1966 Ford Galaxie 500 XL Refurbishment : 093 Power Window Regulators, pt 1 : Rollers

2023, November 14

1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 - 11 - 12 - 13 - 14 - 15 - 16 - 17 - 18 - 19 - 20 - 21 - 22 - 23 - 24 - 25 - 26 - 27 - 28 - 29 - 30 - 31 - 32 - 33 - 34 - 35 - 36 - 37 - 38 - 39 - 40 - 41 - 42 - 43 - 44 - 45 - 46 - 47 - 48 - 49 - 50 - 51 - 52 - 53 - 54 - 55 - 56 - 57 - 58 - 59 - 60 - 61 - 62 - 63 - 64 - 65 - 66 - 67 - 68 - 69 - 70 - 71 - 72 - 73 - 74 - 75 - 76 - 77 - 78 - 79 - 80 - 81 - 82 - 83 - 84 - 85 - 86 - 87 - 88 - 89 - 90 - 91 - 92 - 93 - 94 - 95 - 96 - 97 - 981965-1968 Ford Full Size Power Windows

This is a long saga with quite a few revelations along the way. It all starts with the testing of my Franken-regulator, which is a 65-68 front door regulator for a 2 door coupe/convertible I made from an original 1966 manual regulator and a reproduction 80's Ford pick up power regulator. Whilst the regulator worked just fine, I did use reproduction Dennis Carpenter rollers and a new reproduction ACI motor. Both the brand new rollers and motor ended with problems. Let me explain.

Just to recap this is the Franken-regulator I made. I had originally made this front door regulator because I couldn't find the OEM front door regulators that fit 65-68 fills size models; 2 door coupe and convertible. So I set forth to see how much trouble it would be to create one. For the full article on making one see here : Ford 1968 XL Restoration : Custom building a Power Window Regulator

From the left side is a manual window regulator for 65-68 full size Ford 2 coupe/convertible I used. To the right of that is a 80's Ford pickup power window regulator I used to amalgamate the two together to produce the pieces painted in black ready to assemble.

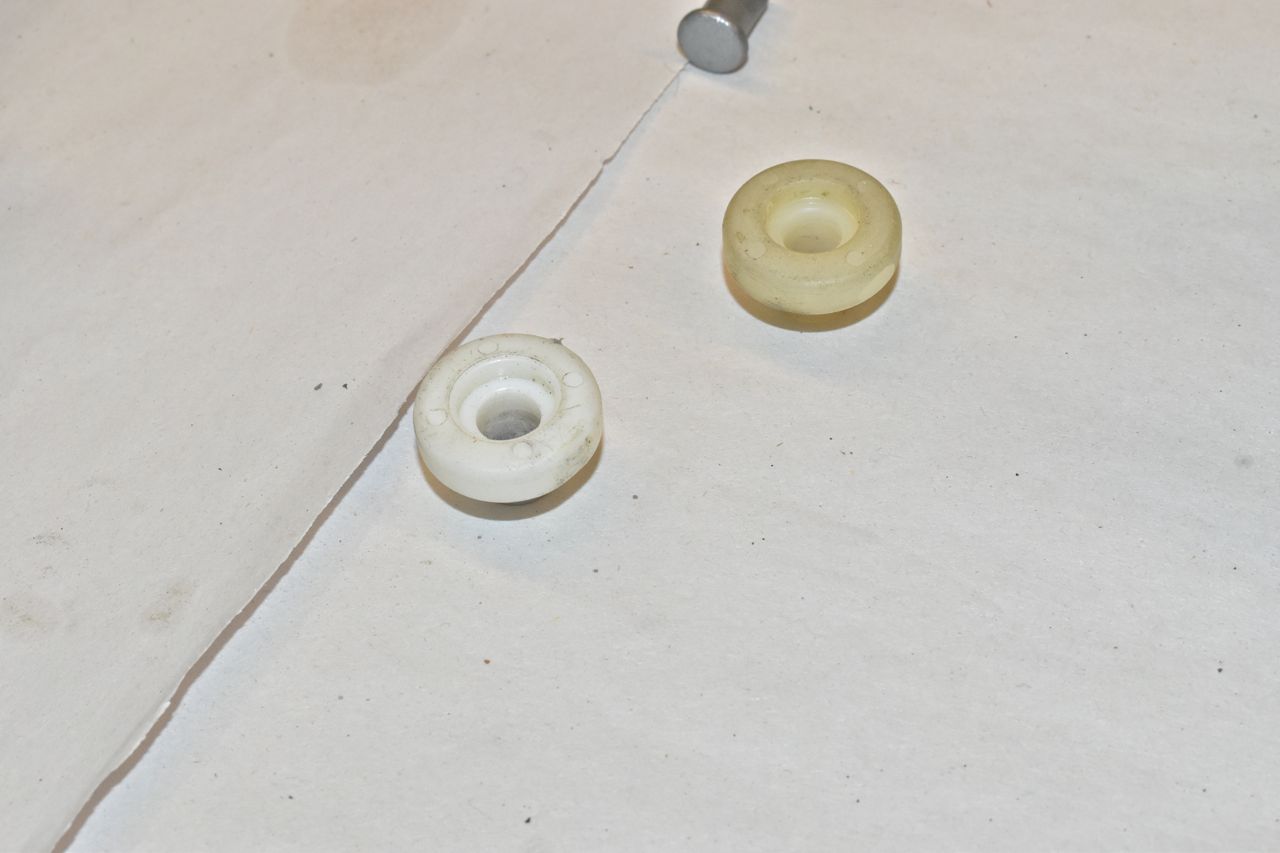

These are the new rollers I used of which then ended up being problematic.

The black regulator (Franken-regulator) compared to the actual OEM regulator at the bottom. After I made Franken-regulator I did find 2 OEM passenger door regulators exceptionally cheap so now I had something to compare it too. Naturally I tested Franken-regulator out in an actual door with window. I used the door on the 1966 galaxie 500 XL that the body is on the jig still.

I gave it a functional test that really only encompassed a couple dozen cycles as it worked just like it was supposed to. Now I have those tracks in the door and window cleaned and lubed. However when I removed Franken-regulator this is what I noticed on the roller on the main arm end.

If you look at the 3 O'Clock position there is a noticeable flat spot. This is after only 2 dozen cycles in a clean and lubed track. This is unacceptable. What is it going to look like after a couple thousand cycles? Then add small amounts of dirt and dust that accumulates in the track. This simply will not last in a daily driver.

This is another look at the right side.

As a sanity check and good comparison I dug through all my spare window regulators (dozen or so) and found the worse looking original Ford roller from the 1960's to see how held up with no doubt thousands of cycles and in dirty and dried out tracks. This is the worst OEM roller I could find. It basically has a clean spot on it. No actual perceivable flat spot.

Since there is no material specification on the reproduction rollers I can only assume, if it is indeed nylon, it's not 6/6, or it's another softer polymer. It really doesn't matter as I had to come up with another solution to the aftermarket problem. I mean what's the point of going on if the rollers aren't going to last more than 6 months of daily use. Each of the '66 and '68 Fords use about 24 rollers for all 4 windows. That means approximately 72 rollers to complete all 3 cars ('66 LTD, '68 XL and the '66 gal 500 XL). There's another aspect of this problem, I am not paying 5 dollars x 72 for rollers that wear out quickly. Everything came to a screeching halt until I solved this.

I have a high temperature 3D printer that can print in a copolymer of Nylon 6 and Nylon 6/6. So I decided to try a prototype and run it in the door for 400 cycles with a dry track to simulate accelerated wear. Given that, I needed to model the roller in 3D CAD first, then run it through CAM and finally print some out. Pictured above is the roller modeled from just measuring the old OEM ones with a vernier caliper.

With the roller being on the small side even with a fine resolution 3D printer the parts will require some post processing to clean up and approach the actual 3D CAD image. 3D printing should only be used for small runs, even making 72 was a vampire time suck.

Printing the rollers and post processing was just part of the puzzle to solve. I had to reuse the old roller axles, however they are swaged in and after removing the swage there is no material to reattach to the arms. The only solution that presented itself was to centre drill each one in the lathe and tap for 6-32 machine screw and now they are reusable. Again another vampire time suck.

I refitted Franken-regulator with my homemade nylon6-nylon6/6 rollers and reused axles and installed it back in the 1966 galaxie 500 XL door and ran it for 400 cycles completely up and completely down hitting hard on the stops each time. Also the tracks were devoid of any lubrication, so the rollers and tracks were dry.

The results for the homemade rollers were great. After 400 dry cycles they had no flat spots on them. At last I had a solution for long term rollers. However another problem presented itself. The brand new ACI power window motor I was using started developing a knock around 150 cycles in and by 400 cycles every time I reversed direction of the glass it sounded like someone took a hammer to the door.

Serenity now please! (rolling eyes)

OK now to figure out the electric motor situation. Again this gets pretty convoluted so hang in there as I try to present this properly.

Now about 3-4 years ago I bought 8 ACI motors to do two of the Ford cars. I recently bought another 4 ACI motors for the '68 XL. The latest batch of 4 I bought I noticed had visually changed from the previous 8 I bought. For the roller test I was using the 1 of the older batch of 8 ACI motors. All the ACI motors used a plastic armature end play adjustment screw. What was happening with the older batch of 8 NOS ACI motors is the plastic end play screws ACI used disintegrated. It was a poor plastic and just came apart like sticking a screwdriver into a candle and twisting. I couldn't even get the old plastic out with a screwdriver I had to melt each one out.

It was a mess.

Click here to continue to part 94