1966 Ford Galaxie 500 XL Refurbishment : 058 York Refrigeration Compressor Rebuild, part 1

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74 - 75 - 76 - 77 - 78 - 79 - 80 - 81 - 82 - 83 - 84 - 85 - 86 - 87 - 88 - 89 - 90 - 91 - 92 - 93 - 94 - 95 - 96 - 97 - 98The new radiator arrived. However..........

Thank you Fed Ex for destroying a 752 dollar radiator. I swear FRAGILE translates to double dog dare you to destroy this package.

So the company is making me a new one, but it could be 16 weeks before I get it. (shaking head)

I don't know what some people think at times or if they even think at all. That expensive radiator should have been mini-crated in that box with 1/4" ply protecting it. Perhaps the new company that bought US Raditors will reconsider their shipping containers as even if they file a claim against Fed -Ex they still are going to have to eat a portion of that cost if not all of it, especially if Fed-Ex denies the claim, which they probably will.

752 dollars is not pocket change. Plus now I have to wait even longer to get another one.

Not happy.

Refrigeration Compressor

The old Yorks aren't worth trying to rebuild as they make them brand new still and for less than 200 dollars.

Too bad it's made in china.

For those not familiar with the history of the York style of compressor, it debuted in 1958. Even the brand new ones to this day are darn near identical. The only differences are they added ports in the low and high side for pressure switches in the back and I do believe the high side has a blow off valve in the port.

Even though the bolts have the metric hardness markings the threads are still SAE/English. Rather amusing.

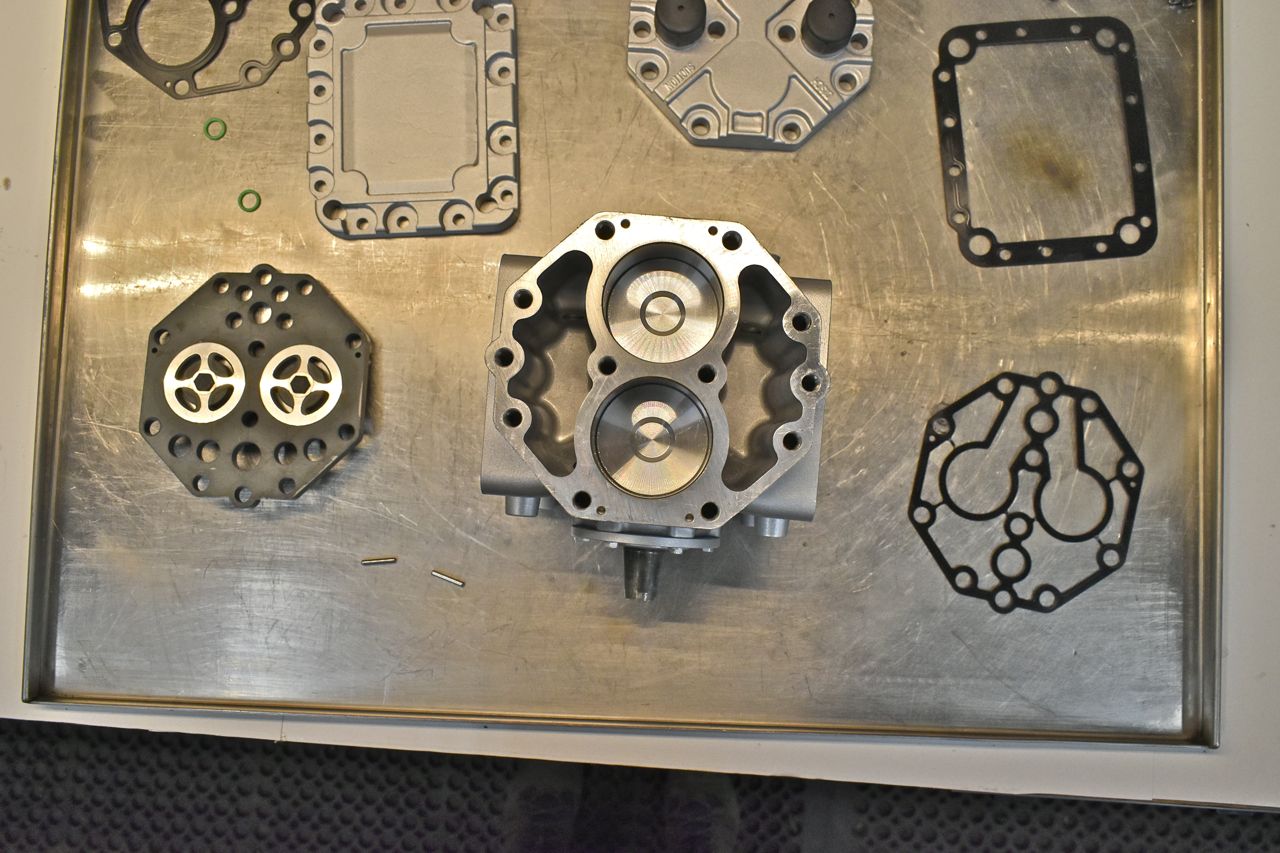

The York 210 decodes to 2 cylinders and 10 cubic inches of displacement. There's smaller displacement older versions as well as the Tecumseh which looks very similar and is interchangeable only it's made out of cast iron. The smaller displacement compressors are used with dealer installed under dash units as the BTU capacity is much lower on those.

Using a 210 on a dealer installed A/C without a larger condenser or high fan flow through the condenser will result in higher line pressures which wastes fuel and puts the compressor under more strain. This is a situation where bigger is not better.

Another fact worth noting, this is a very simplistic compressor, there are less moving parts in this compressor compared to a modern Sanden or the like. This has less friction than a newer compressor and uses less energy. It also sports a much better front seal. One more thing, the reason why these seemingly old crocks are reproduced is because they were used on new class 8 trucks and still might be. New class 8 trucks (semis/lorries) have a requirement from the parts they use. The parts they source for their trucks must meet 10 years / 1 million miles.

Now that is the kind of part I'd want on my car

Why anyone would buy the Sanden retrofit kit is a bit beyond me. The one downside of the York 210 is that it is only 2 cylinders and you are more likely to feel the pulses of compression on the vehicle. However if it's a problem, you can mitigate the vibration by using a muffler on the discharge line.

Inspected, oil drained, detailed and inspected.

These are the braces for the compressor.

Now this is the tricky bit, this brace originally attached to the OEM exhaust manifold. I'll need to make a bracket that mounts to the exhaust bolts to secure this too. I'll get back to this.

Let's go over clutches.

The most common clutch for the '65/'66 is the Eaton clutch. However the drawback is that it requires an external brush because the electromagnetic coil is part of the pulley and spins with it.

Typical example.

The clutches on these York's/Tecumseh's is measure in two key areas, the diameter and the sheave offset from the centre of the bolts atop the compressor to the centre of the sheave. There are many different clutches in different diameters and different offsets. Never assume they are all the same.

This is the clutch from my '68 XL with FE. The diameter is the same but the sheave offset is about 6 mm inboard than on the '65/'66 setup. This would not make for a happy belt alignment.

Now the problem with the Eaton clutches for '65/'66 is they do use that external brush and that requires maintenance otherwise excessive arcing will occur and aside from never getting an AM station without tons of noise you can even have clutch chattering if the slip ring and brush get really dirty.

Now the '66 gal 500 XL came with a Pitts clutch in which it uses a separate stationary coil and no brushes.

Here's the Pitts on the left and the Eaton on the right. Both are the same diameter and with the same sheave offset.

You cannot go by overall height as shown here as when installed the pulley sheave offsets are equal. The Pitts clutch is the better clutch, but seemingly more rare. I hunted down an NOS coil for it and I think I have a line on a core clutch. But that was searching pretty much the entire internet (what a time vampire that was). I would like to get another clutch and coil to retrofit the LTD's compressor clutch which is an Eaton.

I cleaned the Pitts coil and found the epoxy cracking and worried that water or oil might ingress compromise the copper windings I sealed the face the epoxy with Ultra Black RTV. I have to take care of this coil as they are seemingly rare as hens teeth.

The insulation on the wire is geting VERY hard and I would not trust 50+ year old wiring.

Continued in next post.

Click here to continue to part 59