1966 Ford LTD Resto-Mod : 061 Roof Repair - part 2

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65Roof Repair Continued

This one is next.

The patch was held in place by some Clecos. Now I did screw up and removed too much metal from the roof skin as the gap was a bit wide at the top.

Fortunately the MIG welder and I have become really good friends over the years and can deal with that with no problems.

First round of blending. I had a low spot in the lower section.

I reworked it, but still had a dew low dimples, then I remembered why am I even bothering, first the vinyl top will hide slight imperfections anyway, and secondly I am going to try to lead that seam so I can just put a little lead in the low spotted area to calm the OCD.

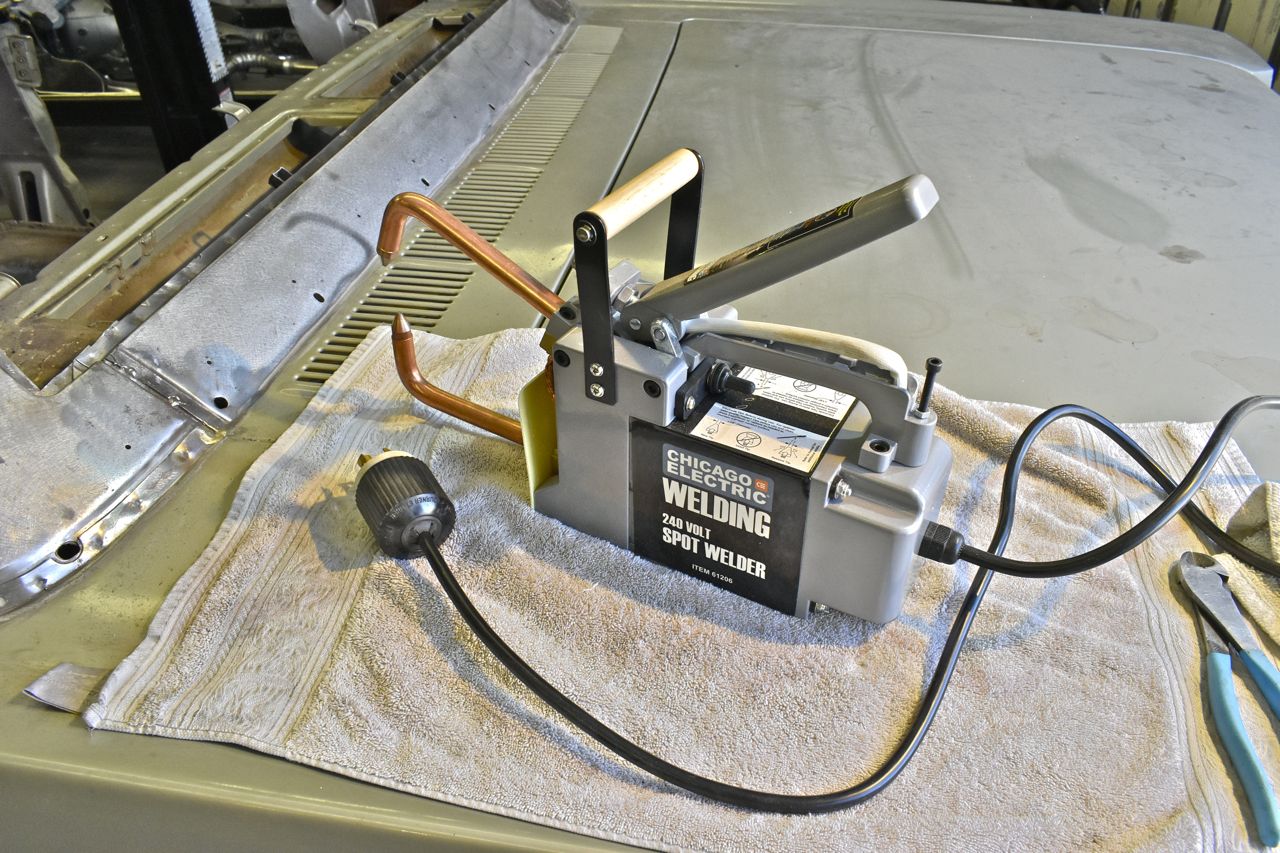

I had to resistance weld the flat section of the flange together so I used the Harbor Freight thingy. Damn this spot welder is heavy. I got lucky and it was an open box item and the checkout girl basically sold it to me for 50% off. It actually does the job.

The only bit left was to install the peg for the trim.

I bought the attachment for this machine that welds those on. I bought a bag of 100 of them and did some practicing.

Did some experiments with scrap first. You can't adjust the current as it's fixed, but you can adjust the weld time. I think this machine puts out 3500 Amperes. I turned up the time and it just melted the little peg.

2 is the magic number for this job.

I measured off the other side and installed the peg.

This side is done, for the little pits elsewhere I just plan to lead those in and smooth out.

Still have 18 million staple and nail holes to fill and grind.

Damn it Ford... your pissing me off with this nonsense.

I still have to do this side, but after tackling the other side I feel a bit more confident now. Don't get me wrong, this is truly the hideous side of the project and it will probably take a couple of long days to complete. Took me 10 bloody hours to do two small patches on the other side.

I did just about patch all the staple and nail holes, have a couple to redo as this is not an easy area to on. At least the windscreen was big enough to stand up in and work. This rear window is very difficult to work on in the middle.

That's it for now.

Until next time.

Cheers

Click here to continue to part 62