1968 Ford XL Repairing Whilst Keeping It Roadworthy : 66 Large Bearing Ford 9-inch Overhaul - Prep & Re-assembly

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74

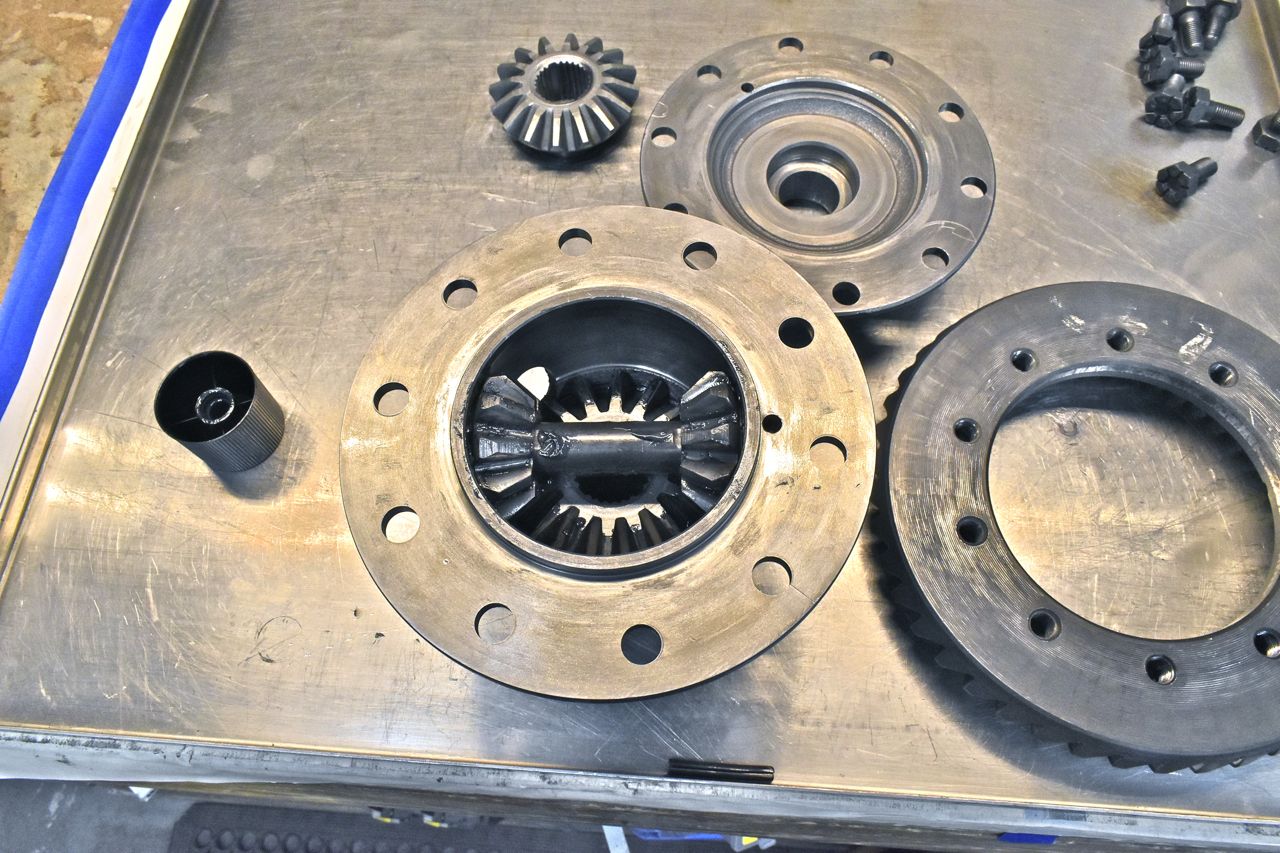

All the parts prepped for assembly.

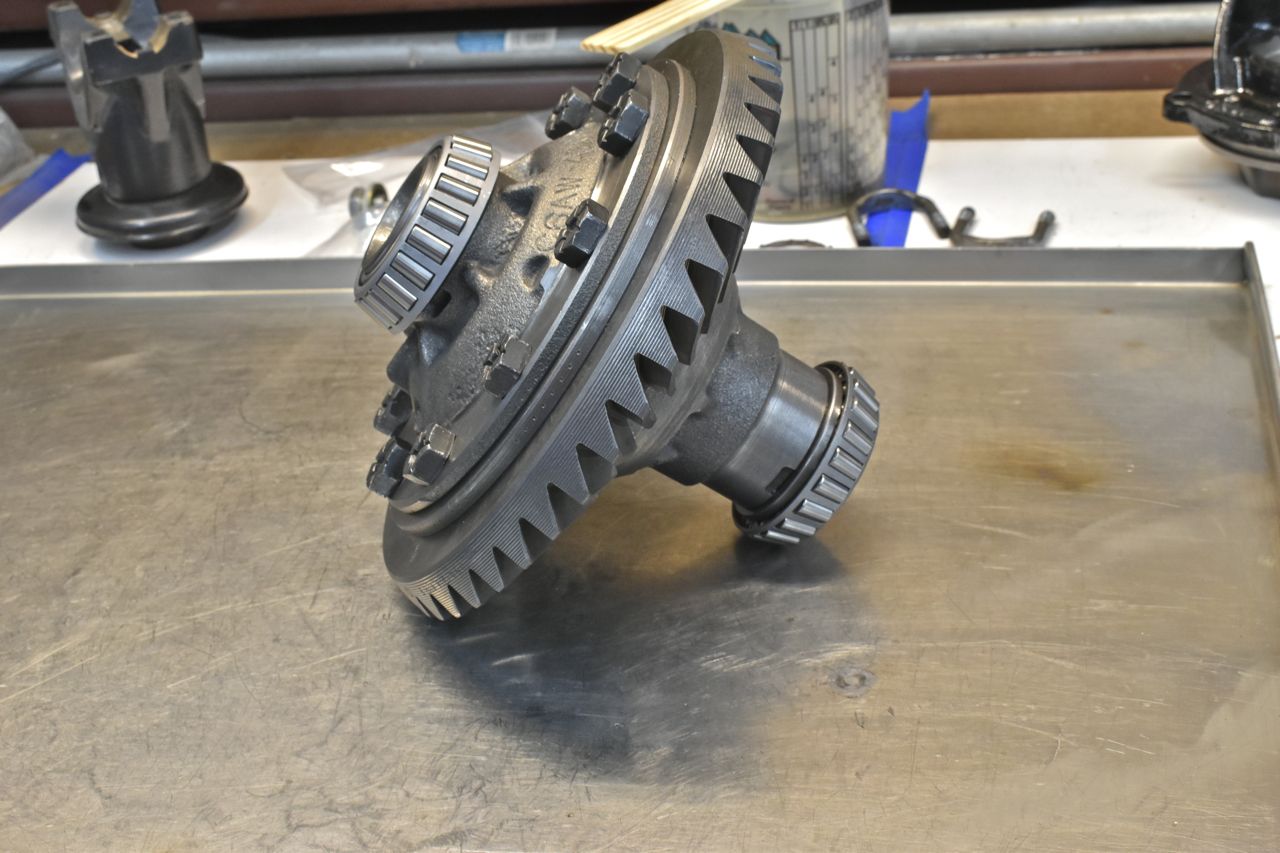

The differential innards are ready for the ring gear and being drawn together.

This is just to get it started.

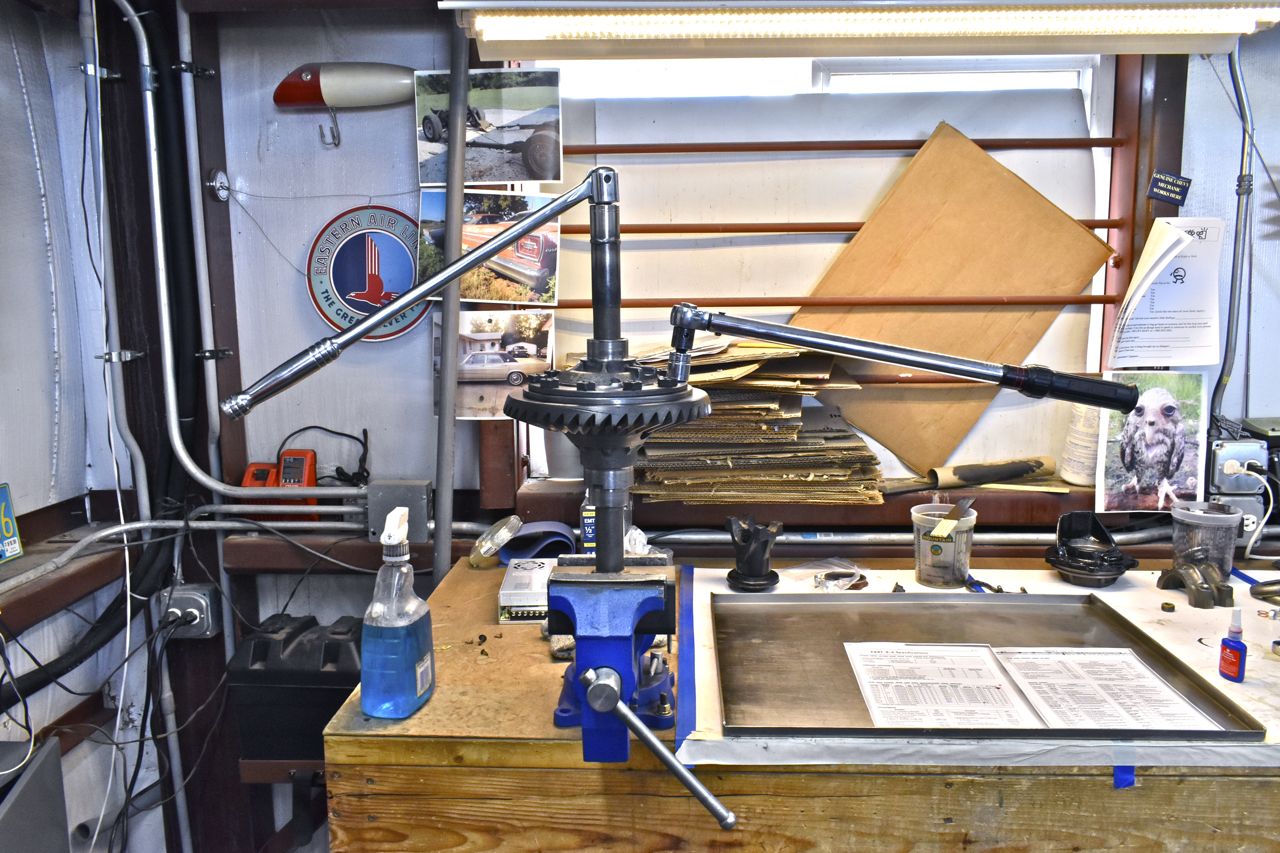

This is a jig I made to hold 28 spline differentials. This is made from a 28 spline Ford 8.8 axle shaft cut down and welded to square tubing.

This makes it easier to draw up the ring gear and squeeze everything together.

Once the assembly is drawn together then I can insert the cross shaft roll pin.

Now I can add the Locktite to the ring gear bolts.

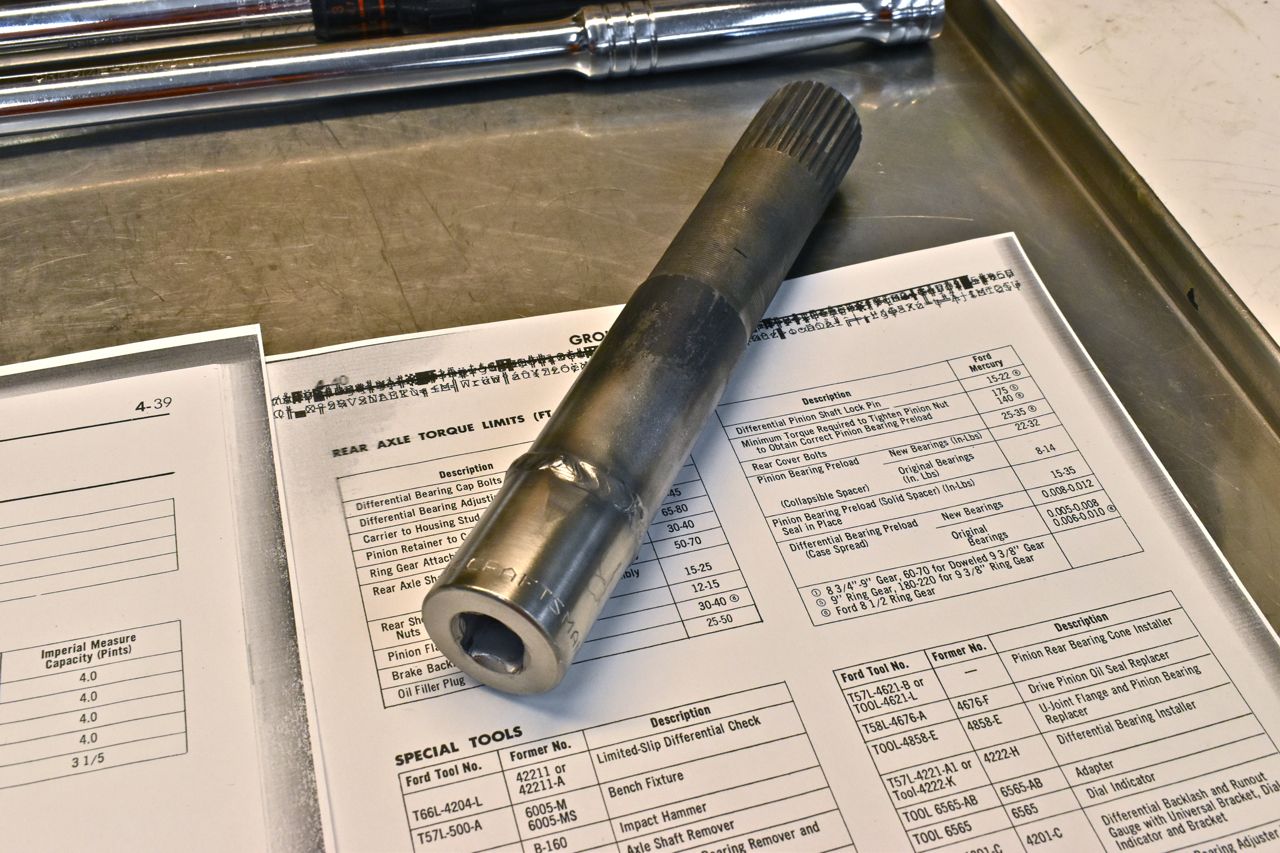

Ring gear torque specs.

Here's another tool I made from another 28 spline axle shaft stub.

With this I can hold the differential with the top breaker bar and then torque down the ring gear bolts.

Done.

Cleaned and pre-lubed.

New carrier bearings.

I used an old suspension bushing outer can to press the bearing on as it was the perfect size.

This is the perfect size to just press on the inner race without pressing on the roller cage.

One and done, well for now anyway.

Click here to continue to part 67