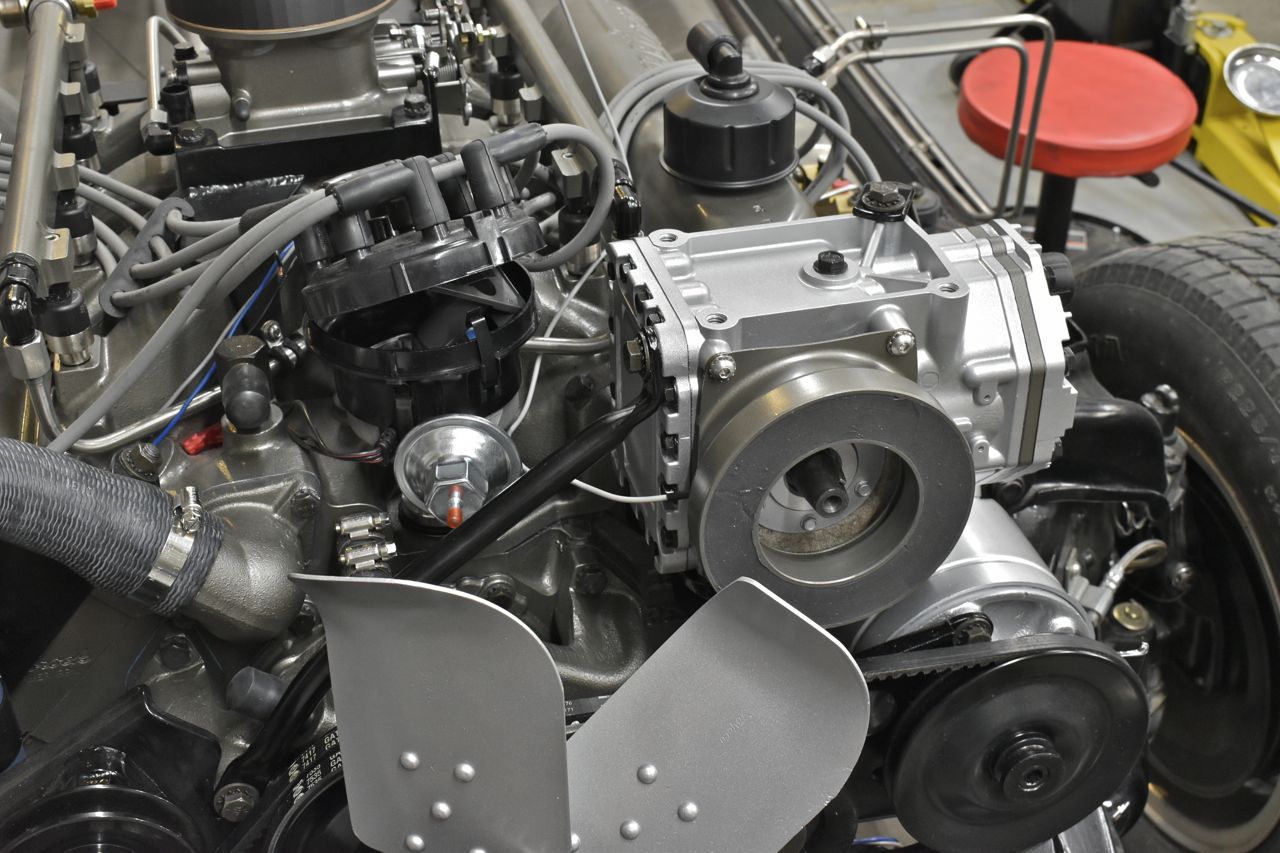

1966 Ford Galaxie 500 XL Refurbishment : 059 York Refrigeration Compressor Rebuild, part 2

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74 - 75 - 76 - 77 - 78 - 79 - 80 - 81 - 82 - 83 - 84 - 85 - 86 - 87 - 88 - 89 - 90 - 91 - 92 - 93 - 94 - 95 - 96 - 97 - 98Refrigeration Compressor Continued

I am going to splice in some new GXL wire close as I can to the coil assembly. I used a western union splice, soldered, then inner melt polyolefin heat shrink (has sealing glue to keep out contaminates) then over that PVC heat shrink as a hard outer cover resistant to chaffing.

I cleaned and painted the Pitts clutch. I have a new bearing for it. This clutch uses a metal shield (lower right side piece) that goes in before the bearing. Then the spiral snap ring is installed.

I used the press to install these pieces.

On the clutch shoe there is a spacer that is used.

Then press in the shoe.

Then the snap ring is installed.

Tightening the bolt can be a bit tricky as there is no provision in the clutch shoe for a tool to hold it. So you can energize the coil to engage the clutch. This ties the shoe to outer pulley where it's easier to hold.

The correct belt for this application.

That A/C idler pulley deflects the belt just enough to keep it from slapping when the air con is running.

Here's a bracket I made for the hanging York brace. It's 3/4 hard 4130 steel. It doesn't need to be really thick.

I made a little bracket for an Adel clamp for wire management.

I will say this, the '65/'66 FE with air con has some of the oddest belt geometries.

More to come.

Cheers

Click here to continue to part 60