1966 Ford Galaxie 500 XL Refurbishment : 045 3D CAD Design and ABS Printing Lens Housing

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74 - 75 - 76 - 77 - 78 - 79 - 80 - 81 - 82 - 83 - 84 - 85 - 86 - 87 - 88 - 89 - 90 - 91 - 92 - 93 - 94 - 95 - 96 - 97 - 98Hello,

I don't want to go off too far on a tangent but I had to make a plastic part for my ancient strobe wheel balancer and it took loads of time to do.

The original broken and melted front face is obviously on the right and my prototype is on the left.

I can't find anything for this wheel balancer anymore. I think they are just about extinct so I have to make my own. This is where I can appreciate the amount of time and money that Edelbrock spent on the intake. I just just had to make one plastic part from scratch and it took me about 30 man hours.

That includes the initial measuring best I could based off the old part, modeling it, printing the first one, seeing where it was still off, correct the 3D model, reprint, sand, paint and install.

Sure it's a 3D printed ABS part and it will never be as nice as the injection molded part, but it's a darn sight better than the old part.

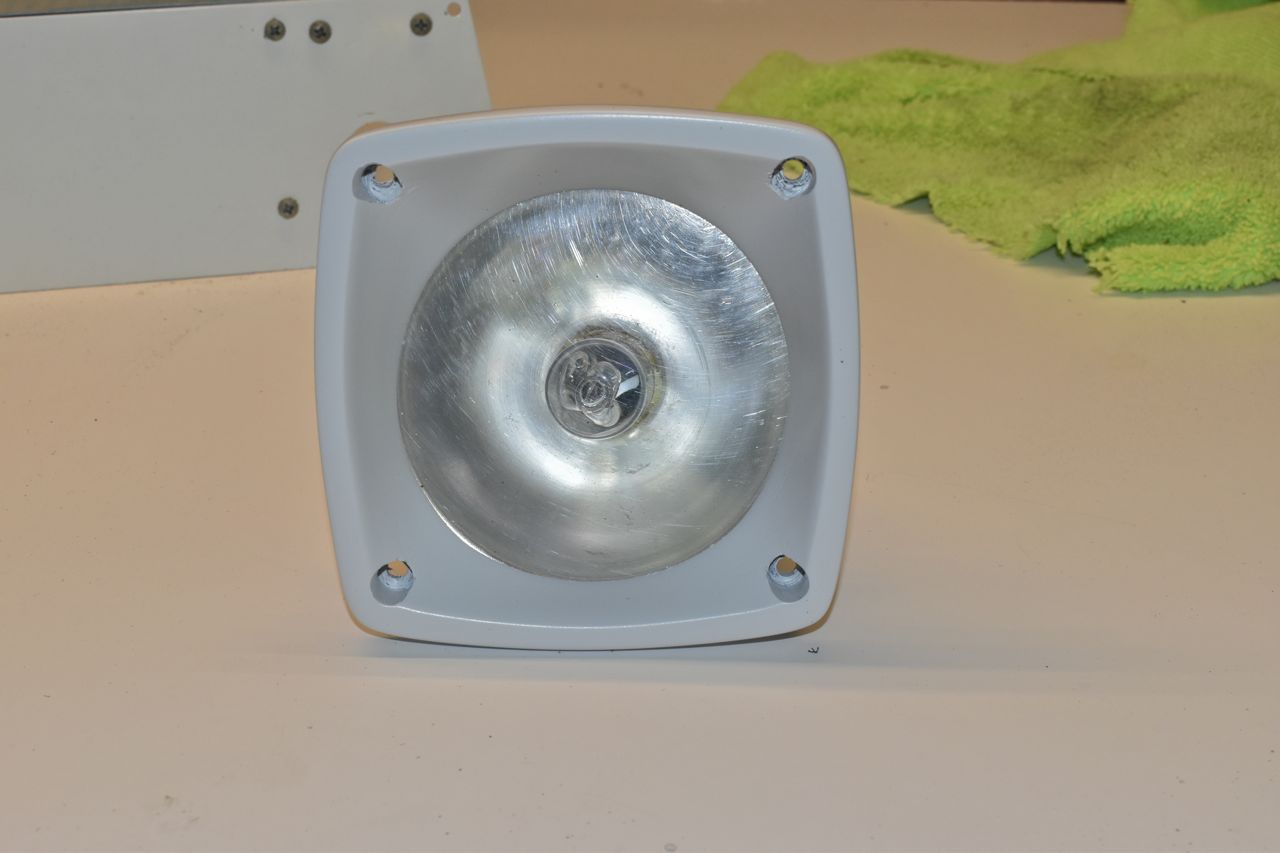

Test fitting the lens and strobe housing.

fits like a glove

All that work just to make the strobe a little bit nicer. Plus I went through the electronics and found some high ESR caps that were also electrically leaky. This should work for another 50 years.

Cheers,

Click here to continue to part 46