1968 Ford XL Repairing Whilst Keeping It Roadworthy : 61 Large Bearing Ford 9-inch Overhaul - Axle Out & Inspection

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 741968 Heavy Duty Ford 9" Axle Rebuild.

This car has now 402,000 miles on it and back when I did the back yard refresh on the spare Z-390 engine and installed it, I had to remove the transmission. Obviously first was to remove the propshaft and my curiosity got the better of me because after the propshaft was off I found myself staring at the pinion on the rear axle and so up on the lift I decided to see how the bearing felt and spun the pinion yoke by hand. I wish I hadn't. It felt awful, as in it felt like brinelled bearings. Since I was already immersed in the engine project I took a page from Derek from Vice Grip Garage and pretended I didn't feel that. However I knew this would be have to be revisited soon.

And here we are.

In order not to have the car on a lift for ages plus the ring and pinion might be so worn I would have to find a used set as new sets in this gear ratio do not seem to exist, I decided to rebuild the axle from the '68 XL parts car; the gold XL's nearly identical twin. The parts car '68 XL only has 60 something thousand miles on it so I figured the rear axle would be in much better condition. I was right and wrong on that assumption. I'll explain that later.

A little bit about these full size Ford banjo axles in this generation of full size cars (1965-1968), all 1965/66 full size models came with a banjo axle. This was going to be the 9" and 9-3/8" variant. The 9" came in two classes; light duty and heavy duty. The light duty Ford 9" is a small axle shaft and small axle shaft bearing, even the differential carrier bearings are smaller. The heavy duty Ford 9" axle comes with larger axle shafts and axle shaft bearings, along with larger carrier bearings. Basically the only interchangeable parts between the light duty and heavy duty Ford 9" are the ring and pinion gears and perhaps the spider gears.

However both the heavy duty and light duty are all mostly 28 spline axles along with a non-nodular iron (weaker) cast iron third member drop out section. I do believe the galaxie 500 7 litre models ended up with a nodular iron third member and 31 spline axles.

By 1967 Ford dropped the light duty Ford 9" banjo axle in favour of the WER axle, which is a Salisbury type axle and is the predecessor to the now common 8.8 axle. However this WER doesn't share the same parts as the 8.8 axle and there are no major parts for this WER axle aside from seals and bearings. For 1967/68 full size if your car came with an FE engine (390 or 428 as the 352 was dropped) you received the heavy duty Ford 9" axle. If your car was a Windsor or inline 6, you ended up with the WER axle.

Since the '68 gold XL car and the '68 XL parts car are both 390 FE cars they both have the exact same axle; the heavy duty 9", 28 spline, open differential with 2.75:1 gear ratio.

Here is the spare axle to overhaul for the gold '68 XL.

Replete with New Mexico popular store branded tyres from the 1960's.

Another fun fact of the heavy duty vs light duty Ford 9" axle in full size 65/66 models is that the light duty Ford 9" also used 1310 series Cardan joints which are small and light duty. The heavy duty Ford 9" uses the more popular 1330 medium duty Cardan joint. You can see the difference in the yokes. The smaller yoke laid atop the larger yoke is from a '65/'66 light duty Ford 9".

On this axle from the parts car '68 XL it's been leaking from the yoke nut as there was sealant on it from the factory. So it was slinging oil from the inside the yoke.

To get this party started, buzz off the pinion nut and use a puller to remove the yoke. This method shown here seems to work just fine and the yokes I've pulled aren't on that tight where you risk damaging the yoke. You can also build a plate that bolts to the U straps and yank on that if you wish.

I have never been inside this axle and didn't know what to expect. I will say this, the initial fluid that came out was clean. Someone had changed this oil sometime between 1968 and the 1980's when the car was parked for good.

Now I did get the '68 XL parts car running and driving and I did replace all the rear brakes and obviously I stole them for the gold '68 XL.

This is a 28 spline heavy duty axle shaft.

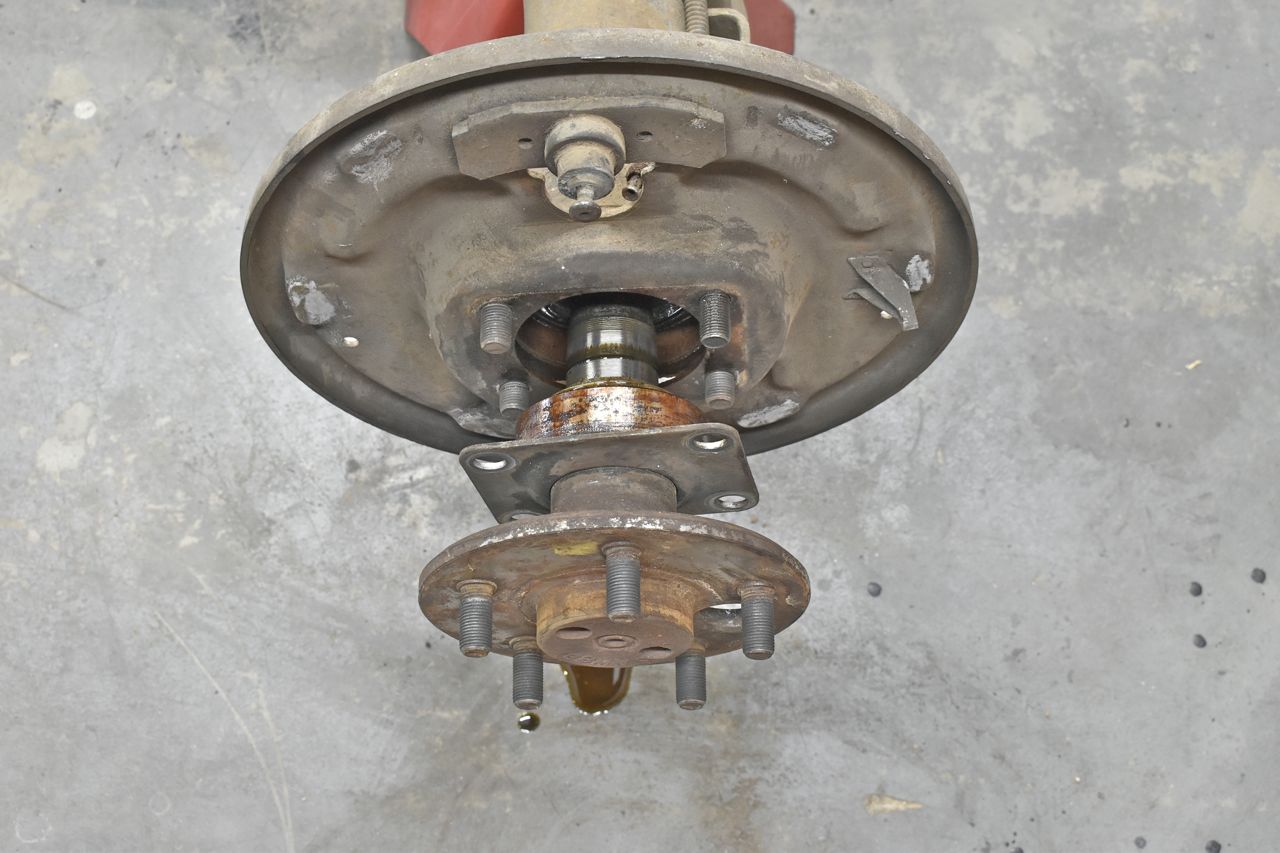

Even with relatively low miles, that axle shaft bearing has seen better days.

Well at least the other side looks the same.

Now the good news is where the seal rides on the shaft is in very good condition and no wear other than a polishing of the shaft. So as you can see the Ford banjo axle uses sealed bearings and the seal holds back the axle lube before the bearing. So whatever grease in the bearing at the time of manufacture stays in there. So 53 year old bearings just need to be replaced because the grease will be hardening plus if there is any water ingress you'll have corrosion in the bearing and it can fail.

Again a nice seal area on the shaft. If this is worn to the point you can feel it, you have no choice but to replace both axle shafts and that's $$$

Someone in the past also put in new axle shaft seals. This is probably what saved the axle shafts with newer rubber on the seals still soft.

Just giving the rest of the axle housing an inspection.

So this is interesting, you can see oil seeping past the rear welded cover in the lower left. I can also see rework manual welding on the cover. Looks like this axle had a bad on the production line back in 1968. I'll have to weld or re-weld that area and leak test the housing.

A close up.

With the axle shafts out and the backing plates off the pinion support can come out and drain the rest of the oil. Remove the bolts and a light tap of a plastic mallet to break the pinion support free is all it takes.

Click here to continue to part 62