1966 Ford Galaxie 500 XL Refurbishment : 028 Engine FE 390 : Cylinder Head Volume Measuring

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74 - 75 - 76 - 77 - 78 - 79 - 80 - 81 - 82 - 83 - 84 - 85 - 86 - 87 - 88 - 89 - 90 - 91 - 92 - 93 - 94 - 95 - 96 - 97 - 98Cylinder Heads

Since aftermarket parts can be a bit dodgy on quality I have been trained (read as having to redo a bunch of work because of poor parts) to check new parts best I can before installing. It's sad when you have play QC on every new and rebuilt part you pay hard earned money for, but alas tis the way things are.

To start I opened the Edlebrock heads and disassembled and oh look what I found. This is why when Edelbrock says "ready to run out of the box" they are indeed full of crap.

This is the first head I opened, the seats are rusty from sitting in a humid environment.

But here's where trouble really lurks. Their single point valve grind isn't concentric. You can see the single lip from the seat fade away as it goes around the valve. Now the previous set of heads I bought suffered the same thing. It was so bad, in fact, when doing the static compression check on the engine not only could you hear the air leaking past the intake valve/seat on some you could actually feel the air flow through the intake.

Now last set of heads I just ponied up for a valve job on already expensive set of brand new heads but this time I opted for just a good ol valve lapping. I know some frown on the idea of valve lapping in modern times, but it's turning out to be 6 of one and half dozen of the other as far as options. If I have to sacrifice a tiny amount of flow around the intake valve in lieu of a lengthy and expensive wait to get these heads back, so be it.

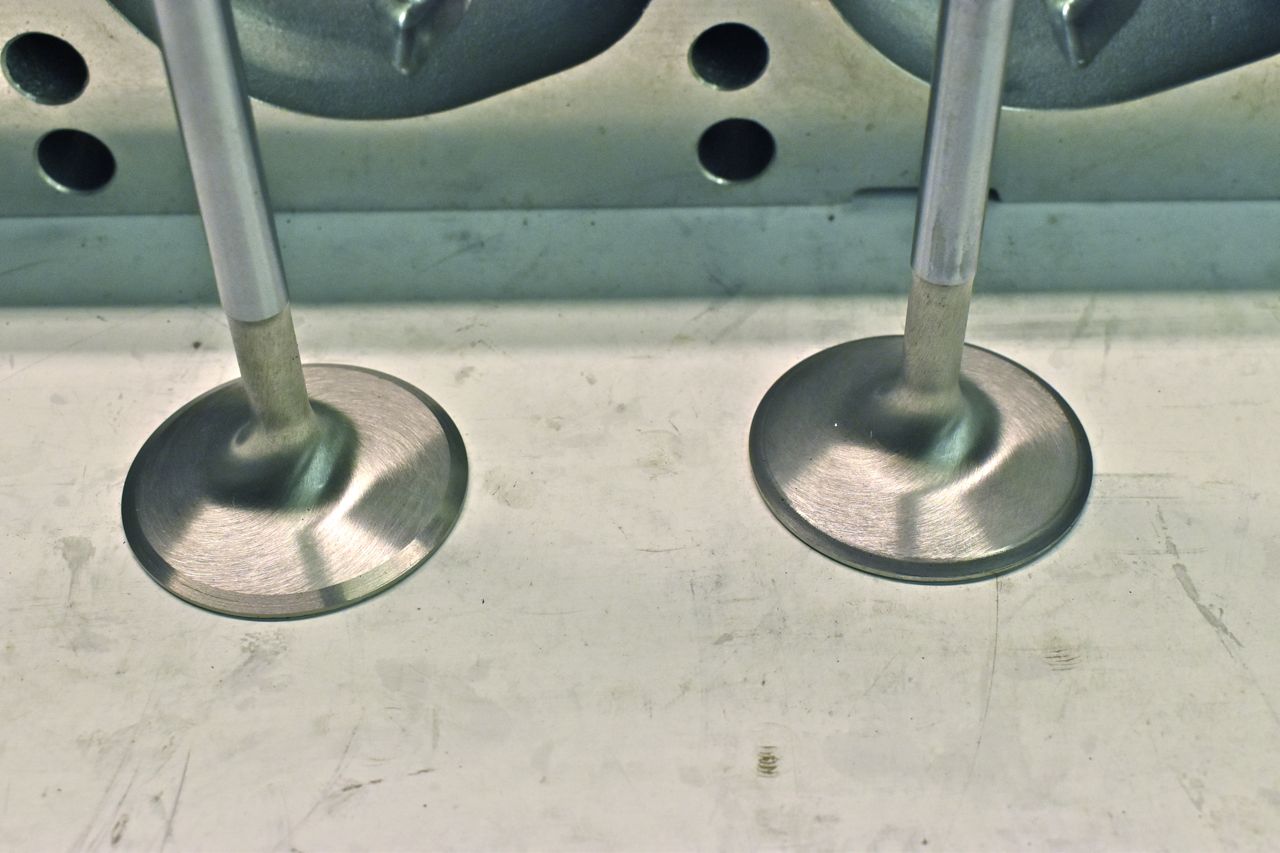

Lapped.

Difference between sealing and non sealing.

It also cleans the rust out of the seats, because you know; quality.

All completed now the valves can seal and I can check the volume of the heads.

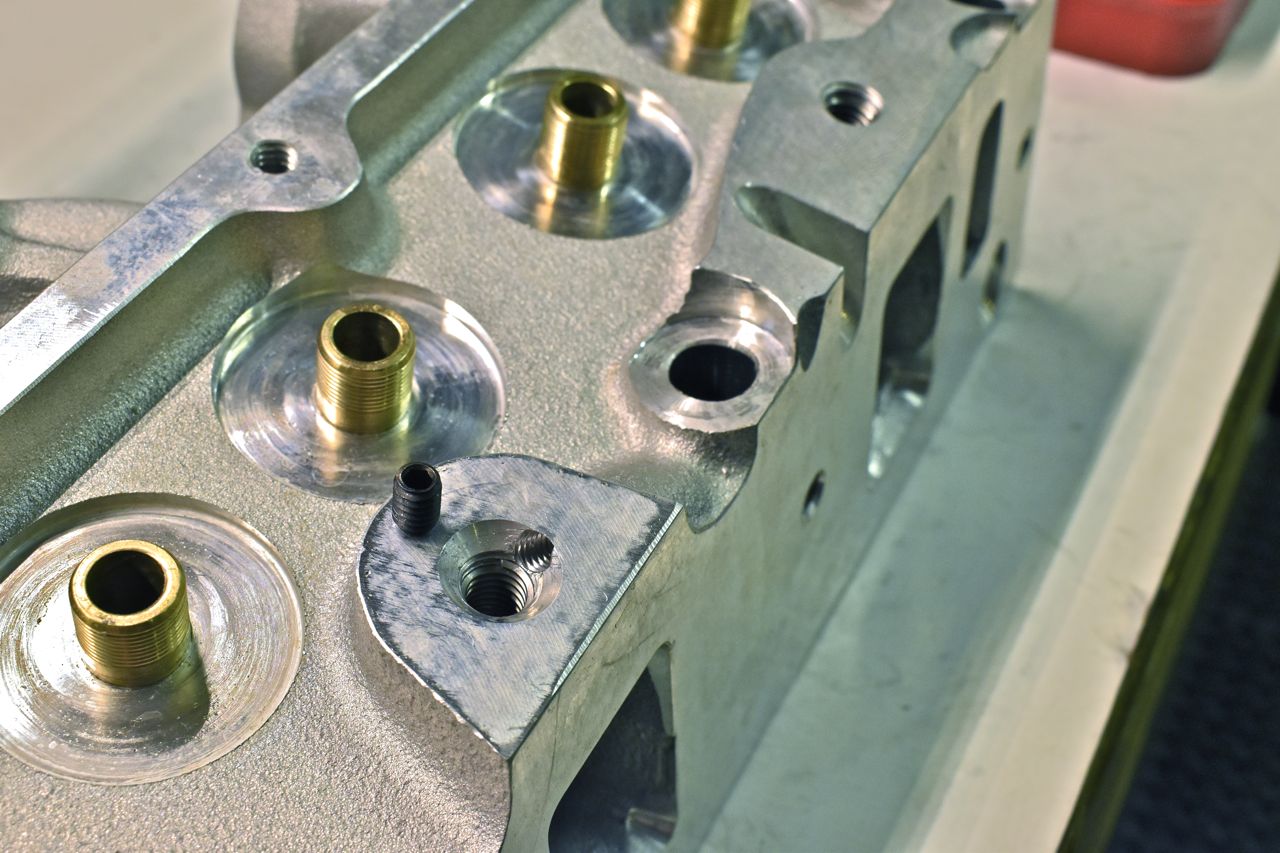

But first I drilled and tapped the oil feed for the rockers and inserted a plug since it will be oiled through the push rods.

Installed with a little Locktite.

Pardon the mess but it's the set up for measuring the volume.

Used Vaseline to act as a mild sealant for the plastic cover.

For those wondering, the fluid is just 91% Isopropyl alcohol and green food colourant.

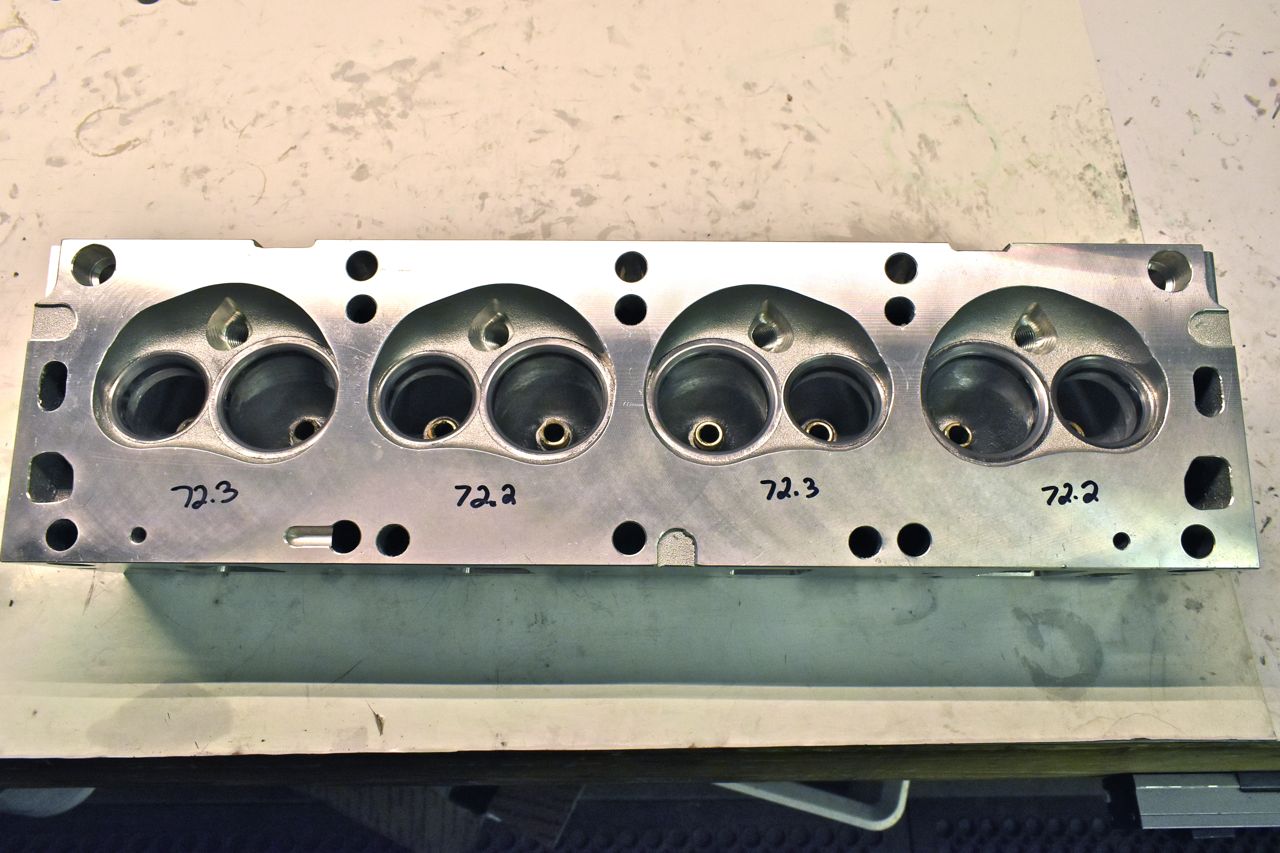

Here's the results, well at least (credit where credit is due) Edelbrock fixed their combustion chamber volume as the last set was out of range of Edelbrocks specification. These are actually in spec. One is a little sloppy and high but still in range.

Agh head number 2 I opened up and disassembled. This little gem was full and I do mean full of metal shavings right from the get go. Way to go Edelbrock QC.....

Unfortunately it did suffer from the intake valve thing and rusty seats as the previous head so it received the same treatment and also had the oil port plugged to the rockers.

This head however was much more consistent on volume though.

With that the heads were reassembled and done with for the moment.

More to come.

Cheers

Click here to continue to part 29