1968 Ford XL Repairing Whilst Keeping It Roadworthy : 04 Air Conditioner Idler Pulley

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74Air Con Pulleys Continued

This is an alternative method to measuring the correct height.

Now the tensioner.....

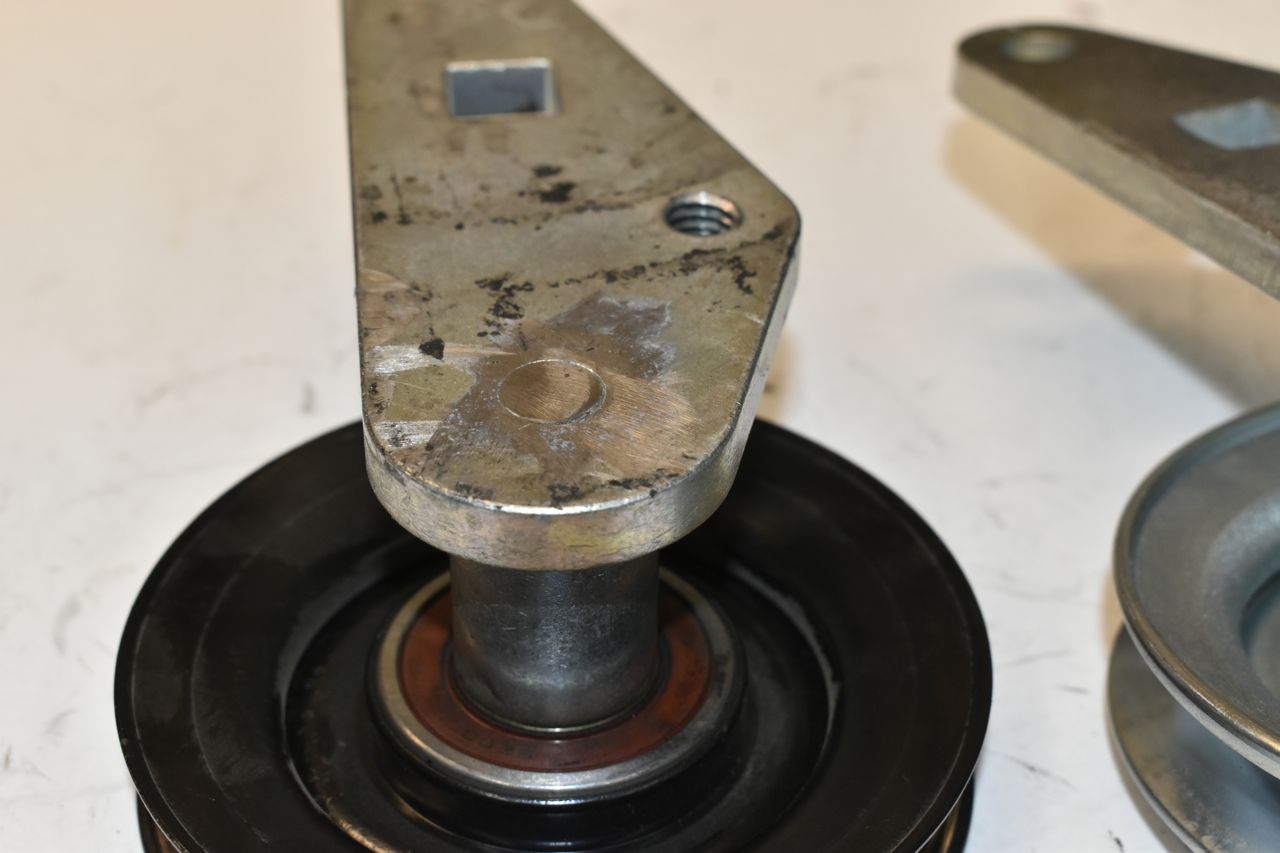

Here's my beef with the aftermarket tensioners. The one on the left is the one I took off the XL. The one on the right is for the same application but these are the ones I've been buying for the '65/'66 pulleys. I just simply keep the pulley and toss the rest.

These are the part numbers for the '68 with FE tensioner.

My first problem is this. The bolt sticks out the back and this whole back needs to be flush. I wonder if the other brand they used had the same problem.

guess so.

Second problem I have with these. This is the tensioner, this is what puts the tension and force on the A/C belt. That belt in turn pulls down and away on the pulley. There is sheer and tension all focused on the bolt and bracket threads. It's a small bolt in comparison. The idler pulley had that big honking bracket with a large press fit piece and the idler only slightly deflects the belt and there's not a lot of tension on that assembly. But this does.

Now the bolt is tempered, but the bracket isn't. It's soft low carbon steel. Time to bolster this.

I'm going to enlarge the hole first.

This is how I know this steel is soft, that step bit drilled through this like a hot knife in butter.

I machined a shaft stub that's 0.002" oversize on diameter and 0.025" shorter in length on the back so it leaves a small pocket. I will TIG weld the backside after pressing it in and this will spread the load on the soft steel.