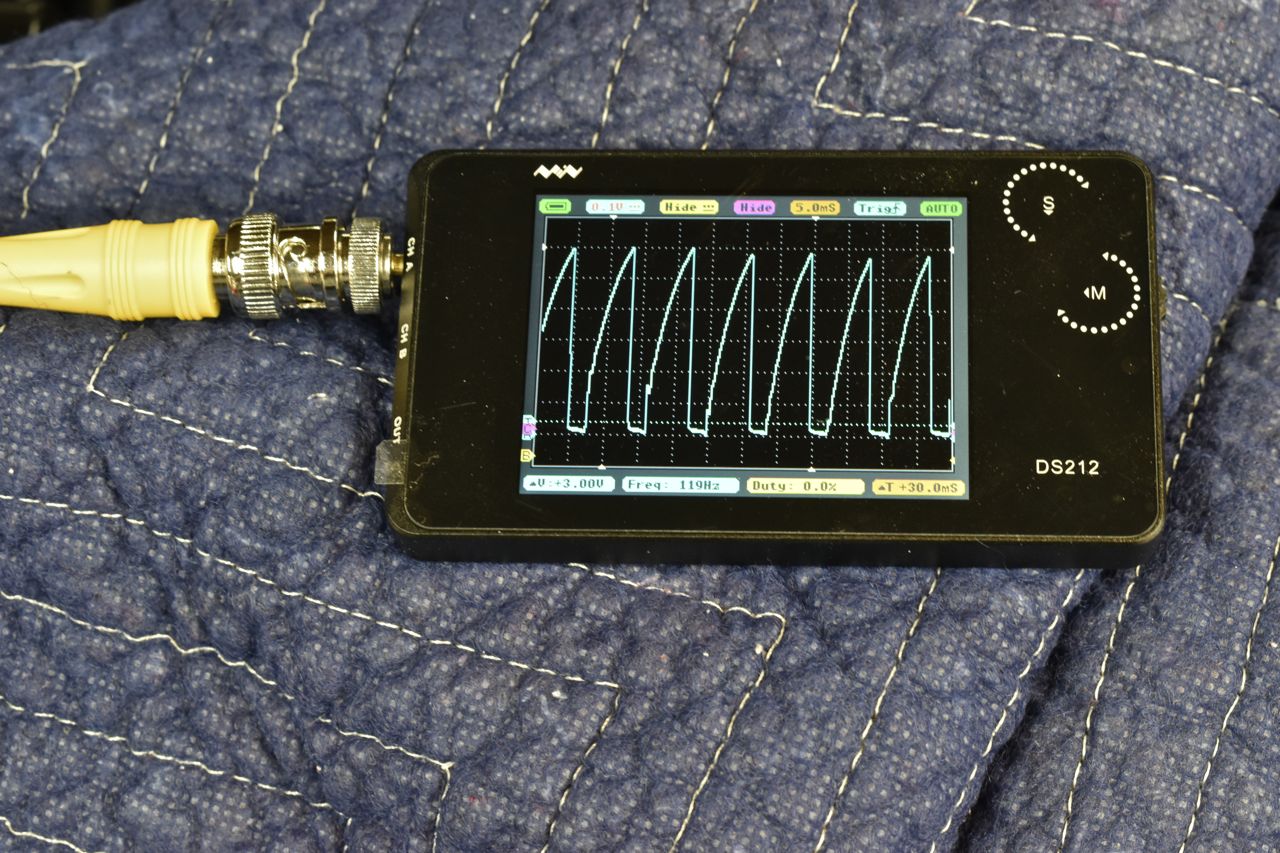

This is at roughly 1760 RPM and the coil dwell is happy here and higher RPM's. It's just at idle it saturates and the coil and module just dissipate heat when that happens. It doesn't take much to see that if the module limits 5.5 amps then simply put I^2 x R. Where 5.5^2 = 30.25 x coil resistance of 1.5 ohms = 45.4 watts. So the coil for the time it saturates has to dissipate the heat of a 45 watt light bulb. Add to that sitting atop a hot engine and then blocked off from air flow from that idiotic 1968 compressor bracket, no wonder why it overheats.

Now according to this website Ford - GM HEI Ignition it should auto adjust the dwell to prevent coil saturation, but it doesn't. This guy says that the controller in the GM HEI module is the MC3334. I have no way to verify that. But in looking at the data sheet it looks like the module is trying to offset the voltage at the pickup coil to alter dwell. If that's really the case, then the pickup coil in the distributor has to have a certain electrical characteristic for this dwell control to work properly. In other words at a certain RPM the pickup coil has to output a certain voltage.

I do not think the Ford pick up is properly matched to the dwell correction in the module.

It's quite clear this system does not work happily together so for anyone interested, don't bother. For giglesnorts I'll put the amp clamp on a genuine GM distributor with this module and have a look at the primary coil current.

With that I did order the California only Duraspark I module and coil. However it will not be here for a week so in order to use the car I added the resistance wire back in between the coil and module and bought a heavy duty version coil.

I raided the resistance wire out of a wiring harness. I have a huge bin full of 3rd gen wiring harnesses. So I unwrapped my harness and gave myself two coil wires, one regular wire and one resistance wire. Then I taped it back up. So when the Duraspark I module arrives I can just use the other wire instead.

What a pain in the butt.

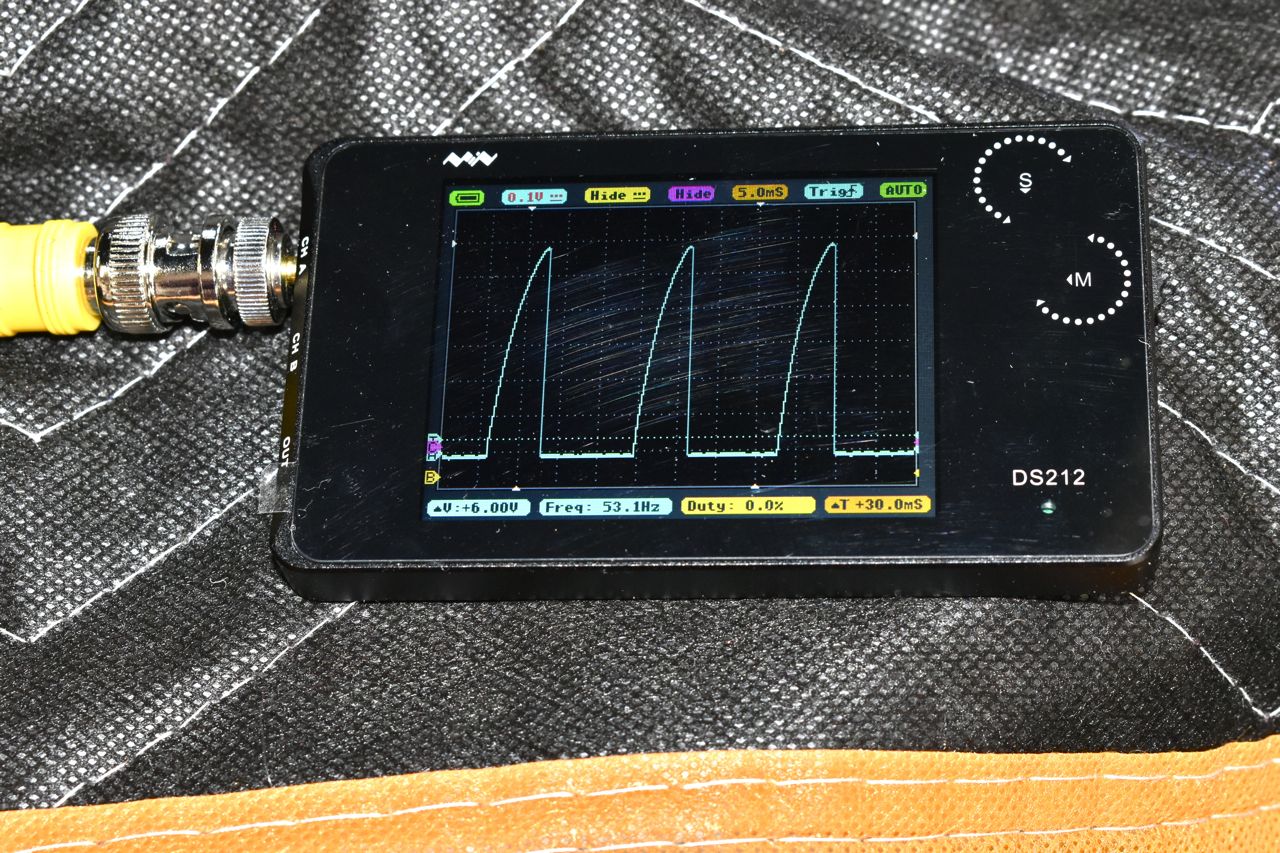

The car runs the same. But here you can see the dwell was stretched by the module not sensing current limit early. The coil still gets warm-hot, but not blistering hot like before. This is at idle.

This is a higher RPM.

It'll be interesting to compare this vs a genuine GM HEI distributor then to the Ford California HEI system. At least it's drivable (well that's relative) for now.

About the scope,

I bought these attachments to work with the little cheap pocket Scope and all this has been very handy on vehicles. Being a 2 channel scope I bought two capacitive spark plug wire clamps and I use one on the coil (if possible) then another one on cylinder one as a sync. That way I can look at the secondary pattern and see if I have a problem cylinder.

All this is a cheap investment on saving hours of aggravation, guessing and needlessly loading up the parts cannon and firing it at a vehicle.

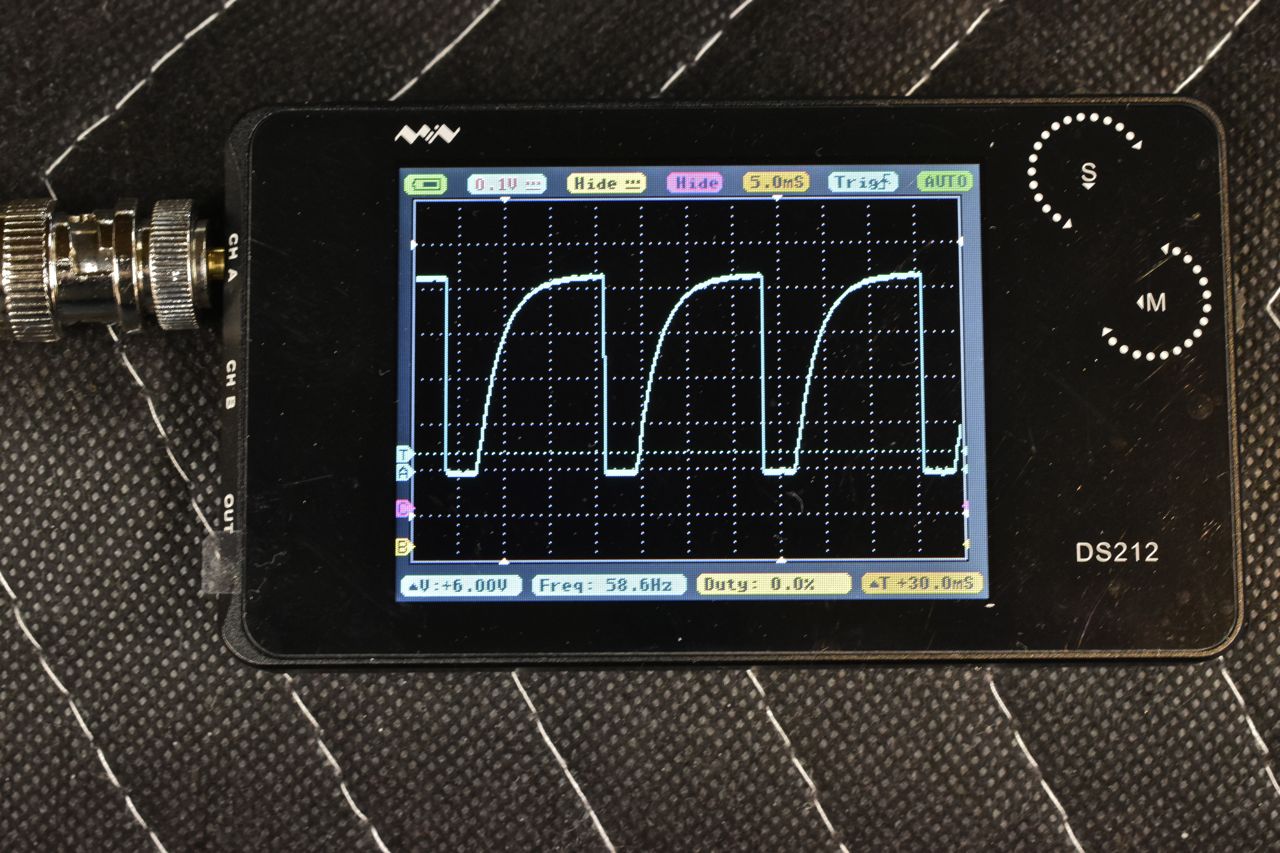

Yesterday I had to change the oil in my Caprice Classic and had an opportunity to take a primary reading on a complete all GM HEI system. And it's a confirmed kill. The Ford distributor and GM module do not work well together as the automatic dwell adjustment isn't electrically matched to the Ford pick up coil. It is matched to the GM pick up coil.

This is hot idle.

There is just a tiny hint of coil saturation and that's it. It's like this through the useable RPM range.

Later this week the Ford HEI system should arrive and it'll be interesting to see how well that California only Duraspark I does at controlling the dwell.

Click here to continue to part 32