1966 Ford Galaxie 500 XL Refurbishment : 097 Power Window Regulators, pt 5 : Springs

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74 - 75 - 76 - 77 - 78 - 79 - 80 - 81 - 82 - 83 - 84 - 85 - 86 - 87 - 88 - 89 - 90 - 91 - 92 - 93 - 94 - 95 - 96 - 97 - 98Naturally I attacked the easiest regulators first. The remainder with the hinge arm to the main sector gear were a little more involved. Lets have a look.

This is the rear quarter regulator for the 1968 only 2 coupe and convertible. The grease was so baked it completely hardened in this one. The regulator was so stiff it barely moved.

The idea with these is to proceed like the other regulators but the shouldered rivets/fulcrums used for the sector gear and the pivot side extension arm need to be removed by grinding off the swaged area as well. Again it's a matter of drilling a through hole through these and tap for 1/4"-28. It's a little more work, but in the end it's worth it.

Here's that one refurbished compared to the other side. What a difference, not only does it look better but they move very quickly and smoothly when tested with a 12.6V battery.

The rest were completed in this fashion.

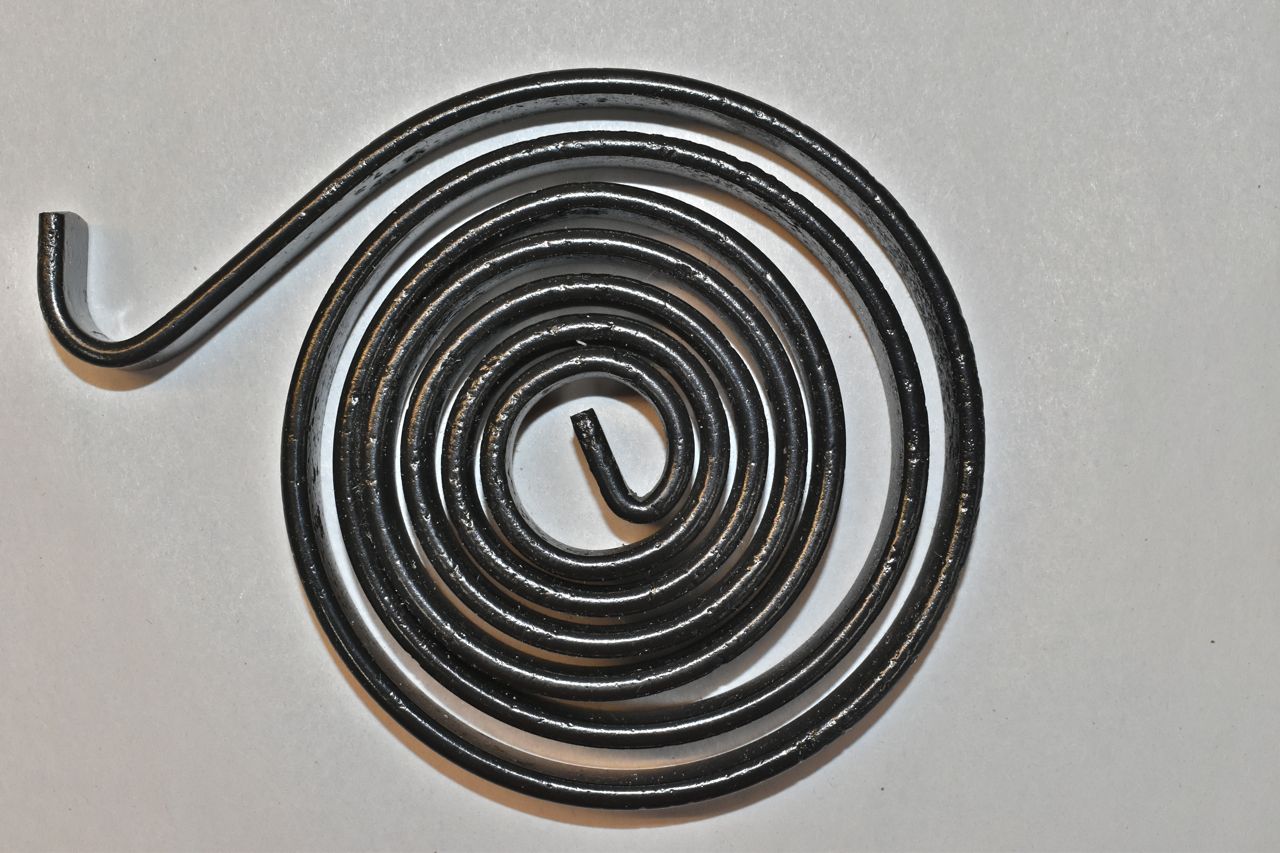

I would like to spend a moment on the window counterweight spring. It's a seemingly trivial part but there is a problem with them. The main problem is corrosion. It appears Ford never painted these, at best they were coated with an oil or grease and after 50+ years it's long gone leaving the spring metal to pit badly in certain conditions.

In extreme conditions it already lost its tension and is basically falling apart before your eyes.

Or under light pitting conditions it may fool you. This spring is cracked and would probably let go with violence if you tried winding it back up on the regulator fully. Ironically this was intact on a regulator but did not fracture (stress fracture from pitting) until I removed it. I didn't realize it at the time. It went in an electrolysis bath to remove all the corrosion, sand blasted, then painted. When I went to start winding it back up, it made an unholy noise and at that moment I felt like I was staring down the barrel of a loaded gun. I carefully unwound it and you can see where it cracked by the distortion.

What's the lesson? Do not reuse noticeably pitted springs. The manual window regulator spring is the same as the power regulator, so try and find a better example to use if yours looks like this above. I had to pillage two extra spare doors for the springs because some of them were just so bad and like the one pictured above.

Here's something else to consider. That spring is right beside the door glass or quarter glass when the window is down. If it lets go (violently) in that state it very well could shatter the glass. So just ask yourself, which do you prefer to replace? The entire glass and spring later or just the spring now……….

When you're refinishing these regulators and it doesn't matter if it's a manual or power, you want to thoroughly remove ALL corrosion (electrolysis bath & sand blasting), paint it, then grease it so the coils can easily slide over themselves as the regulator is used.

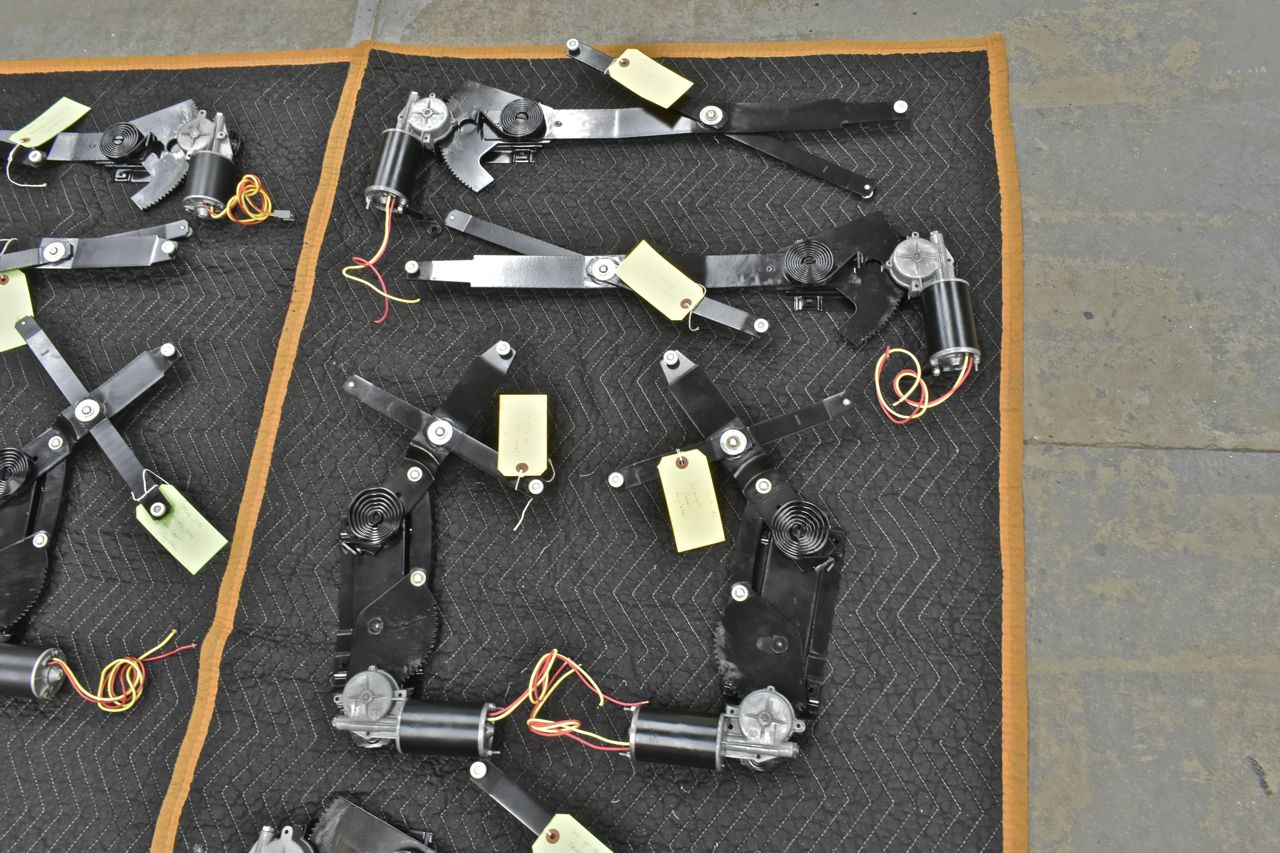

Here's the final results. I'm starting to feel like a remanufacturing house. This is not to be taken lightly. The average time spent in man hours per Ford regulator is approximately 8 full hours. This took loads of labour, even the epoxy paint I used is getting expensive. Some general numbers are 350 dollars just in paint, add in the cost of buying the original regulators and about 500 dollars in aftermarket ACI motors that needed rework right out of the box and some couldn't even be used, not less forgetting about hardware and the nylon 6-nylon 6/6 used to recreate the rollers and you can see the expense in this. With a shop time of even a low 75 per hour (most shops are well above 100 per hour and large restoration shops are around 150 per hour), it's around 3000 dollars per set when its all said and done and that's throwing the engineering and testing time for the rollers in for free.

A little explanation about the regulators shown above is in order. All the tagged regulators are for the 3 Ford cars (XL, LTD and gal 500 XL), the Ford style Franken-regulator is at the bottom right and since it works I'll just keep it as a spare. Just as a comparison I decided to show what power window regulators look like for a 1971-1976 General Motors B body 2 door coupe and convertible look like. 71-76 GM B body cars include Bel Air, Impala, Caprice/Caprice Classic, Centurion, LeSabre, Delta 88, Grandville, Bonneville, etc. If you thought power window regulators were expensive for old full size Fords, try finding original power window regulators for the aforementioned GM B body cars.

I'd like to go over the fitment to the models of cars for the Ford power window regulators. This will be important to those looking for original style regulators for their cars. Oddly enough every Ford power window regulator is here for every conceivable 1965-1968 full size models.

These four regulators with green tags will fit any and all 1965-1967 full size 2 door coupe/sedan or convertible. In fact the front door regulators (two up top) will fit 1965-1968 full size 2 door coupe/sedan and convertibles. The only difference will be the rear quarter window regulators; 1965-1967 are one type and 1968 is its own type.

These 4 regulators with yellow tags will fit the 1968 full size 2 door coupe/sedan and convertible. Just to reiterate the front door regulators are the same for 65-68 it's just the rear quarter window regulators that are different. 1968 rear quarter window regulators have the equalizer arms and more remotely located motor.

These 4 regulators with the green tags will fit 1965-1968 full size 4 door hardtops and sedans.

This is a better comparison between the 1965-1967 and 1968 2 door coupe/sedan/convertible rear quarter window regulators. There's quite a difference!

A word about NuRelics and what I've researched about their version of reproduced power windows for these Fords. I would not use them for a number of reasons and I shall list them for others to consider.

First, NuRelics claims that the rear quarter window regulators are the same for 1965-1968 and as we can see that's simply not true. They show the actual 1965-1967 regulators for 65-68.

Secondly they say they use brand new ACI motors in all their regulators. Well I have shown why that's a major cause of concern right from the get go. NuRelics also seems to use only one style of motor at that and that's the GM newer style. There's no hope of retrofitting an old Ford motor onto them, plus the motors are in different locations than the originals. As an addition, the newer GM style window motor is riveted together and just meant to be a throw-a-way, whereas the older Ford style motors are in fact serviceable. Why pollute the landfill with cheap disposable parts, refurbish older well made parts and save the landfill. This is a much better environmental solution.

Thirdly, whilst I couldn't find any video examples of their late 1960's Ford regulators in operation in a vehicle I did find video examples of their GM A body regulators in use (think Chevrolet Chevelle). My concern was how much torque do those ACI motors generate and how accurately did NuRelics make the window counterweight spring to match the weight of the actual window glass and frame. Well it turns out not very well. I watched videos where the glass in the door went down quickly but really struggled to come up.

Then of course there are other concerns that can't be validated such as what kind of material are they making the rollers out of. That sort of thing, which again I have shown is extremely important for long life.

I had made the decision that even if I couldn't find all the original regulators I would make them, hence the first one; Franken-regulator. I'd rather have that and have it raise and lower the glass quickly with long term reliability than an aftermarket one that was not only expensive, but irritatingly slow.

These 4 power windows are also interesting. They look darn near similar and for the most part they are. The 2 on the left are for the rear doors of a 1965-1968 4 door hardtop or sedan whilst the 2 on the right are only for the 1968 2 door rear quarter windows. In refurbishing these I did learn that they are identical with the exception of the length of the swing/equalizer arm. That's it. That means if you couldn't find 1968 2 door rear quarter regulators you can use 1965-1968 4 door regulators (the rear doors) and just shorten the swing/equalizer arms to match the manual regulators in the 1968 2 door. Or vise versa. Although you're more likely to find 1965-1968 4 door regulators than you are 1968 2 door quarter window regulators. It took me several years to finally find 1968 2 door coupe power regulators.

The regulators above are the front door regulators in comparison between the 65-68 4 door models and 65-68 2 door models. I learned the base plates are the same along with the sector gear. What's different is the window counterweight spring, the main arm length and the length of the swing/equalizer arms.

That concludes the power window regulator portion. Now I would like to talk about power window switches. I have not been able to find proper reproductions for the door mounted switches of the 65-68 Ford full size. I did find a reproduction quad switch for the 65/66 gal 500 XL console, however since the console I have for the '66 gal 500XL never had power windows, there's no provision to really mount them.

Click here to continue to part 98