1968 Ford XL Repairing Whilst Keeping It Roadworthy : 43 FE Engine Shortblock - Plugs

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74Short Block Assembly Continued

The Melling kit unfortunately doesn't end there with incorrect parts.

The cam plug on the right side is the Melling and the Dorman plug on the left. The Melling plug is too deep. The Dorman plug is the correct depth.

The one thing I do like from the Melling kit are the 1/4" NPT pipe plugs, they are a wee bit shorter than the Dorman ones and this comes in handy for a few places.

Mixing sets together this is what I need for this block. For a someone whose new to old cars, stuff like this would drive them crazy.

Parts for the rear of the block. I took it off the stand and it's face down on a pad. I had previously drilled and tapped the rear oil holes for 1/4" NPT plugs.

All the parts had a light coating of Ultra Black RTV when installed. I use an old bushing can to install the cam plug, this one is the perfect size.

The Melling cam plug would sit too high and interfere with the starter locating plate (what some call the block spacer plate).

Same treatment for the core plugs.

The two front plugs. Now the top plug was originally a dribbler for the cam sprocket and chain. I just drilled a hole in the centre of the plug to spray oil. I'm using a HV oil pump so I've got some wiggle room on oil distribution.

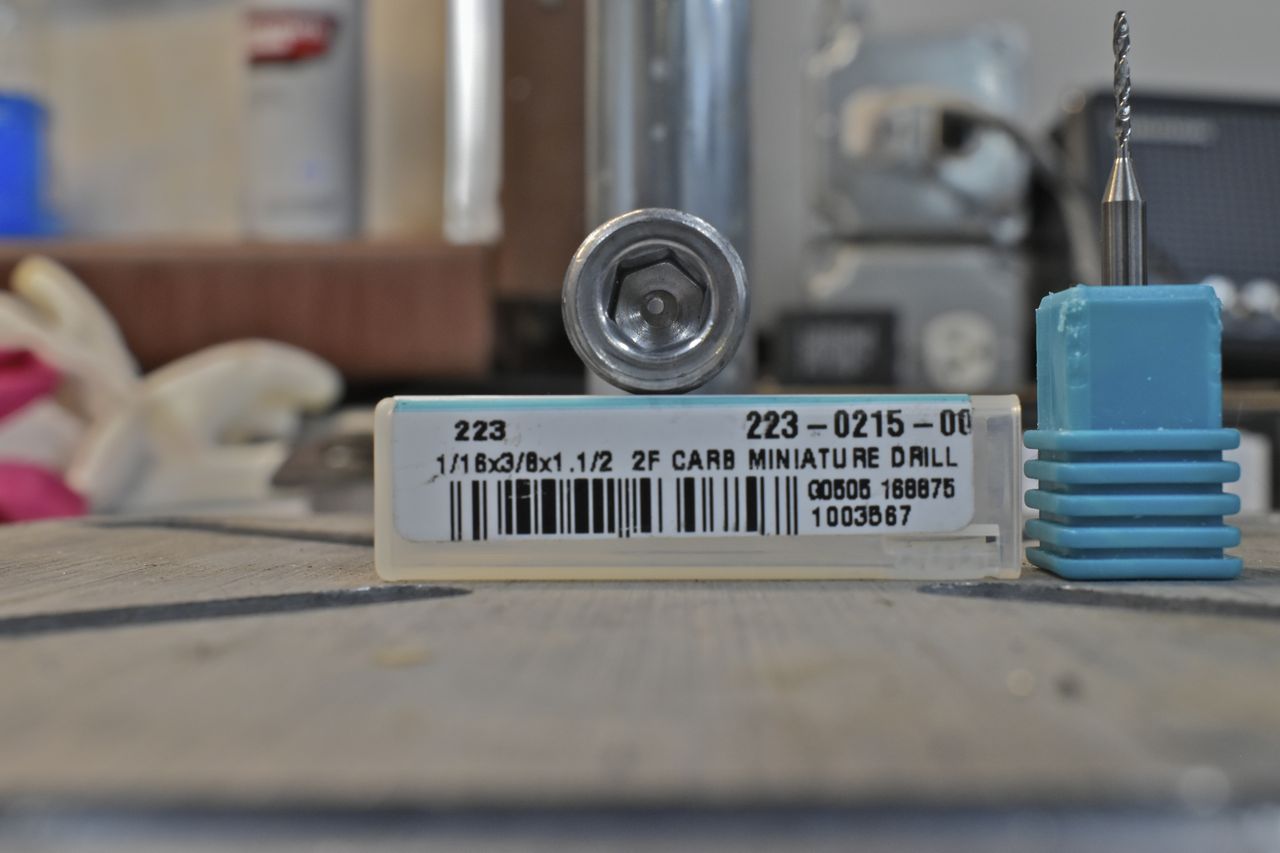

Drilling the top plug.

This plug takes some careful planning for thread depth so the plug doesn't end up in the lifter bore.

Nor is the plug so long it sticks into the distributor bore.

Rest of the oil plugs installed.

Now the camshaft can be installed.

You don't need to use the original 'C' spacer as they are moulded on the new sprockets.

Been down this road with Melling double roller timing sets before. The pin hole bored into the sprocket is too small by at least 0.002" You'll end up murdering the pin if you try to install it. Sad part is it's a Melling timing set with a Melling camshaft and the cam comes with a new pin and it doesn't fit.

Melling you need to get it together!

I have to lightly polish the pin hole till it just takes light taps of a hammer to install as I do not have a reamer for this size nor should I need one.

I used Locktite on the cam plate retainer bolts and used assembly lube. The cam sprocket bolt is just hand tightened for now.

Next up is the crankshaft and polishing it.