1966 Ford Galaxie 500 XL Refurbishment : 056 Power Steering Pump Rebuild, part 1

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74 - 75 - 76 - 77 - 78 - 79 - 80 - 81 - 82 - 83 - 84 - 85 - 86 - 87 - 88 - 89 - 90 - 91 - 92 - 93 - 94 - 95 - 96 - 97 - 98Power Steering Pump

This is a long one. It shouldn't have been, but it was. I swear this thing was cursed. Let me start from here. First of all the PS pump that was in the '66 gal 500 XL was the wrong pump. Take a peek once more:

It may be hard to tell but this has the skinny fill neck and slide in dip stick. For '65/'66 it should be the angled back (air conditioning) and the fat neck with the twist off cap with integrated dip stick. The reason why will become clearer later on. With that I used the pump from one of the donor cars. Well, some of it.

I rebuilt this pump about 7 years ago as part of this adventure The Unlikely 400 Dollar FE Refresh.

But since I only did the pump and not the steering gear I wanted to clean this out and change the seals.

And this is where the fun started. Did I say fun... perhaps not the best word.

So the bushing is breaking apart and disintegrating. Now this is the second bushing because I changed it because the original completely fell apart when I did this pump all those years ago. I can only surmise the remaining oil in the steering gear perhaps became acidic sitting abandoned for decades in the Indian Reservation. This poor car only had about 30K miles on it and it was left for dead.

Now this is a rare kit number as it contains a new bushing. The more popular 8501 just contains the seals. However I noticed BBB Industries is reproducing this pump. This begs the question just how good are the reproductions. If it's anything like the other reproduction parts for these cars I'll pass thank you and try to rebuild the original parts.

Now this is interesting, this is the Clevite part number. A while back I contacted Clevite to see if the part was still available. It was not.

Another interesting tidbit is after I finished this pump I happened to stumble across another kit that is still available that claims to have the bushing, seals and slipper springs. So I ordered two, it'll be interesting to see if that bushing is really included and where it's coming from.

The entire kit.

I started with the pump reservoir. It's cleaned and stripped. Now I am making modifications and some might find this interesting why I am doing this. Two or so months ago I posted a question on the HotRodders forum to see if people are using an old car (40+ years) as a daily driver and if so what did they do to it to make it reliable.

There was a plethora of responses. One stood out as stating he would never use AN lines/fittings as auto part stores do not stock them and if the car breaks down where locally could you get hoses. OK, that is a valid point.

But if I may agree to disagree and I'll explain. Back when I was doing the '66 LTD, the correct power steering hoses were no longer available, as in anywhere. There were hoses offered but they were really long (some other application) and you can not modify the high pressure hose so you were stuck and that was through Rock Auto and the local stores didn't show anything.

That's why I converted the LTD's power steering system to AN fittings. In the last year or so I noticed the correct hoses are offered again. I would suspect the boom in the economy from the last administration prompted companies to service once more the niche market cars (these 3rd gens fall into that category) as it made business sense to do so even if the profit margins aren't stellar.

However I wouldn't count on that in this administration. I would suspect some parts to go off the radar again as business have to evaluate their business plan (tighten production) once more in this new waning economy. With that thought I'm also doing this gal 500 XL in AN lines. But here's the thing to consider, even though I am making the lines myself and ordered through a speed house (Summit) in a pinch if the line blew away from home I can hunt out just about any airport; international, regional, or even those little house subdivision airparks where there is always an aircraft mechanic stationed or around.

If I need a temporary high pressure hose, it's very easy to call these A/P shops and have a certain length AN hose made the same day. Aeroquip 303 hose (common aircraft line) in 6 AN can handle about 1000 PSI and in 3 AN (brake hose) about 3000 PSI.

With that I beg to differ in that if away from home you can get AN lines made same day if you hunt down an airport. Just have to think outside the box.

Weld on AN fitting.

I use stainless ER312 welding rod as it's pretty forgiving on unknown steels (any traces of galvanizing still left, etc).

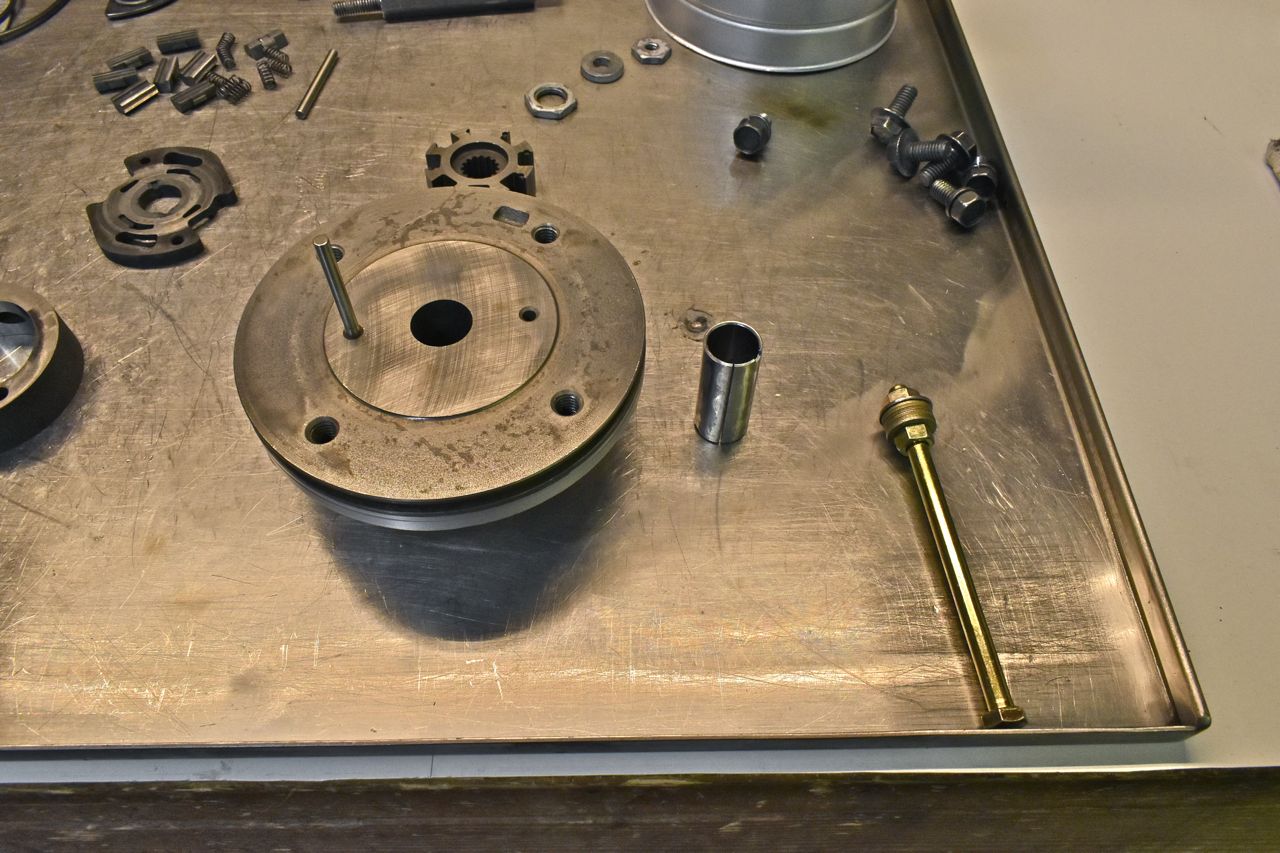

Onto the rest of it. Now on the pump there is always one pin that is pressed in and the other floats. The pressed in one on the pump from the donor car was slightly bent and I went to lightly straighten and it broke right off.

OK, so even though the pump in the gal 500 XL was the wrong year pump, most of the insides are the same. That pump donated a new front.

Here's my little press in tool for the bushing.

Works a treat without harming the bushing.

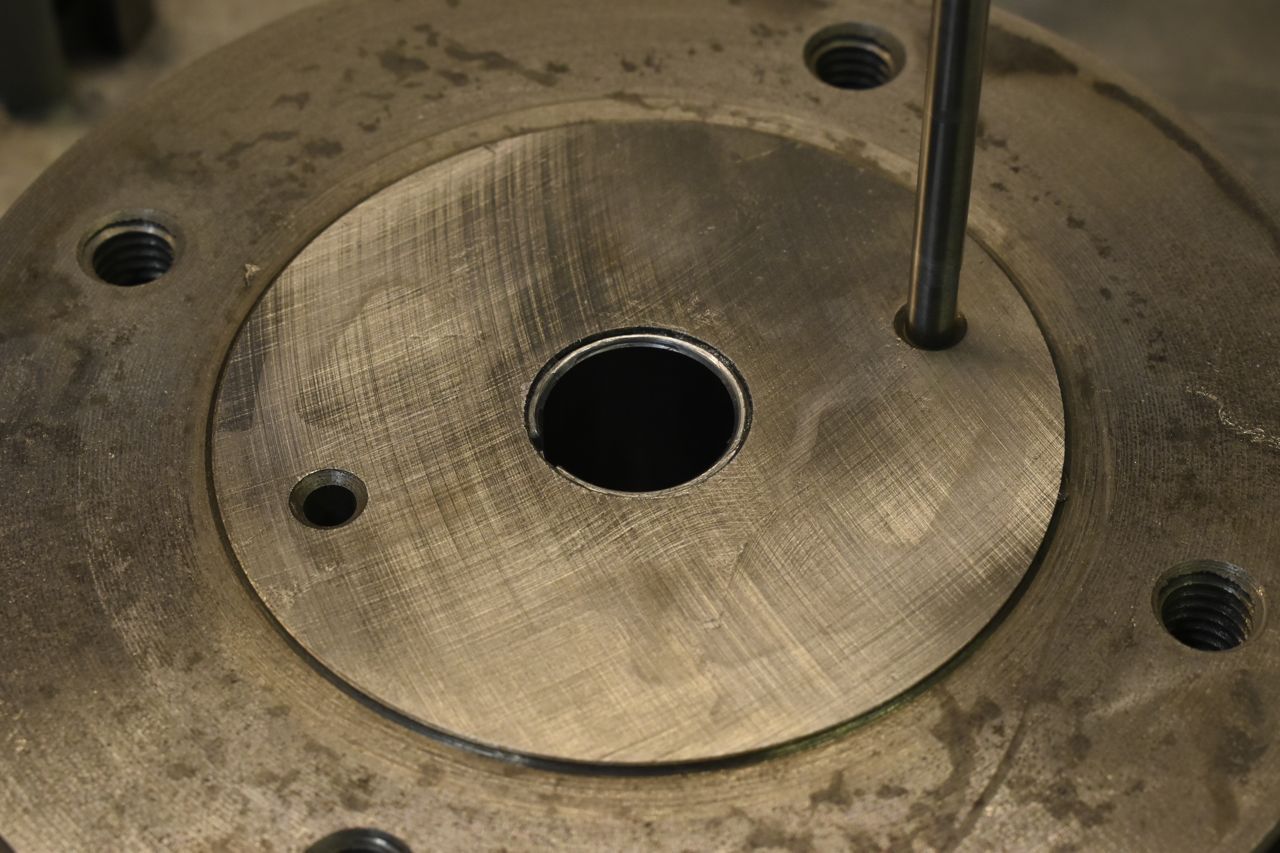

The new front seal doesn't have sealant around the perimeter like other press in seals do. So a little Ultra Black RTV was lightly applied to the seal perimeter first.

Installed and excess wiped off.

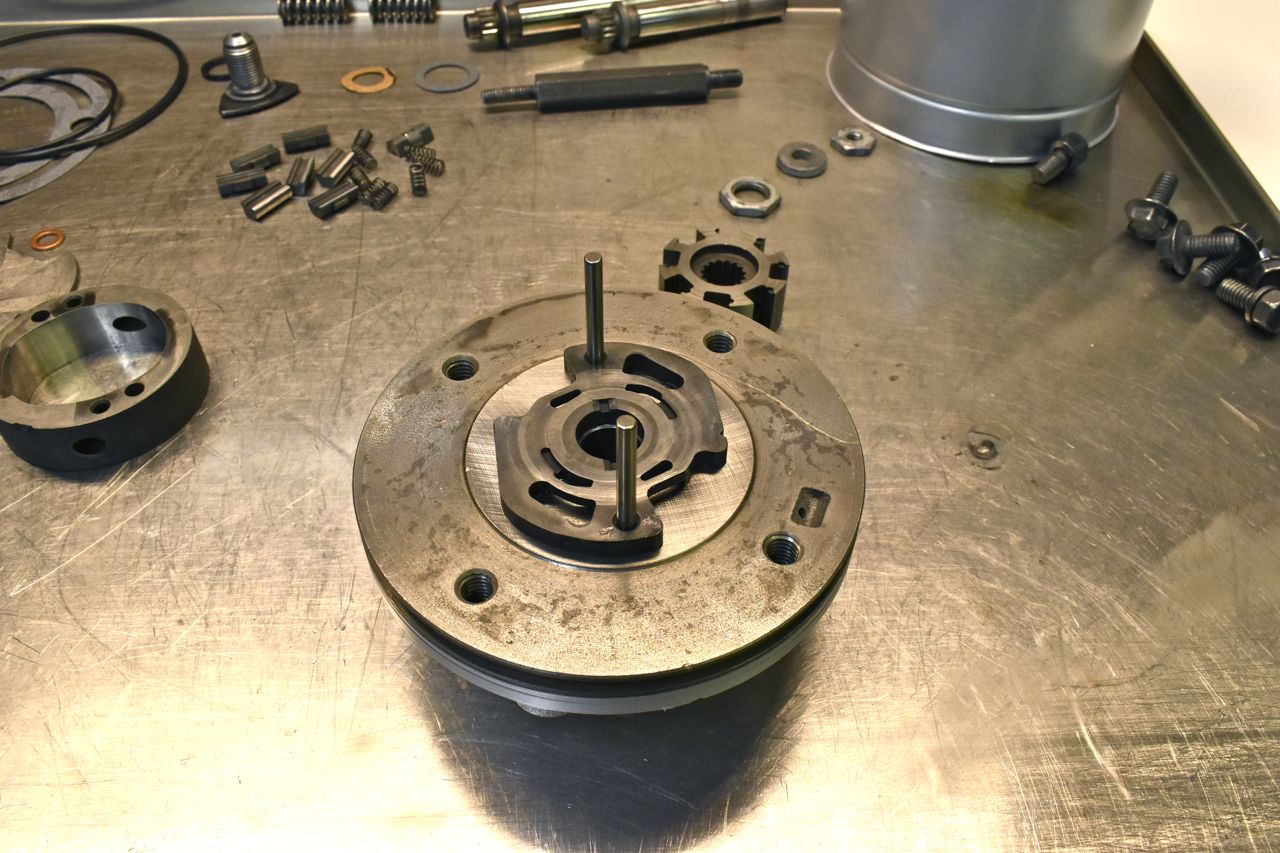

The front pump end plate. The one on the left is the donor car and it's gouged. There had to have been crap in that steering gear and even though I cleaned the pump all those years ago, some of it flushed back into the pump.

Lesson learned, never rebuild just a pump, do the whole system at the same time for something this old!

When assembling these or even transmissions, you can use Vaseline for the assembly grease. It dissolves in ATF. Actually I think the '66 or '68 Ford Service Manual says to use it.

One of these shafts is pretty worn.

The teeth on the right side shaft are worn more. The shaft on the left is also darker suggesting it had a better heat treat process.

On the pump stator and the slippers take some Scotch Brite and cross hatch each item. Noisy pumps are usually caused by a combination of weak springs and polished hardened parts trying to ring together. Installing the cross hatch allows oil to creep between the parts and prevent the ringing together.