1966 Ford Galaxie 500 XL Refurbishment : 079 Evaporator & Blower Motor Plenum, pt 3 : Bench Test

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74 - 75 - 76 - 77 - 78 - 79 - 80 - 81 - 82 - 83 - 84 - 85 - 86 - 87 - 88 - 89 - 90 - 91 - 92 - 93 - 94 - 95 - 96 - 97 - 98The Evaporator / Blower Motor Plenum Part 3

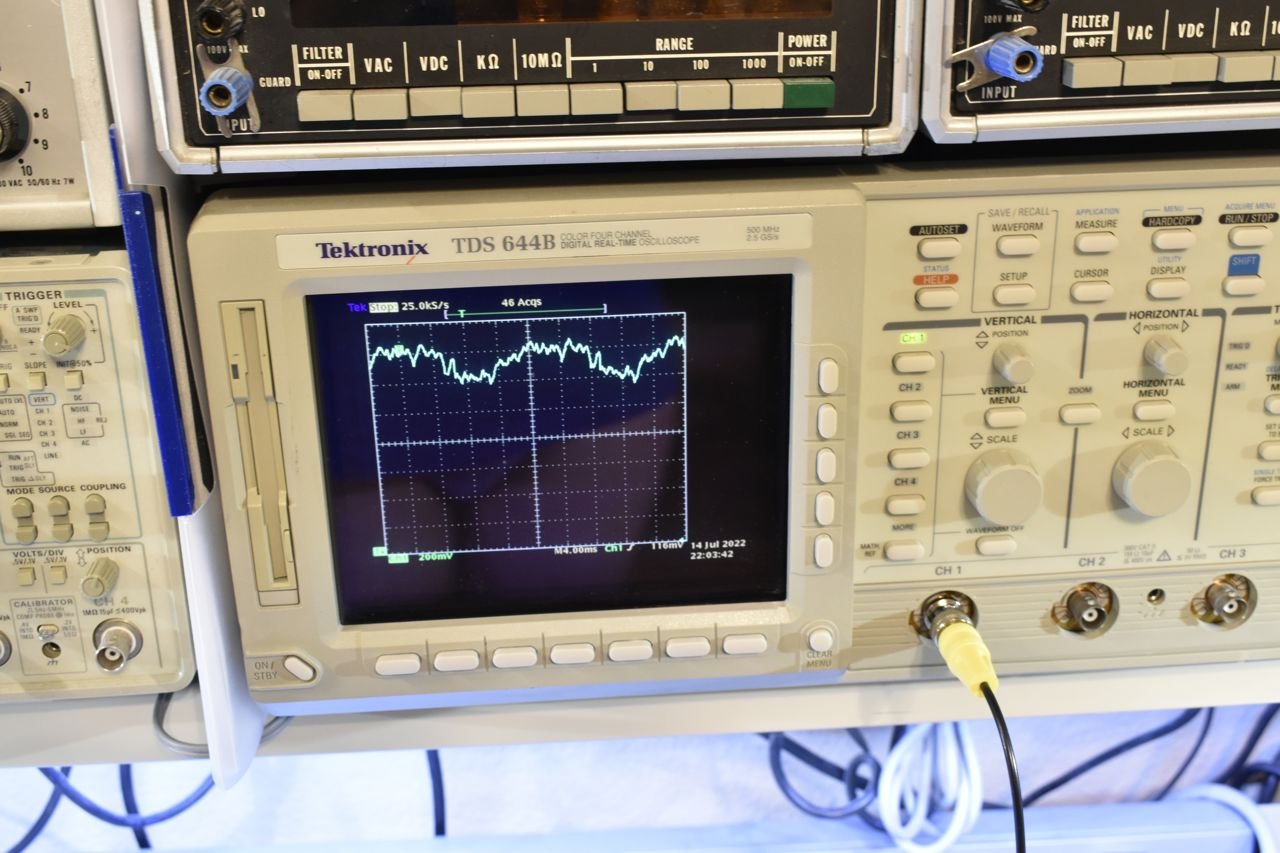

Here you can see the brushes cutting across the contacts on the armature. The current isn't perfectly matched on all the windings but for a 56 year old automotive motor it's doing just fine. You can see the pattern repeat and there is about two full patterns on the screen. So this is showing nearly 2 full revolutions of the armature.

Taking the motor to maximum it'll see in the car with the alternator running.

It sped up more and it's cruising. There is one outlier winding drawing around 30% more energy, but nothing to worry about. This motor is ok to put back into service and seems happy.

Now lets check Fillet Mignon.

It's drawing 1.5 amps more than its cooler sibling. So either the armature has shorted turns and or the magnets are now weaker.

Eew. It's spinning just as fast as the better motor but that commutator current is messy. There's no clean current pulses. This suggests excessive arcing.

Cranking it up. It's now drawing 2.2 amps more than the non cooked motor.

Just more the same messy signal. So what's the moral of the story here. The cooked motor has problems, but it does work. It would make a good temporary spare but probably would have a short life if put back into full time service. The important factor here is knowing what you have in a part.

Moving on...

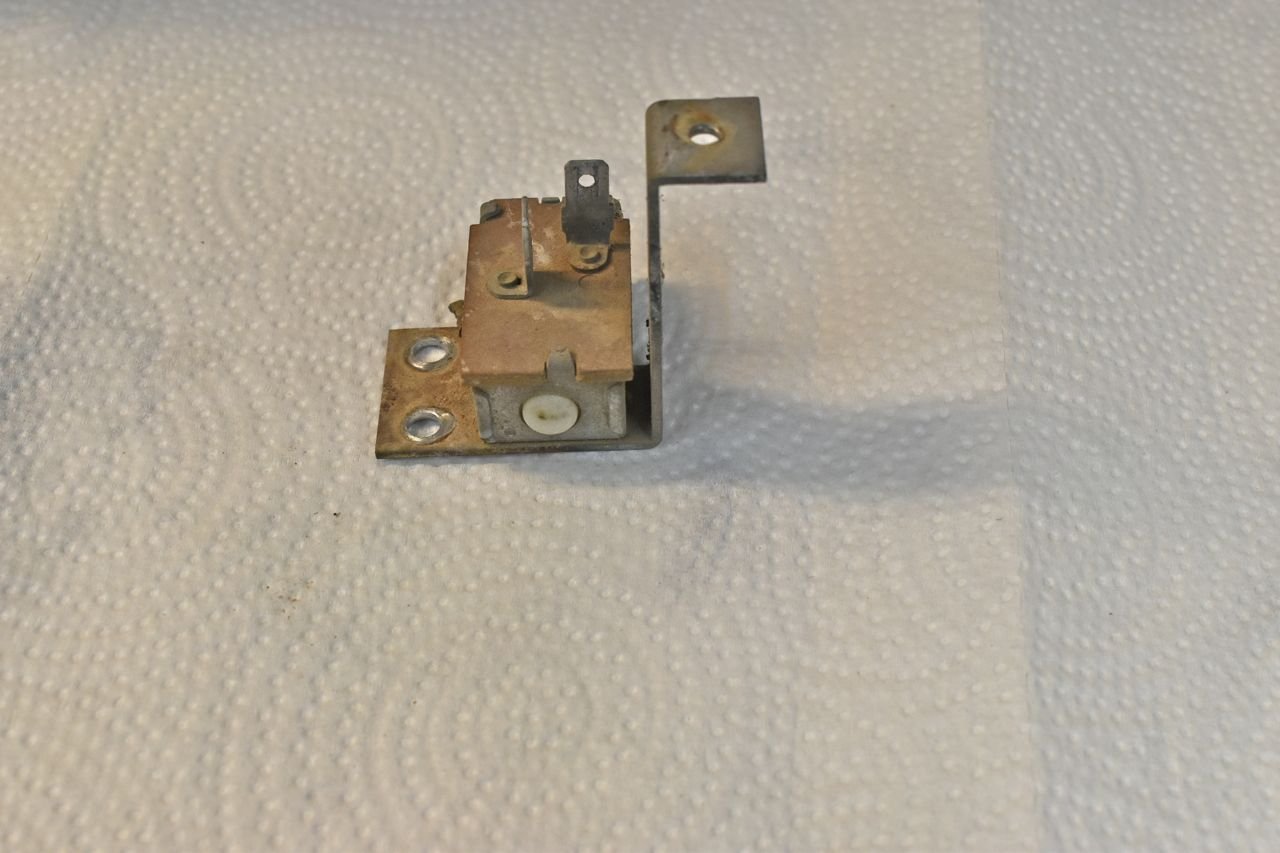

This is the mode door switch atop the plenum. It's job to turn off power to the compressor clutch in any heat mode; floor or defrost. This switch is spring loaded so the plunger is always pushed out. This one, well not so much, so lets dig into this one.

The most common problem with these is foreign contamination and dried up lubrication. These switches aren't reproduced so it's either find NOS or fix your old one.

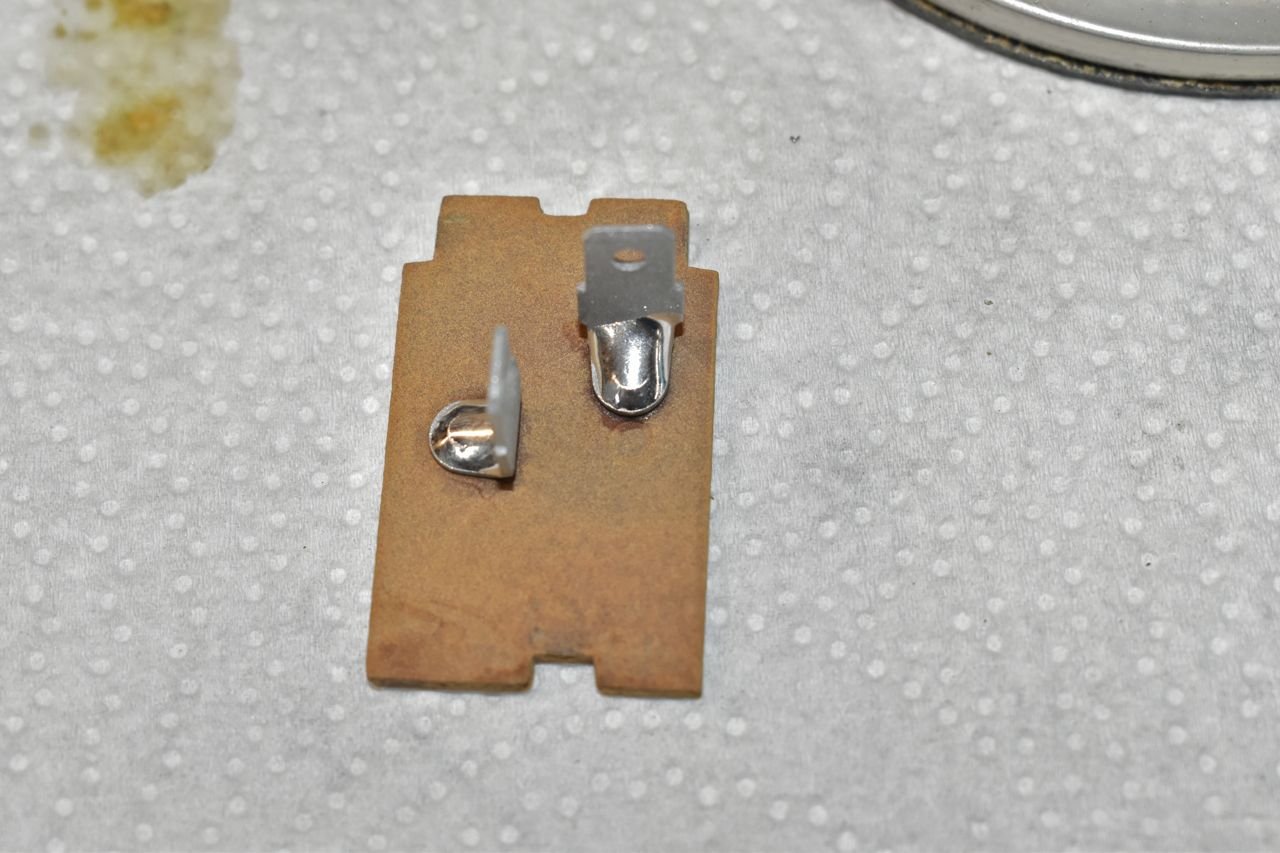

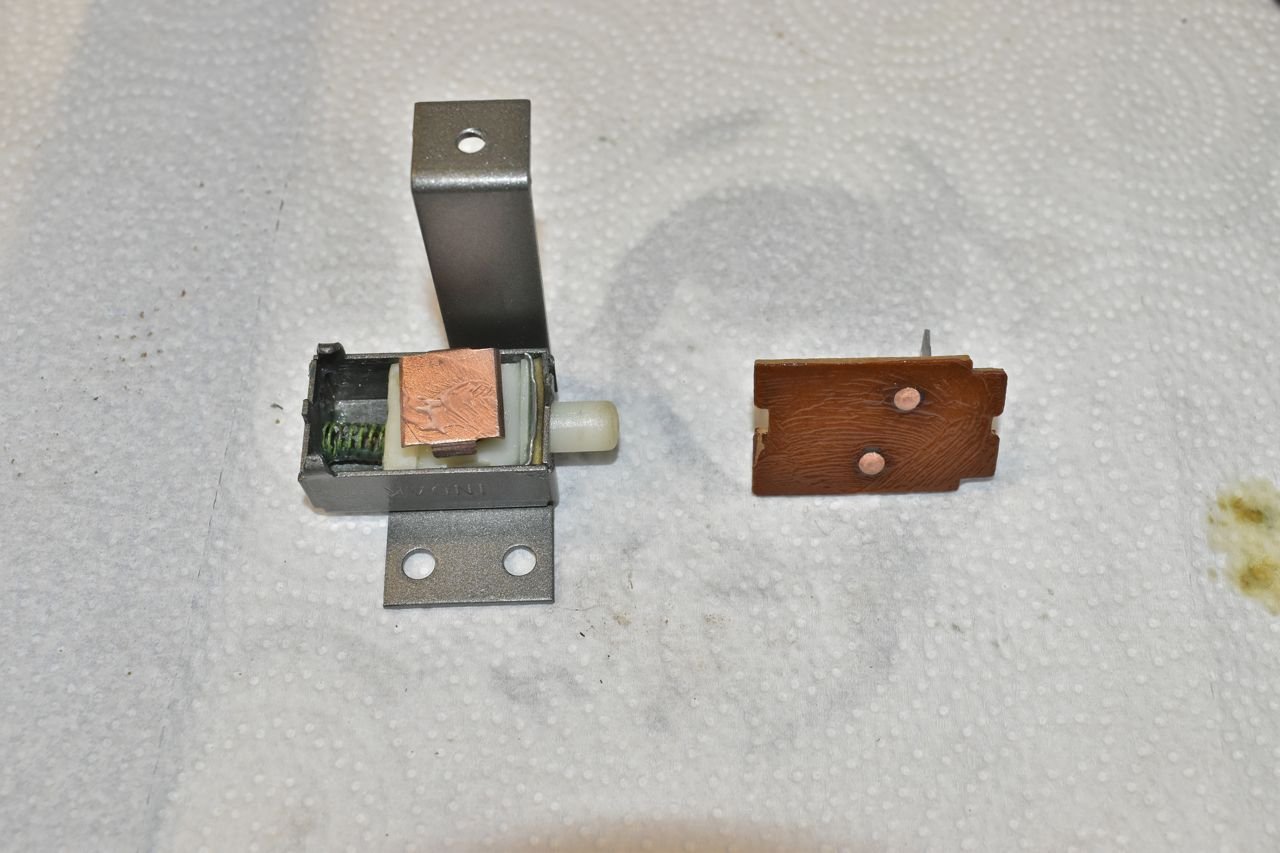

All the parts cleaned and the shell painted. The one area of concern is the contacts. The swage tends to come loose and the best way to fix it is just solder the terminals to the copper swage pins. Even at a clutch current of 3-4 amps with a loose contact can cause the switch to burn and or the plug/wires.

Now there are no worries.

I use a waterproof teflon based grease for the lower sliding section and clear silicon for the contact section.

You won't have to worry about this switch for the rest of your natural now.

Always test your work for no surprises later sort of thing. The switch should be open when the plunger is out.

And closed when depressed.

Now for the plenum case itself.

This is after walnut blasting it. It's so weak and shed so much loose plastic like a snake shedding its skin. It feels like it would crack in half easily enough now. This is the not so fun tedious, monotonous, pain the butt (have I made my point yet ) process of layering on fiberglass resign with sanding in between coats to build this back up. This is very time consuming and messy. Especially messy.

You get the idea. The old plastic is basically entombed in resin all the while keeping its shape and critical dimensions.

It's not perfect, but it'll do as my patience just ran out with this. I didn't know if I should paint it or clear coat it. If I painted it would be one contiguous colour but you'll know it's painted. If I clear coat it, you'll see the yellow in areas of heavy resin or all resin where the plastic broke away. I decided on clear coating it as you can still see the glass reinforcement in the original plastic on most of it. Looks more original that way.

I laid the resin heavy in the interior. This really helped with structural integrity. It's really stiff now and doesn't feel like it would just crack in half.

continued in next post.

Click here to continue to part 80