1966 Ford Galaxie 500 XL Refurbishment : 053 Engine - Custom Oil Pan Design & Fabrication

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74 - 75 - 76 - 77 - 78 - 79 - 80 - 81 - 82 - 83 - 84 - 85 - 86 - 87 - 88 - 89 - 90 - 91 - 92 - 93 - 94 - 95 - 96 - 97 - 98Oil Pan and Things....

Thought I'd share a little more progress.

Here's the factory oil pan, it's fine for a slow car, but a brisk acceleration and the oil pump risks sucking air as all the oil goes backwards and away from the pickup. So the plan is to increase the capacity of the pan and make a pocket of reserve oil for the pickup under a bit of power.

I also want to add a low oil sender and oil temperature sender in the pan. I will use these. I like the Ford low oil level sender as it's metal unlike the GM ones.

I've already removed the pitiful inner baffle.

I want to do something like I did here, just with a few minor changes. This is the LTD's 390 I did a while back. I took measurements off this one to mark up the other pan. You can read about that oil pan here : 1966 Ford LTD Custom Oil Pan

I am using 16 gauge steel to make the larger portion of the pan.

One side boxed in.

Making the drain plug ramp.

Making the templates for the baffle.

Other side cut out.

Rest of the oil pan boxed and sealed.

This is how the baffle will look once it's welded in. But before that I want to check my welds for leaks.

I found this works really well for leak checking. It's viscosity is near water, doesn't oxidize steel and has green colourant that leaves a green stain around a leak.

Must be my lucky week, over 8 linear feet of weld and not one leak. I let it sit an hour.

I welded the baffle in and did one last leak check. I should buy a lotto ticket, still no leaks.

Ready for paint. So my idea with this pan was to create a sealed pouch of oil around the pickup. All the similar pans without dedicated traps and special pickups had holes around the baffle. This baffled me (pun intended) because under a hard acceleration the oil wouldn't stay in the pouch and just drain back. So all the ones I looked at Summit didn't make much sense to me. Maybe I'm missing something. Dunno.

Getting painted.

Final product compared to an original FE pan for these low frill base FE's.

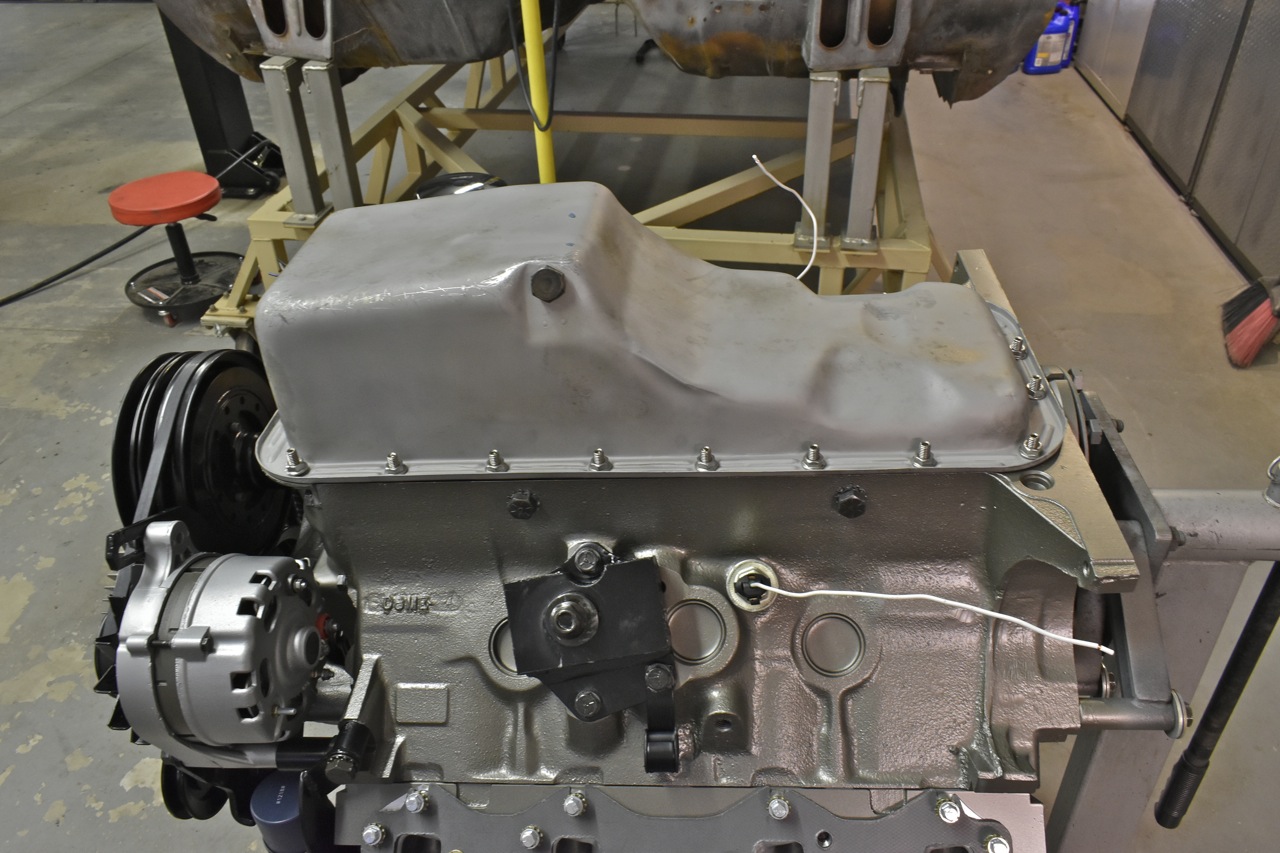

One last thorough cleaning and installed.

It's ready for installation. I was going to run this on a dedicated stand, then I thought, just put it in the chassis and run it there. Duh....