1966 Ford LTD Resto-Mod : 027 Transmission Oil Cooler Lines

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65Running the Transmission Oil Cooler Lines

Time to crack on with the '66 LTD, I have an assemblage of items for coolers that have to be run eventually, but I'll start with the transmission oil cooler lines to the first cooler for now.

In the picture I have some used coolers I pillaged from a yard. They are stacked OEM coolers from a police car. The stacked coolers offer less resistance to oil flow.

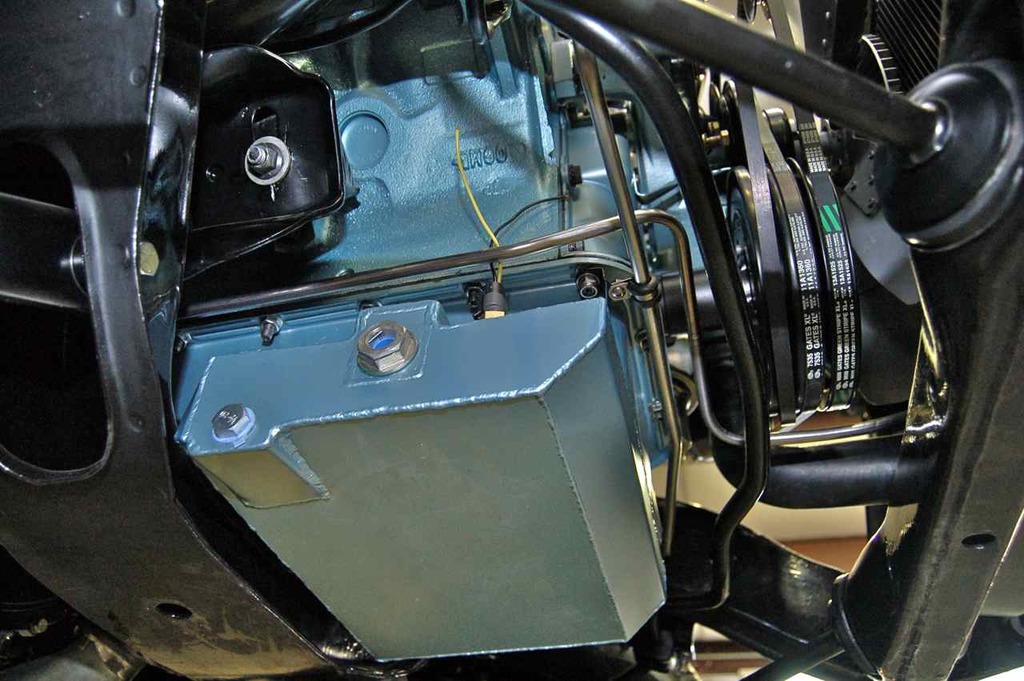

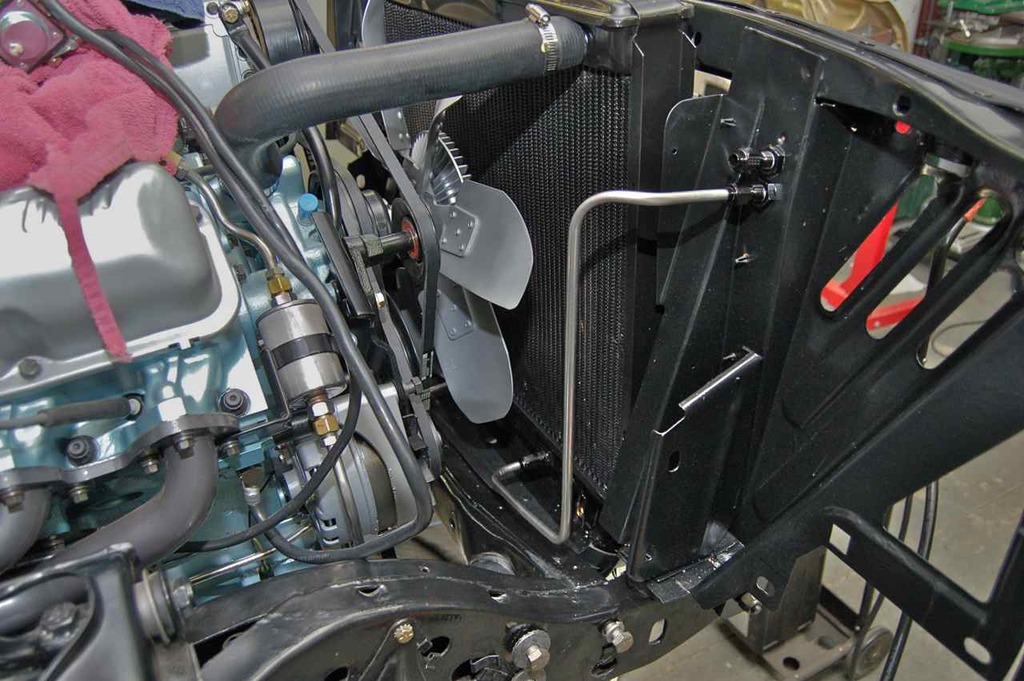

The cooler on the right will be for engine oil and the cooler on the left will be the ancillary trans cooler. The transmission oil will first circulate through the standard one in the radiator. I opted for the heavy duty cooler as well as passing fluid between two of them because this is still the C6 with no lockup and if the extra horsepower is utilized the customary 9/10 lockup speed on the converter will still yield much heat in slip and that needs to be dissipated for transmission life. I also opted to install a transmission oil temperature sensor on the outlet.

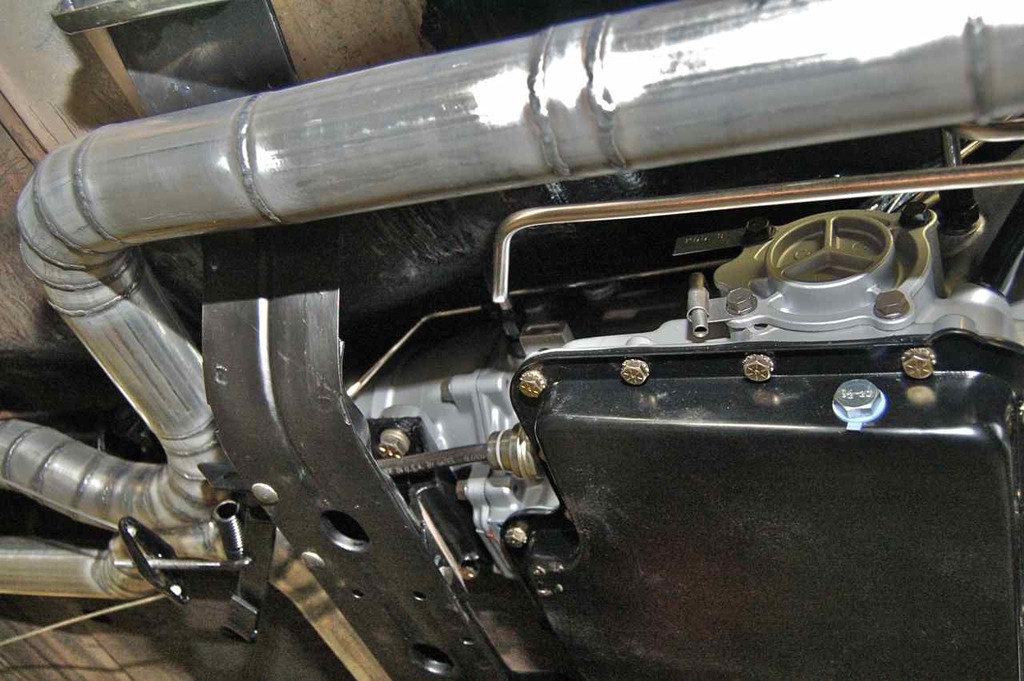

As a last note I wanted to use AN fittings, because one, they are easier to flare than double SAE inverted flares and two, they look nicer. With that I purchased some 3/8" stainless line and even though the hard-line to AN adapters say use aluminum line only, I have read in a few places that others have been able to use stainless with these fittings as long as the flare is done well. I think we can handle that and we'll give it a go.

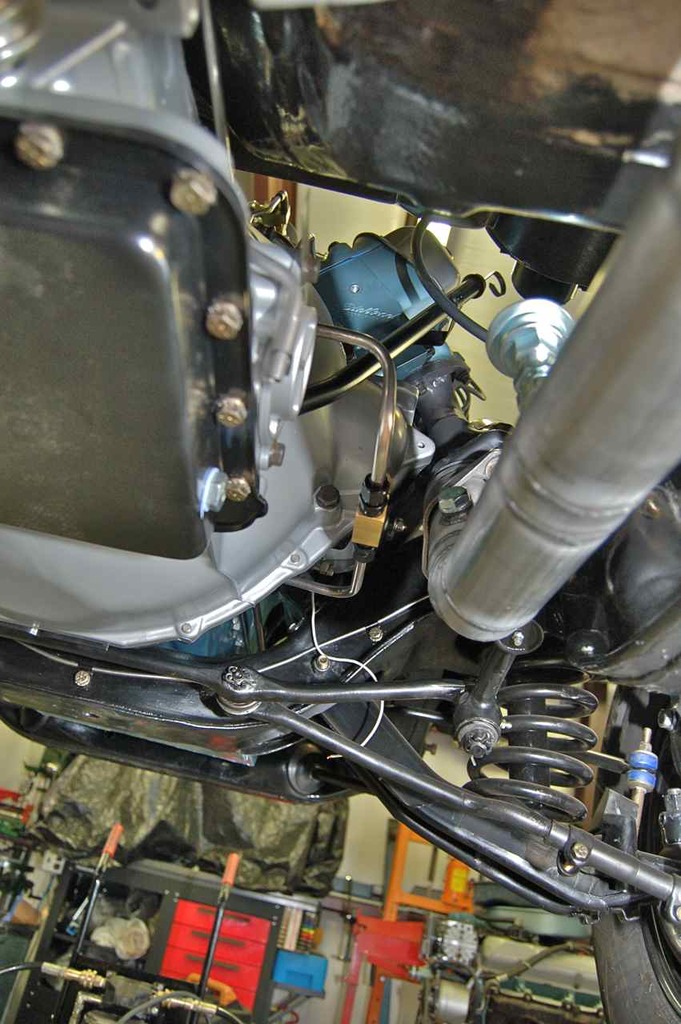

First up was the transmission adapters, most forums say you can use a 1/4 in NPT fitting. Which will work but technically isn't true. What is needed is a 1/4 in NPSM (straight thread, not a taper). I bought these for the GM series transmission, they were a little tight at the beginning but I ran them through a die and they fit much better in the C6 and snugged up to the case. I added an Oring along with their Teflon seals for good measure.

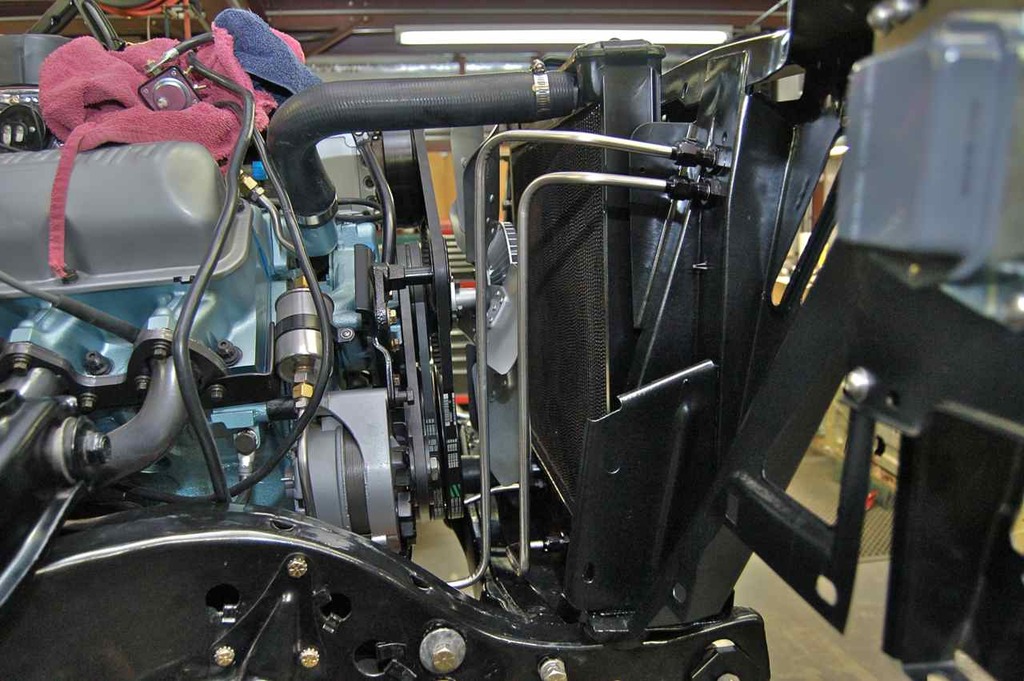

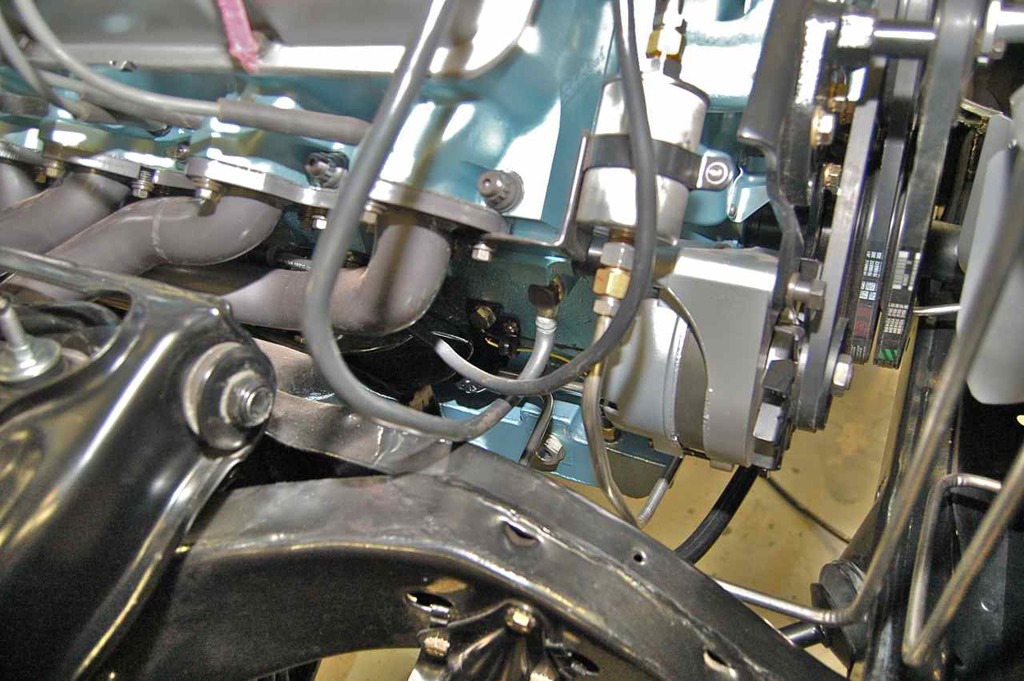

After mounting the transmission oil temp sender, which was a 3/8 in NPT brass Tee with a GM coolant sensor and AN fittings, the next step was contriving a line from that to the cooler in the radiator.

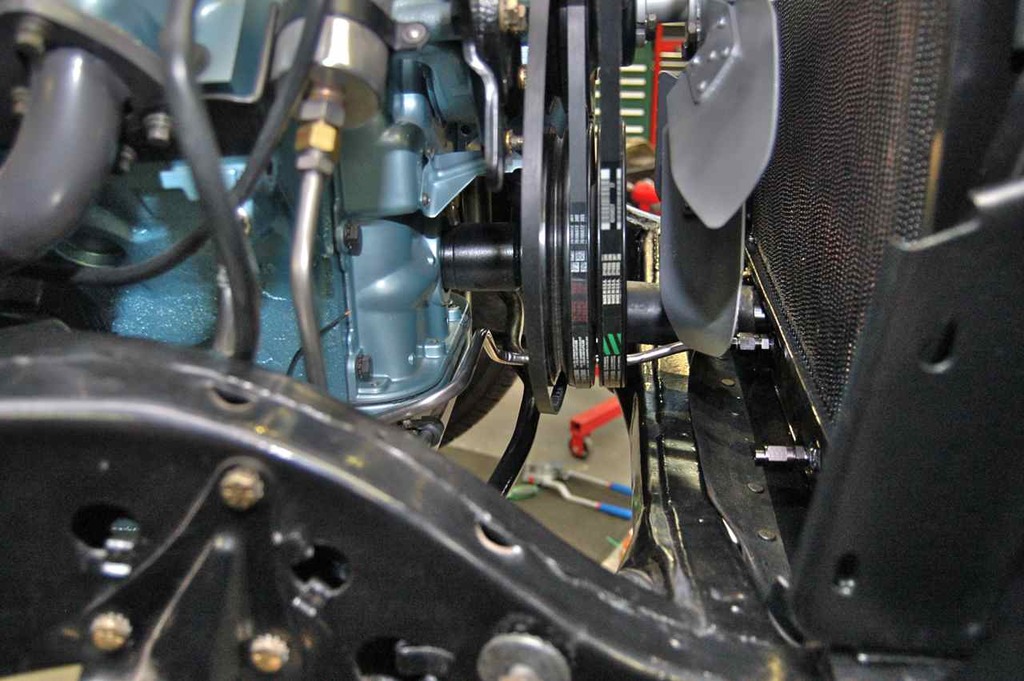

Because the lines have to run between the engine and chassis, in order to get a good idea of where or how to start bending I used a piece of 10 gauge solid electrical wire. It's still enough to hold it's own after shaping in place. Then I bought a cheap steel line and bent that based off the wire, then once that was tweaked I copied that onto the stainless line.

I had to remove the alternator but it did snake in just fine after that.

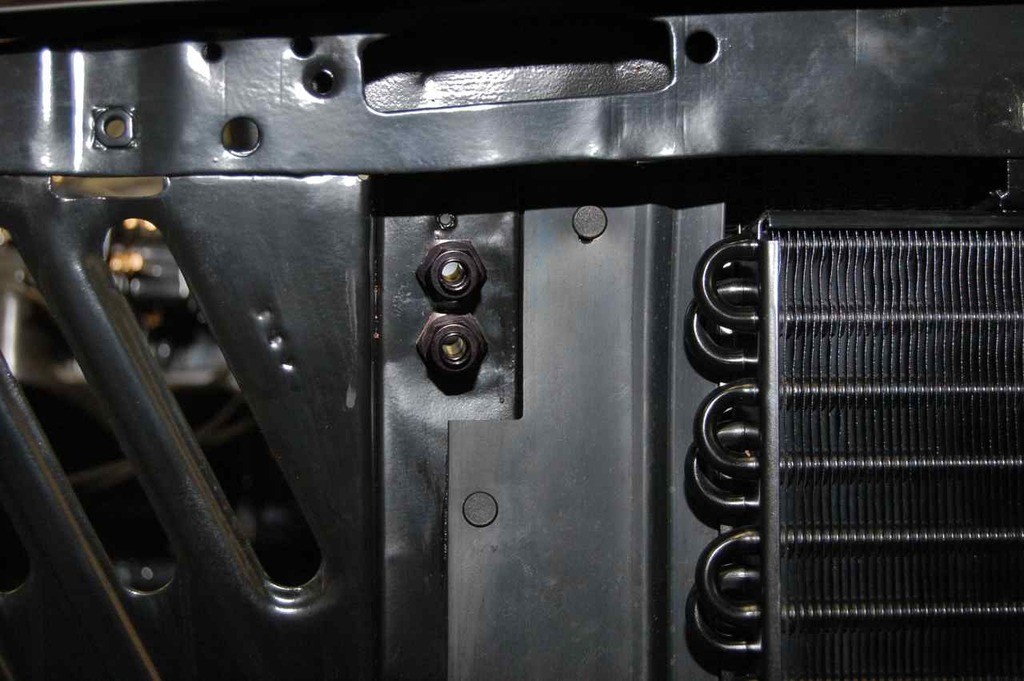

The ancillary oil cooler for trans oil will be sandwiched between the grill and the condenser or part of it. So I installed these bulkhead fittings as the pass through.

Using this '66 galaxie 500 XL as a guide since they share the same grill as the LTD the ancillary oil cooler will go here.

Using the same technique for the first line I made the connecting line to the bulkhead fitting.

And again for the return line back to the rear of the C6 for cool oil lube.

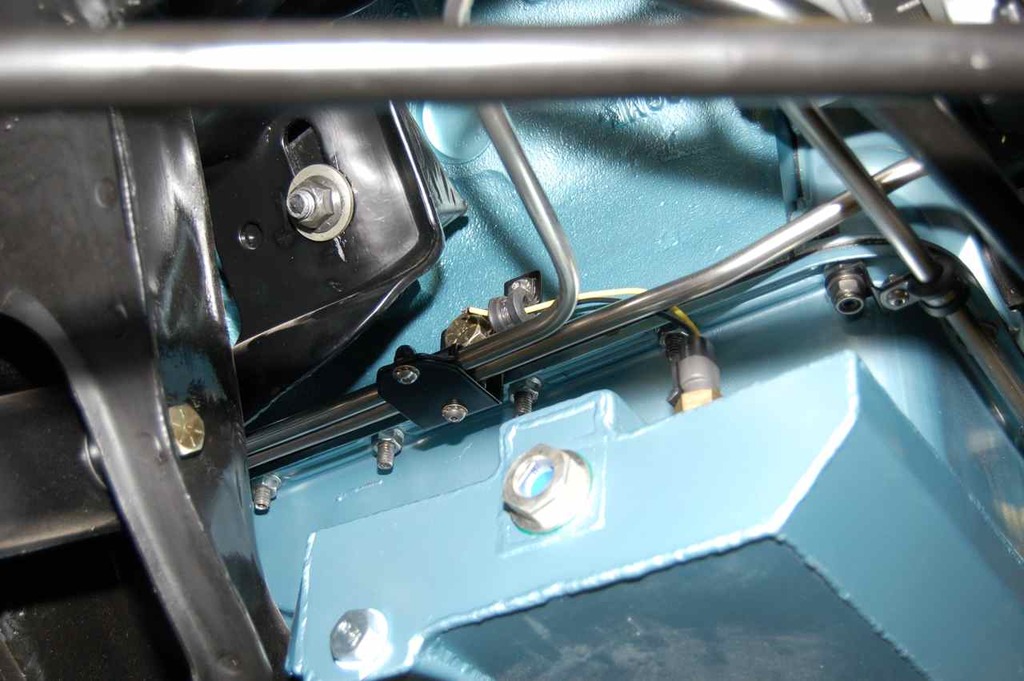

I made both lines couple here for two reasons, first there was no way to snake these lines in otherwise. Secondly the plan is to install a modern 4R70W at a later date. I can just remake the short sections that connect here to the new transmission rather than having to redo the whole lines. And as mentioned before the top connector is the Tee with the temperature sensor in it.

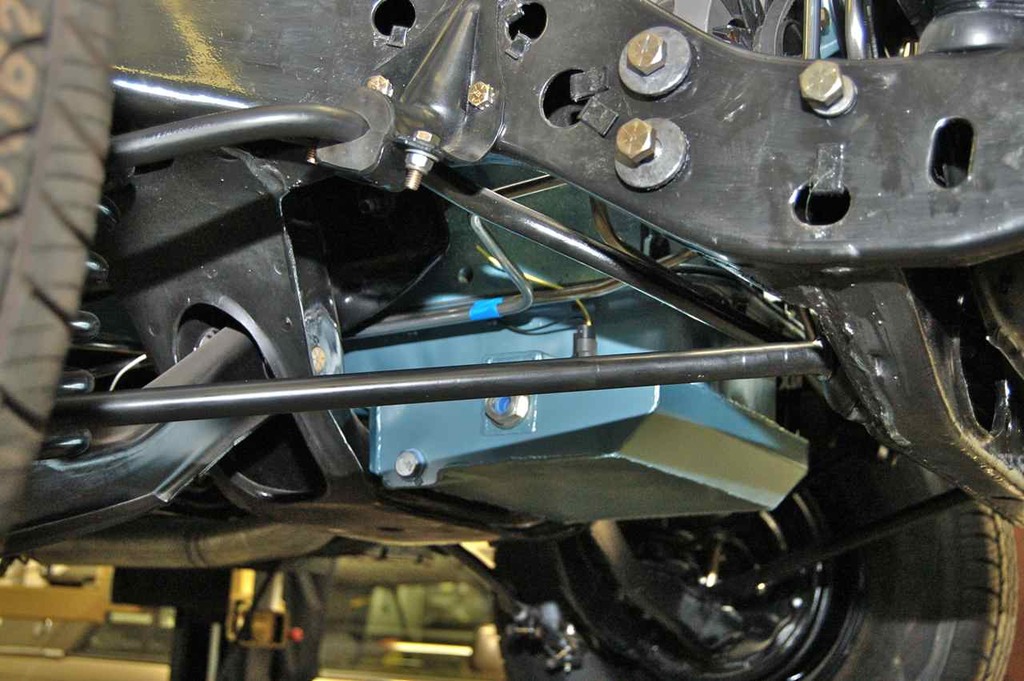

However I needed something to hold the lines, after all what would the neighbors say .

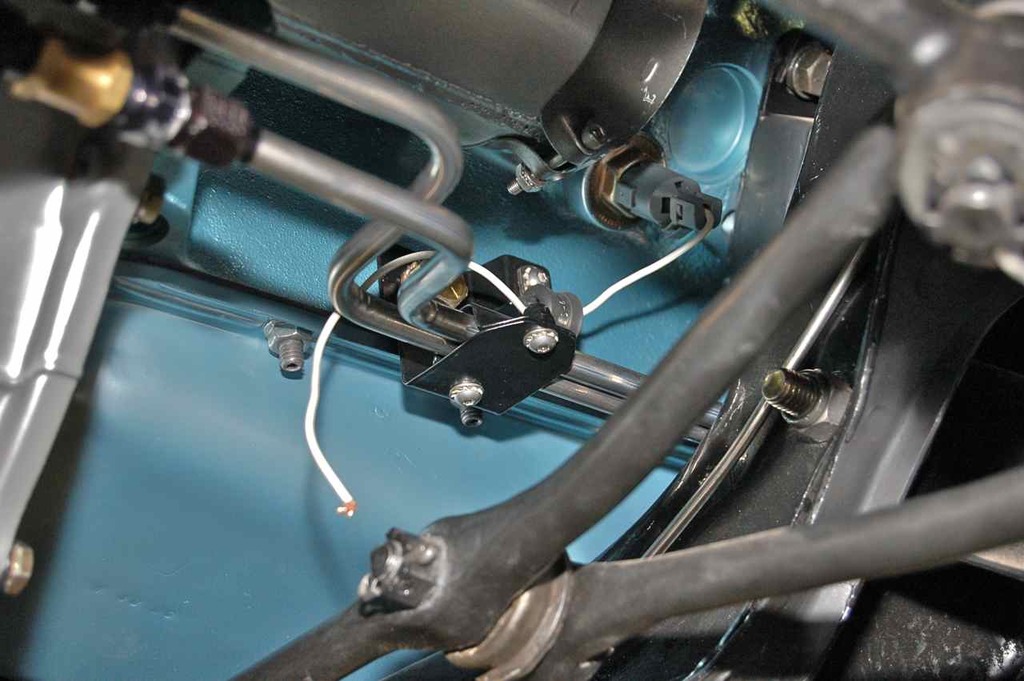

I came up with this after some thought, I also wanted something to hold the sensor wiring harness in place as I didn't want to run it up with the alternator wiring. The fast switching and decent current draw of the field for the alternator couple couple inductively to the sensor wires if ran in parallel. Especially to higher impedance sensors such as the O2 and the like.

I made two of them and they screw in to the vacant holes on the lower side of the block.

I applied extra powder coat since they were on the bottom near road debris.

Looks interesting next to the Mad Max oil pan

They hold the cooler lines nicely and I also have a place to run my lower wiring harness.

I know it doesn't look like much work, but it was probably 3 days spaced out worth of work.

At this point I'm done with the chassis until the body is ready to be bolted to it for the last time.

Cheers.

Click here to continue to part 28