1966 Ford LTD Resto-Mod : 024 Custom Build Exhaust - LOBSTER-TAIL !!!

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65Hi All,

Next up on the LTD was the propshaft, since it needed to be media blasted and setting everything up outside is such a hassle, I elected to also do the radiator support and condenser.

They're pretty grungy.

The propshaft was pretty straight forward. New cardan joints were installed and checked to make sure they were smooth after pressing.

Next up was the dreaded exhaust system. What I wanted was a cross over and 2.5 in exhaust all the way out the back and most importantly I want it as quiet and free flowing as I can make it with available mufflers and resonators.

For the mufflers I bought the Walker Quiet Flow series, which sadly isn't that quiet as I have these on my Caprice Classic with its 454. But they seem to be the quietest in my search for least resistance to flow. It always comes down to a compromise.

The next part was trying to figure out the best place to locate the muffler. Since this car was a single exhaust car I only had one set of hangers, which means I'd have to make my own as the Ford ones are discontinued. For the exhaust pipes others have suggested and used GM 'A' body prebent exhaust pipes. I will say they are really close and in a pinch could work, but they needed some adjustment.

Once I had the best location of the muffler sussed out I started on the main pipe to connect the engine to the mufflers.

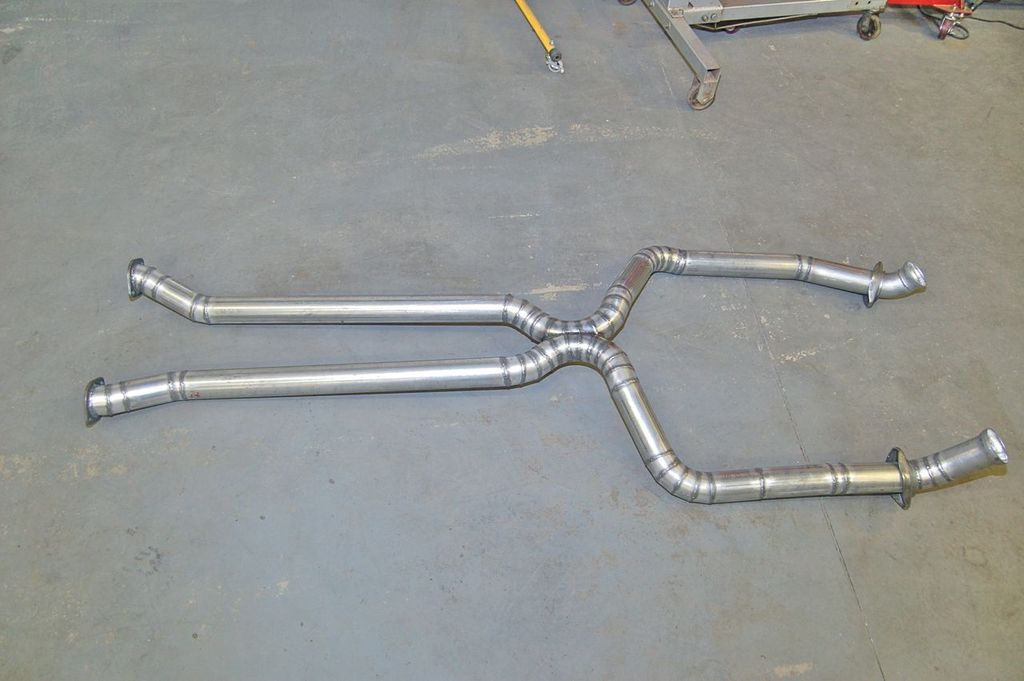

First thing I did was to make the cross over from scratch. The problem with a '66 is that the E-brake mechanism is right under the C6 tail housing, which means there isn't much room for exhaust sandwiched. A standard (off the shelf) 'X' pipe wouldn't work. I needed one that was smaller and tighter fitting.

So I made my own with the necessary curves.

This should lend to side balancing as well as a unique sound.

I had finished contriving the fitment from the FPA FE headers to the crossover.

In order to complete the rest of it it was necessary to temporarily bolt the body back on the frame and measure off the floor and trunk pans.

There's the completed main section. As I have an unnatural distaste for crushing pipe clamps and I also wanted the entire exhaust to easily bolt in and unbolt out, I welded flanges on the mufflers and the conjoining pipes. The only clamps used were to secure the pipes to the hangers and not really crush anything.

The replacement fuel tank was also temporarily installed and the rear GM 'A' body pipes were adjusted to give a better fit. Well when I say adjusted I mean cut and welded.

You can see how there isn't much room for the exhaust in between the E brakes and the C6 and propshaft. I do not think Ford ever intended this setup on their '66 design. Fortunately by 1968 the E-brakes were moved over to the side of the frame and that car will be much easier.

Here's pic of the car temporarily bolted together. Such a far cry from the original pics.

One of the last welding bits were to add the bungs for the o2 sensors and the evacuation ports.

And also add resonators to help quiet things down out the back. Since I only had one side hangers I remade both rear tail pipe hangers in the Ford style from scratch so they match, plus the rubber material was falling apart on the original.

For the rear hangers the Ford OE hangers were too cumbersome so I tore a page from my '73 Caprice Classic and since the receiver portion of the hangers are still being made I bought those and made a custom set of GM like slide hooks but have these so they bolt in the Ford threaded holes in the frame.

They are more compact and easier to hang or remove the exhaust than the OE style main hangers.

I still need to powder coat the hangers, switch out the rubber material on the rear tail pipe hangers as the durometer is too low and it's a little softer than I'd like. So I bought a sheet of rubber with a higher durometer. Then ceramic coat the entire exhaust portion I made including the mufflers. The headers are already ceramic coated inside and out for temperature insulation.

Next post is plumbing on the chassis.

Cheers.

Click here to continue to part 25