1966 Ford LTD Resto-Mod : 056 AC Idler Belt Pulley w. Replaceable Bearing CA Thermactor Emission

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65Hello all,

If I haven't bored anyone to death yet with the boring exhaust post, this one should surely put you to sleep. This is another item on the niggle list that I had to revisit to sort out. The A/C idler belt idler pulley.

A while back I had adapted new off the shelf pulleys for the tensioner and idler since no one makes these and who in their right mind would try to use 50 year old bearings with 50 year old grease, or what's left of it in there. So using NOS isn't even an option really.

The problem arose from using the only pulley at the time I could find for the 17 series belt (1/2") and those were made by Gates. The main deviation was the pulley is a tad smaller in diameter than the original Ford. I have a post earlier in this thread about converting the idler and tensioner to this pulley. Well the tensioner pulley works just fine, but the belt on the idler side (pulling side on the crankshaft) oscillates. At a certain RPM the belt goes into resonance and starts slapping the smaller Gates pulley and makes a racket out of the bearing. Not a good sound.

Here's a video clip of that happening, now it actually does it with the A/C engaged or not engaged, which to me is the damnedest thing.

I had to find a correct diameter pulley. Well by happenstance, one of our field find '66 galaxies with factory air con and FE came with the California Thermactor emission system (air pump) and as a result has a different front engine dress setup than the really common (other 49 states) Imco emissions for '66.

The common Imco system with FE and air con use idler and tensioner pulleys with complete oddball, half English - half metric elongated bearings. They were made by Federal but no one makes those anymore. Plus those assemblies were more or less press together forever deals and disposable.

Oddly the '66 thermactor tensioner pulley was a billet machined pulley with a replaceable bearing. Now the bearing is still a metric mutant for the 1966 American automotive industry, but is still available and the pulley is the right diameter and for a 17 series belt.

However I only have one of these pulleys, it's enough to sort out the '66 LTD, but it's the other galaxies I'm wondering about.

Here's the Thermactor pulley and new bearing, it has a nice inside snap ring to retain it and that pulley is one solid chunk of steel.

Below is the pulley power coated and assembled. I have to make an adapter to press into the original cast iron base that I can screw this pulley into. So on the right is a stock bar of 4130 Chromoly that is 3/4 hard. Just easy enough to machine and still hard enough for this use without needing to send it out for a full hard heat treat.

Next I need to separate the old pulley from the cast iron base (this is another spare I have laying around)

So here's the mutant one piece bearing pulley deal separated from the base.

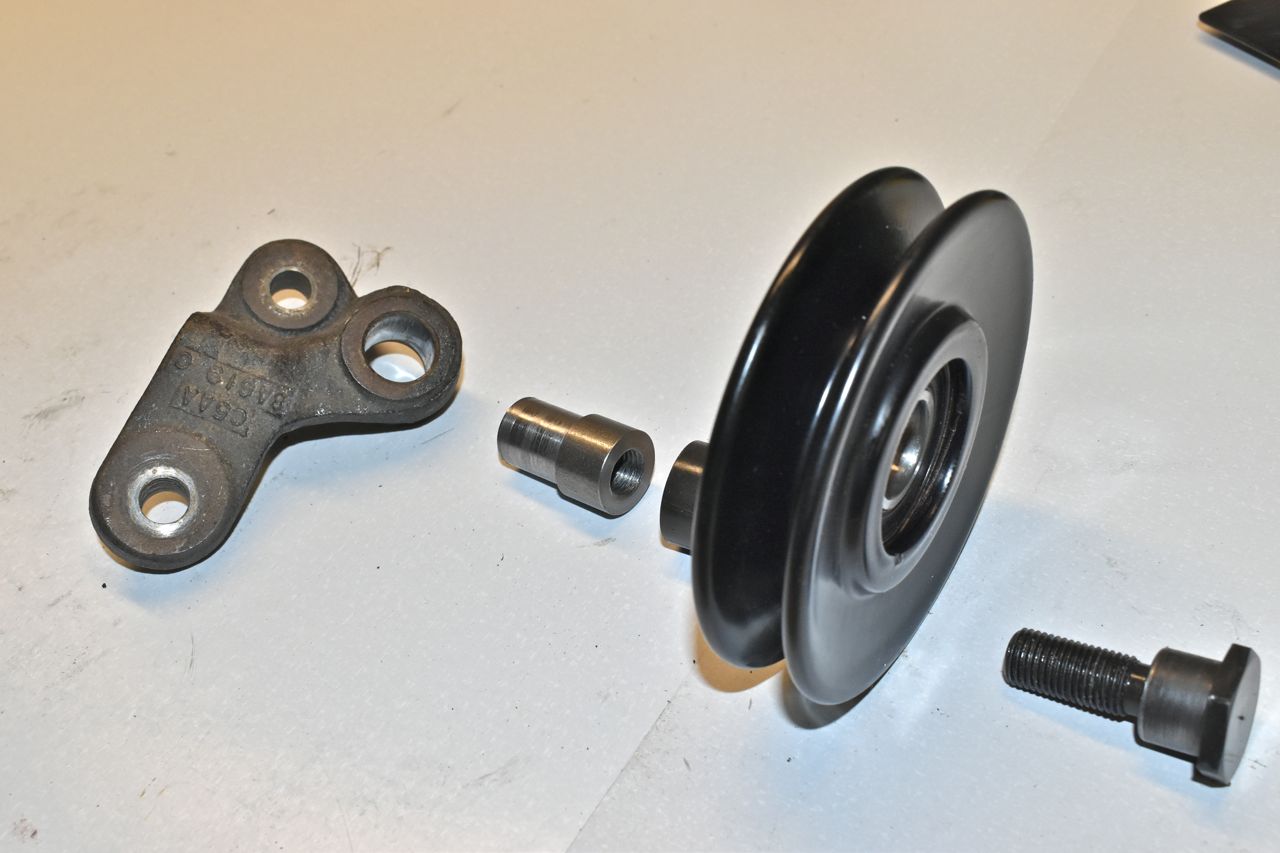

Here's the part stack up for reassembly. I measured the height of the pulley and where it needed to be then made a quick sketch of how much to machine the 4130 to obtain that. You can see the little adapter. It presses into the cast base and has the threads in it for the bolt. That bolt is 7/16-20 English with a metric cut shoulder for the bearing. Thank you Ford for that abortion.

Next is clean the base and press in the machined adapter.

Powder coated the base and assemble.

Here's the new old pulley next to the newer one I had previously done. There is only a 1/4" difference in radius, but in this case it makes all the difference.

Here's a link to the video with the new old pulley installed. The belt slap is eliminated, but notice how oddly the belt behaves between the idler pulley and the crank shaft pulley. No wonder why Ford spent money on putting an idler in this location.

I have tried to search the MPC high and low to find a Ford part number for that 1966 only Thermactor pulley and I cannot find it, not even in the illustrated portion. I guess when it comes time for the other galaxies I'm going to have to pull this pulley off and take it to some of the local machine shops and see how much it would cost to have a handful of these made.

Hope this wasn't too boring, but another one checked off the list.

Rant 1

I don't think it was a question of Fords early systems being inefficient. The 3rd gen factory air con is just a nightmare engineering and maintenance wise. There's no blend door in these systems and no way to get dehumidified hot air to the defrosters for the windscreen like you can get with just about any other factory HVAC system. The heating and cooling thermostats and controls are dubious at best on 3rd gens. Even with that said, once the system has been rebuilt it does blow ice cold and heat works really well, but you have to stay atop of the system and care for it, especially the heater for everything to work as it should.

There's nothing wrong with the York, it's ok, a little more pronounced pulses due to two large cylinders instead of the A6's smaller double piston 3 cylinders but otherwise a bullet proof compressor as long as there is oil in them.

Rant 2

I do not need the part number for the '65-'66 Imco equipped full size, FE with factory A/C idler pulley. I already know that's long gone obsolete. What I was looking for was the part number for the pulley that I integrated onto the old idler base. That pulley was from a '66 full size (actual car was a std galaxie 500 with 352 and air) with Thermactor, FE and A/C. That pulley if I remember correctly was mounted above the coolant pump and between the air pump and A/C on a large (spanned the entire front of the engine) bracket. That's the one I couldn't find any reference too in the MPC. I have a vein hope with that pulley in that it would be used in something else that still might be available as it has a replaceable bearing.

Rant 3

I think this is going to be a dead end. That California only emissions pulley I used is probably unbelievably rare. Looks I'll have to use plan B in having a machine shop make a handful of billet pulleys like the California only pulley.

Rant 4

This pulley. This is the California 1966 pulley used for full size, at least, with air pumps. It's a billet pulley from Ford and it screws onto a massive plate in front of the FE.

Rant 5

The MPC does show the standard 49 state Imco belt/pulley arrangement. Finding the part number and the illustrations for what the LTD came with is no problem. Finding the thermactor system pulley was just a shot in the dark. I tossed all the 1966 thermactor stuff, sans this pulley, from the one '66 galaxie 500 that was from California, so I do not have any pictures of those parts.

My best bet will be just having several of these California only pulleys made up locally and that way I can retrofit all the common Imco system pulleys for the A/C belt thereafter. Like I mentioned no one makes the common Imco system idler or tensioner pulleys for the '65-'66 A/C belt anymore and who would use a pulley with a 50 year old bearing with 50 year old grease.

Rant 6

They still make the bearing (albeit all metric) for the 1966 California Thermactor equipped FE's with A/C pulley. The whole problem with the '65-'66 Imco equipped FE (every other galaxie) is that the pulleys are not rebuildable/serviceable. This is compounded by the fact that aftermarket generic pulleys for 17 series belts are smaller than the Ford 3.75" diameter pulley. The idler needs to be at least this big in diameter. Bigger will work too.

Hence the dilemma.

Rant 7

OK so the goal is to have a 3.75" or larger pulley with a replaceable bearing or a source for a new pulley with integrated bearing of that same diameter. I can't use any of the old or NOS pulleys because all the lube is 50+ years old, regardless if the old pulley bearing still feels fine or not. One must keep in mind our old cars are driven on a daily basis, old cruddy bearings will not last.

That's whole reason why I used the 1966 California only idler pulley, it had a replaceable bearing, of which is easy to get. But it's just a pulley, so I had to make an adapter to mount that California pulley (with new bearing) to the old Imco base so I can use it on the Imco equipped cars we have.

Unfortunately there are no numbers on the California only idler pulley. That's the part I had the whacky idea of seeing if Ford used that California only pulley on anything else that I might be able to find more of those pulleys.

Taking the number off the Imco base pulley assembly is only going to pull up more of the same Imco pulleys and those are all non serviceable (throw-a-way) pulleys. I have a box of those already (sigh)

It was a shot in the dark and an unlikely one. What will definitely solve this problem is having a handful of these California pulleys made up as I can buy the bearing and retainer then making a handful of adapters to retrofit the old Imco pulley bases. That way I have a idler pulley with a brand new bearing and do not have to worry about it seizing up whilst on the road.

Cheers

Click here to continue to part 57