1968 Ford XL Repairing Whilst Keeping It Roadworthy : 51 Steering Box

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74Practically Done, well with the engine anyway.

It's been awhile, but I started driving it today. Now here's the rest of the story.

The old Y390 removed. With my super high tech flushing system attached I washed out the evaporator with acetone. I'd pour a pint or so in, then force it through with compressed air. I rinse and repeated till the acetone was clear and then blew it out with air till nothing more came out.

Whilst the engine was out, I noticed much unhappiness with the steering gear. It was dripping oil off the Pitman shaft/arm and I wiggled the flexible coupler and half of it just broke off. WTF? Plus the coupler was so far down on the input shaft the safety catches couldn't engage.

This car was an accident waiting to happen. At this point my better half and I renamed this car "The Death Trap".

I hadn't planned on doing the steering system at the same time as the engine, but I really have no choice now.

Then I noticed this. The Pitman shaft nut is not on all the way. The steering gear looks original but the Pitman arm looks much much newer as in recently replaced. What was odd is the nut wasn't on all the way, but it took an act of congress (for whatever that's worth now-a-days) to get that nut off. Whomever changed the Pitman arm galled the threads on the Pitman shaft and nut.

And the Pitman arm was loose on the Pitman shaft as it is just fell off after the nut was removed. It's a taper spline and the nut has to be fully tightened otherwise the arm is loose on the shaft.

The steering wheel was so bad you could move the wheel at least 20-25˚ before you felt the torsion spring in the steering gears input shaft.

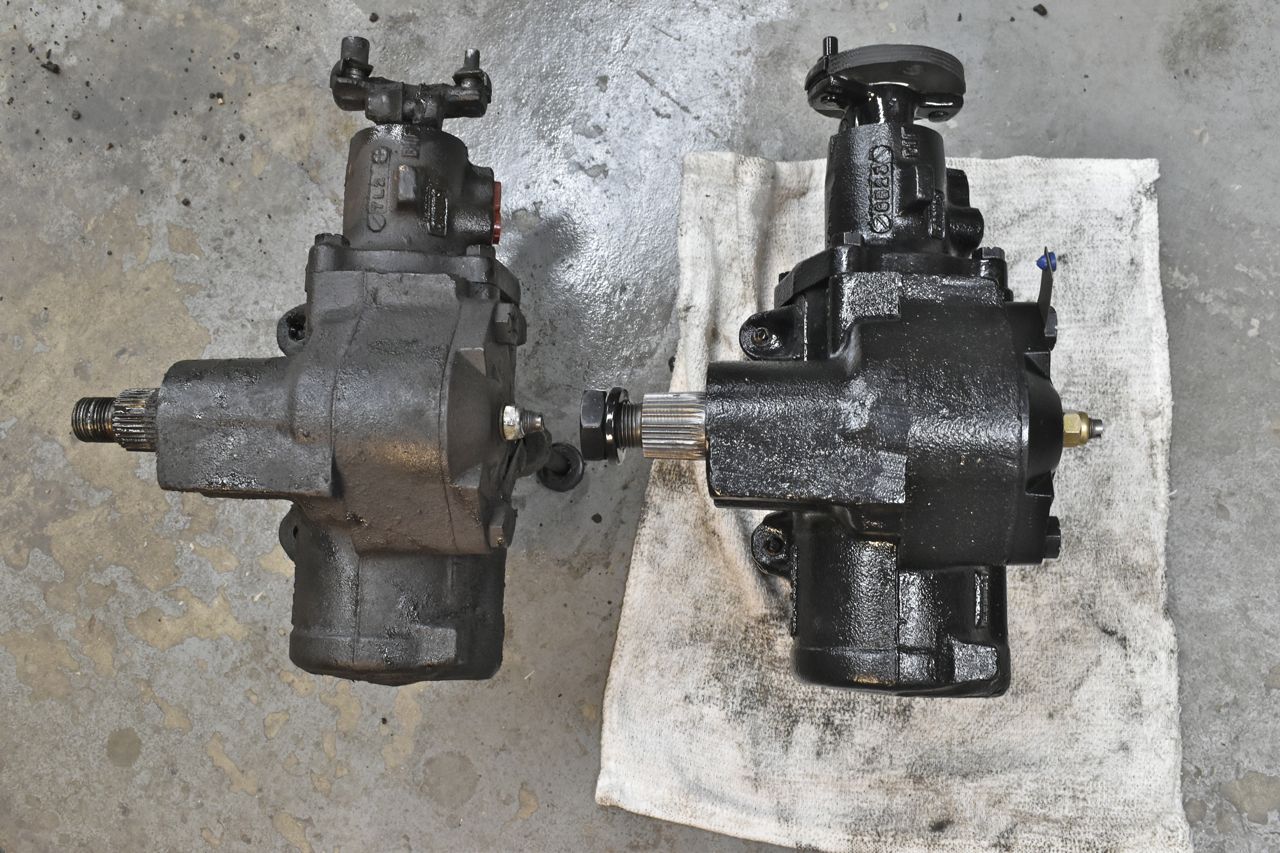

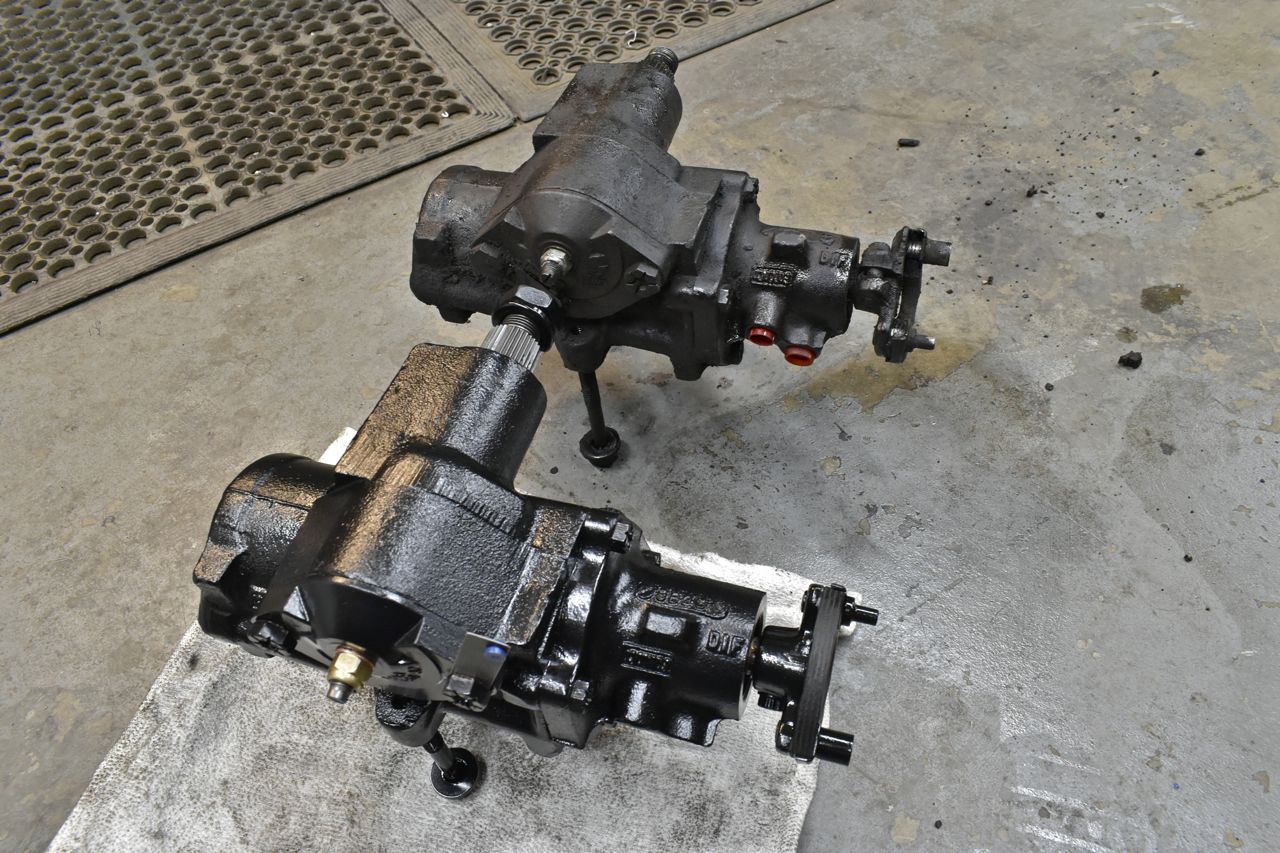

Well I have two spare steering gears and one pump to R&R.

I didn't cover the specifics because I covered these items in other threads to a very in depth level. I will just say some things worth noting. The quality of the Edelman kits has really fallen and that RPS pump kit isn't that hot either. I had problems with the main Teflon piston seal in the Edelmans and the pump bushing in the RPS kit.

The original pump shaft bushings in old kits are made by Clevite but now discontinued, these bushings are made by someone, dunno, but the OD is a bit too big and it's a nightmare getting it pressed into the pump face. By the time I was done pressing it in, the driver had partially distorted the bushing from the unnecessary force it took to install and then many many many minutes were spent with jeweler files dressing out the distorted end. What a waste of time that was.

The Teflon seal in the Edelmann kits was different in the same part number kits between the two boxes. One had a white Teflon seal and the other had a blue Teflon seal. The white Teflon seal would not stay compressed to installed in the gear case. I ended up shearing it. The blue Teflon seal almost seemed too complacent to stay compressed and the piston just fell in.

I've R&R'd 3 of these 3rd gen Ford (not Saginaw) steering gears and never had problems like this. Another thing to note is the '68 steering gears do not have the Pitman shaft bushing like the '66's do. It's the same C6 part number on the steering gear case, it just looks like Ford cheapened out and just use the cast iron case as the bushing against the hardened Pitman shaft.

I took the best parts from both used gears to make one decent one. The one of the XL is on the left.

Isn't that just nice..... The other half pretty much fell out. That was the only thing coupling the steering wheel to the steering gear. If that would have broke whilst driving total loss of control would have ensued as the safety catch pegs were too far away from the plate to do anything.

There's the thread they galled. So instead of buying a die and fixing it, they just rammed the nut up as far as they could and wherever it stopped, it stopped.

Well it's done. Now there's maybe 2-3˚ of steering wheel movement before the torsion spring is felt. Basically it's night and day difference and the steering just won't plain fail catastrophically.

For now the evaporator is plugged to keep moisture and debris out. On a slightly different topic, since it's pictured, the brake booster, withcidentally is incorrect, had a check valve in which didn't fit the rubber grommet so they glued it to the rubber grommet. Holy cow.

I'm all for freedom to do what you want but some people need not touch vehicles. By the way the check valve was bad at any rate.

Click here to continue to part 52