1966 Ford Galaxie 500 XL Refurbishment : 096 Power Window Regulators, pt 4 : Regulator swap

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74 - 75 - 76 - 77 - 78 - 79 - 80 - 81 - 82 - 83 - 84 - 85 - 86 - 87 - 88 - 89 - 90 - 91 - 92 - 93 - 94 - 95 - 96 - 97 - 98

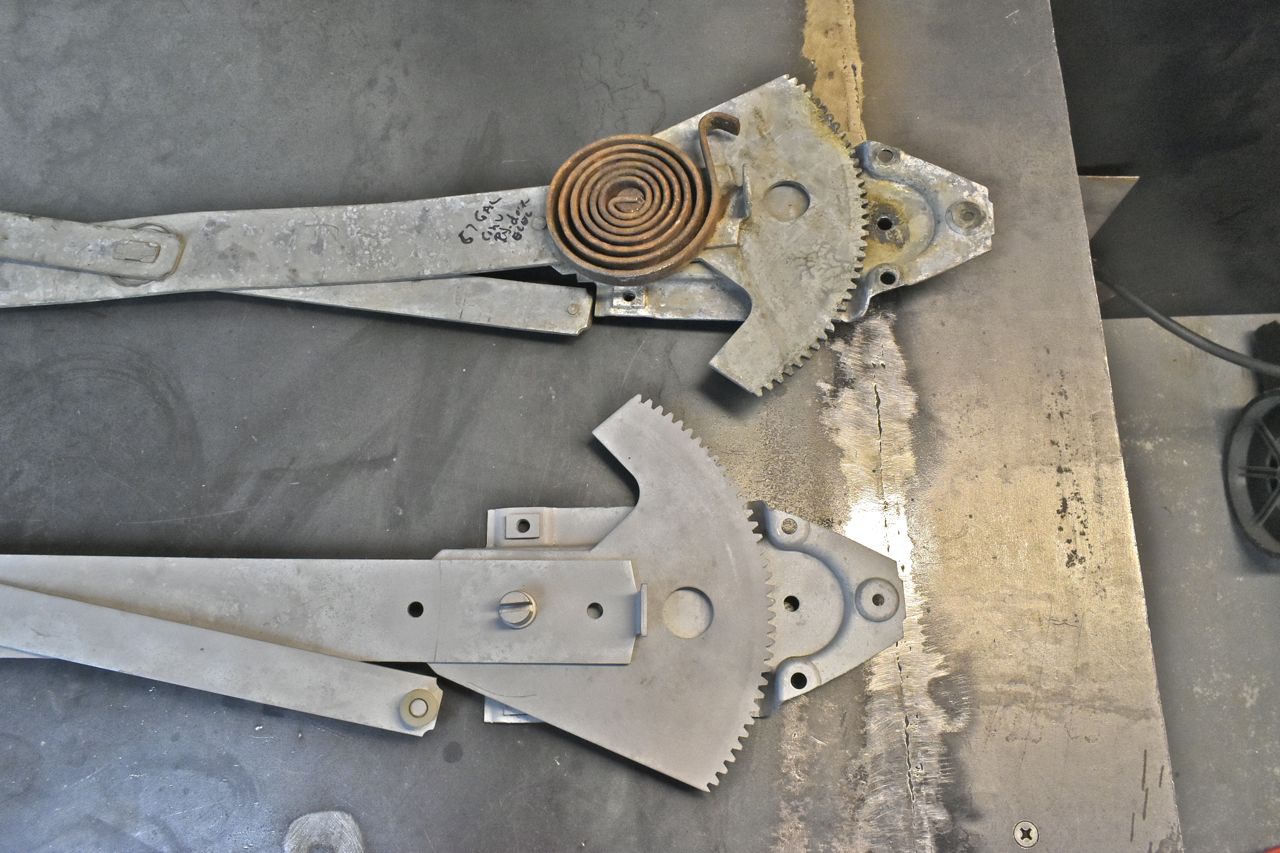

Another problem that presented itself was I only had the same side front door regulators for the 1966 gal 500 XL. It was the only two I could find at the time. I needed to turn one right into a left. It turns out it's easier than I thought as it's all the same parts for left or right front door regulators irrespective of which side they fit. What you have to do is simply flip the sector gear around to the main arm.

First step is to disassemble the regulator as previously shown by grinding off all the swages.

Remove the base plate.

Next grind off the rivets holding the sector gear onto the arm.

Then separate the sector gear from the main arm as shown.

This is the idea; flipping the sector gear around. Now there is a left and right.

There's not enough room for conventional hardware, so heavy duty solid steel rivets need to be used to reattach the sector gear. I just used a 20 ton press to set these. Then I proceeded to R&R both regulators like the first one.

Four down and 8 to go.

The rest of the regulators to go through. Quite honestly it just looks like a pile of scrap, however to the trained eye it's a veritable gold mine of antique parts.

The old 1960's motor have an overmould of rubber on them (vulcanized). This is actually a bad thing as it can trap water underneath and cause the motor to rust away faster. As I previously mentioned Hancock made the regulators and motors for Ford. In looking at the rubber overmould, it simply wasn't dipped but rather it was an actual steel injection mould with a type set capability to denote the part number and date of manufacture. I have surmised why Hancock did this, on an economic model it's cheaper than painting and having to seal the end caps to the motor shell. So they forwent the painting for rust protection and just went with a rubber overmould with the part number and time stamp as part of that process.

You can see the rust pitting starting in the steel shell case. This is a perfect example of why you should never undercoat your car. Some of that rubber just fell off and some of it was a real bear to remove. And that's why I will never use any rubber or harder material to coat a vehicle. One small pocket of trapped water and it spreads like metastasized cancer at that point. Now when I assemble the end caps to the motor shell in these old Ford motors I apply a small a small ring of Ultra Black RTV (low corrosive action to aluminum) to them. If you look at the following picture closely you can see the black RTV wedged in there. Once the end caps are tightened to the motor shell I smear RTV around the outside to really seal the interface then wipe off the excess.

This is a more severe case. This is one of the spare Ford motors from 1966. It's starting to look like the surface of the moon in some areas. Thankfully they used 11 gauge thick steel as I thought for sure this would be breeched the steel with a pinhole or two, but alas no there's still metal even in the deepest pits.

The spare motors. They look aesthetically horrible but are otherwise fully restored. One had water ingress into the motor shell and it loosened the glue holding the magnet into the shell. The magnet was in a different location than where it should have been. I used JB Weld to secure the magnet to the proper place after the whole shell spent some time in the electrolyses bath then sandblasted so all corrosion was removed first. The interior was painted as well as the exterior.

Weirdly all the old regulators that came with old motors still worked to some degree when they arrived. The only regulators that had motors were the 2 rear quarter window regulators for the 1966 2 door coupe (pictured above) and all the regulators for the 1968 2 door coupe.

Click here to continue to part 97